Adjustable non-Newtonian fluid deceleration strip

A technology of non-Newtonian fluids and speed bumps, which is applied to roads, road signs, traffic signals, etc., can solve the problems of lack of adjustment mechanisms, and achieve the effect of avoiding damage and improving the vibration feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

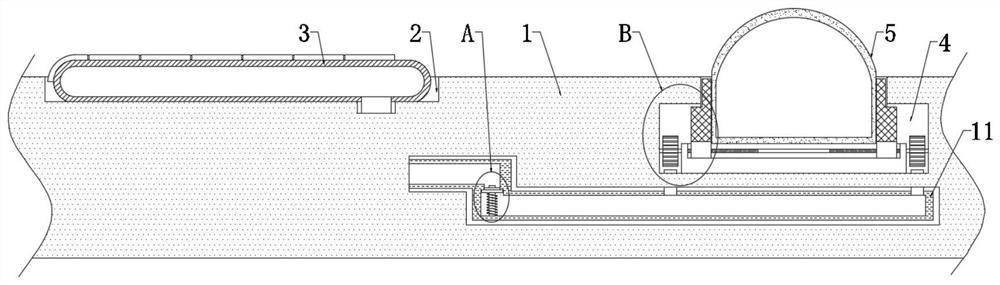

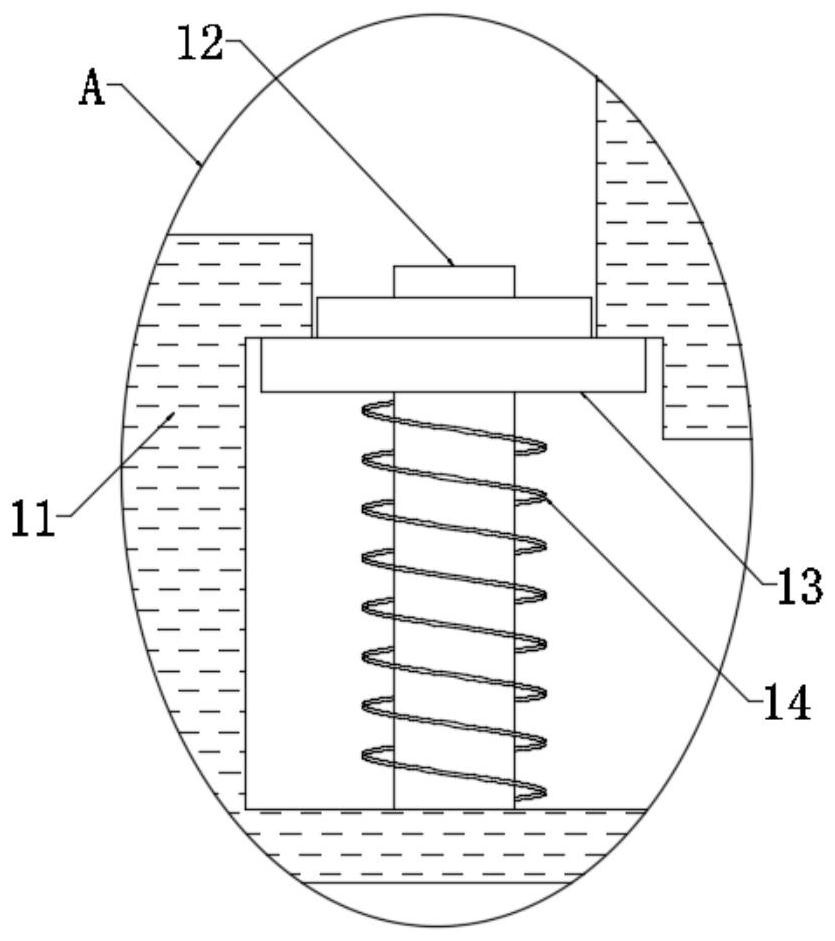

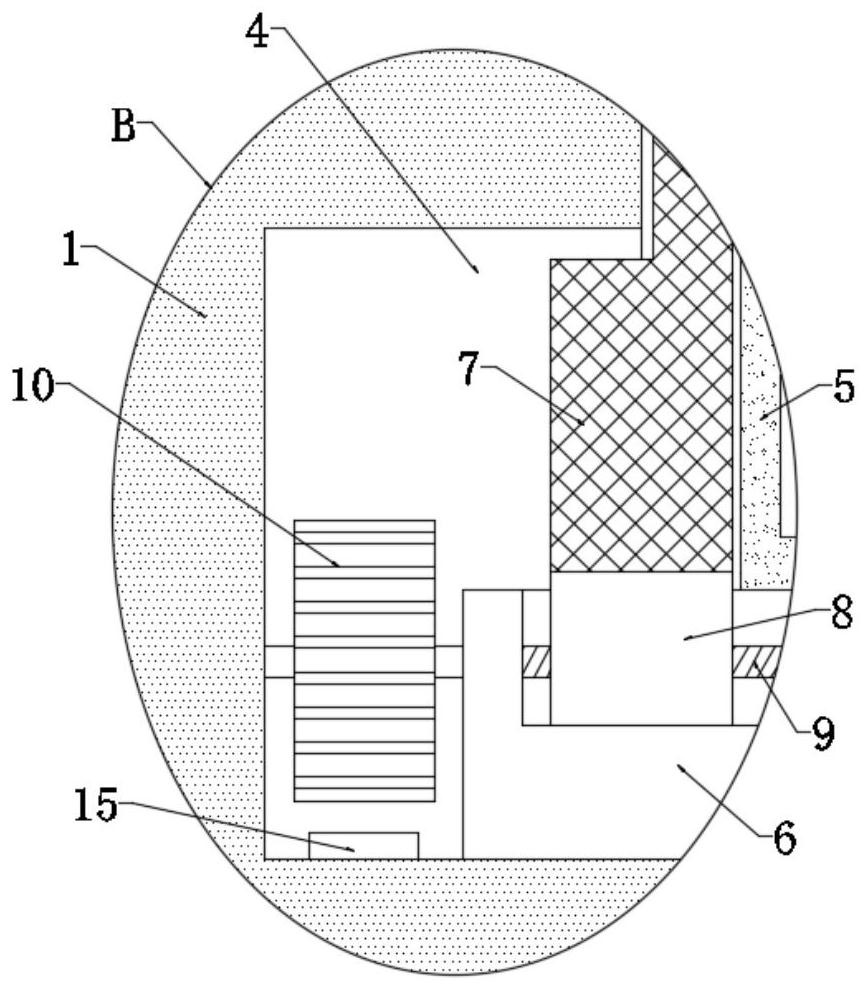

[0030] refer to Figure 1-3 , an adjustable non-Newtonian fluid speed bump, including a plurality of grooves 2 and a device groove 4 arranged on the upper end of the roadbed 1, the plurality of grooves 2 and the device groove 4 are misplaced, and the inside of the groove 2 is provided with a flat The elastic airbag 3, the upper surface of the elastic airbag 3 is evenly laid with a plurality of pressure plates, all of which are flexibly connected, and the interior of the subgrade 1 is also provided with a Z-shaped air guide tube 11, and the diameter of the Z-shaped air guide tube 11 is large enough , can allow a large amount of gas to pass through quickly, one end of the Z-shaped air duct 11 is connected with one end of the elastic air bag 3, the inside of the device tank 4 is provided with a bottom plate 6, and the bottom sides of the device tank 4 are respectively provided with nozzles 15, Z The other end of the type air duct 11 communicates with two nozzles 15, and the upper...

Embodiment 2

[0036] refer to Figure 4-5 , the present embodiment is different from Embodiment 1 in that: the interior of the subgrade 1 is also provided with an oblique air guide pipe 16, one end of the oblique air guide pipe 16 communicates with the Z-shaped air guide pipe 11, and the other end of the oblique air guide pipe 16 Connected with the next elastic airbag 3, the inside of the oblique air guide tube 16 is provided with a one-way valve 17, the gas flowing out from the previous Z-shaped air guide tube 11 will be stored inside the next elastic air bag 3, and the one-way valve 17 can avoid The gas flows back, thereby increasing the gas storage capacity inside the next elastic airbag 3 .

[0037]The working principle of this embodiment: if the vehicle passes through multiple non-Newtonian fluid speed bump bodies 5 at a faster speed and has no intention of decelerating, the gas part inside the previous elastic airbag 3 flows into the oblique air duct 16 through the Z-shaped air duct 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com