Nozzle block, air spinning device and air spinning machine

A technology of air spinning and nozzle block, which can be used in spinning machine, continuous winding spinning machine, textile and paper making, etc., can solve the problems of increasing pressure loss and difficulty in making nozzles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

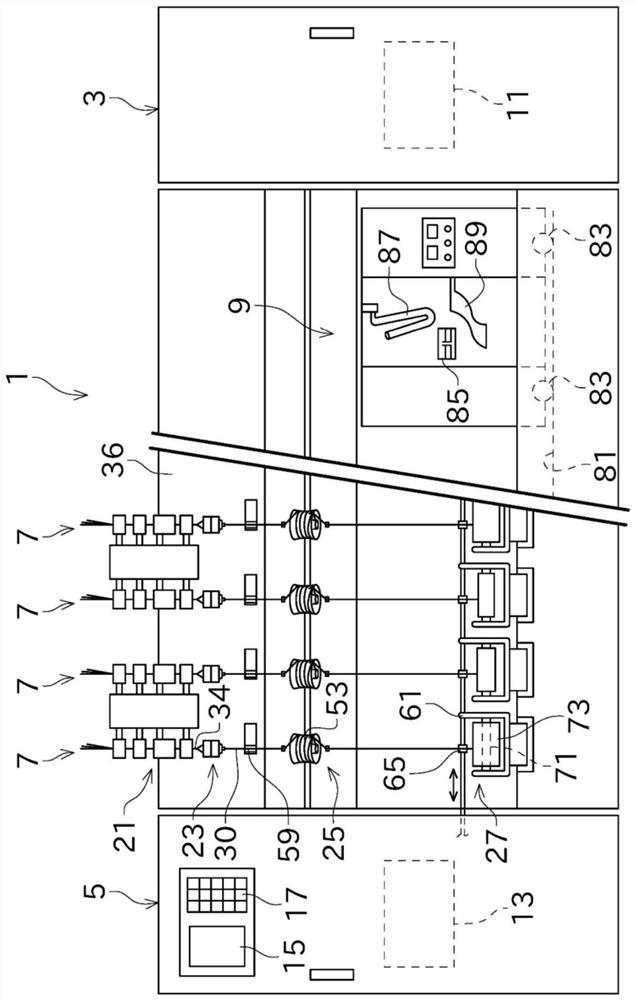

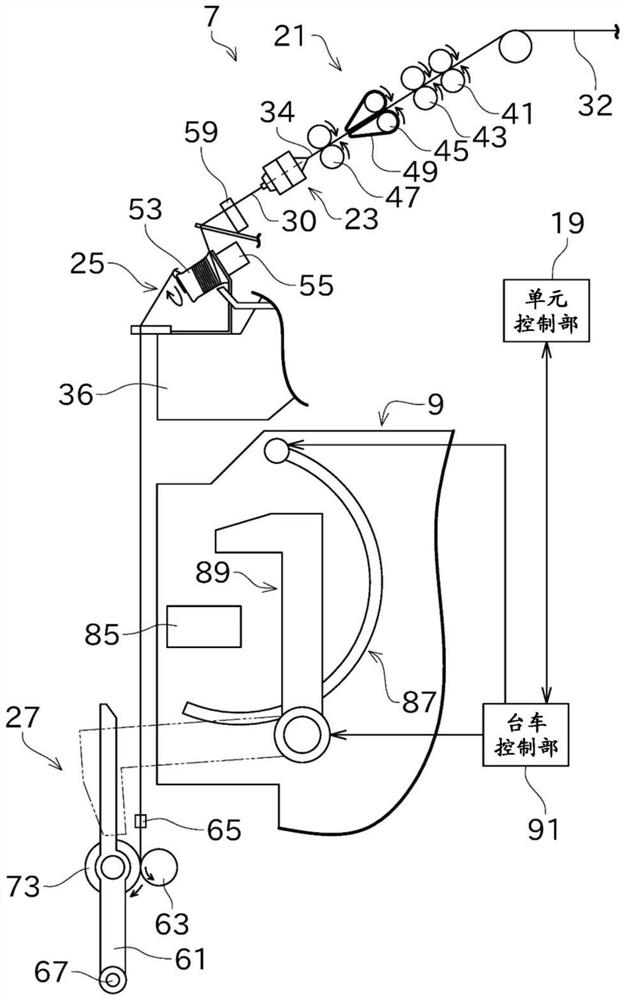

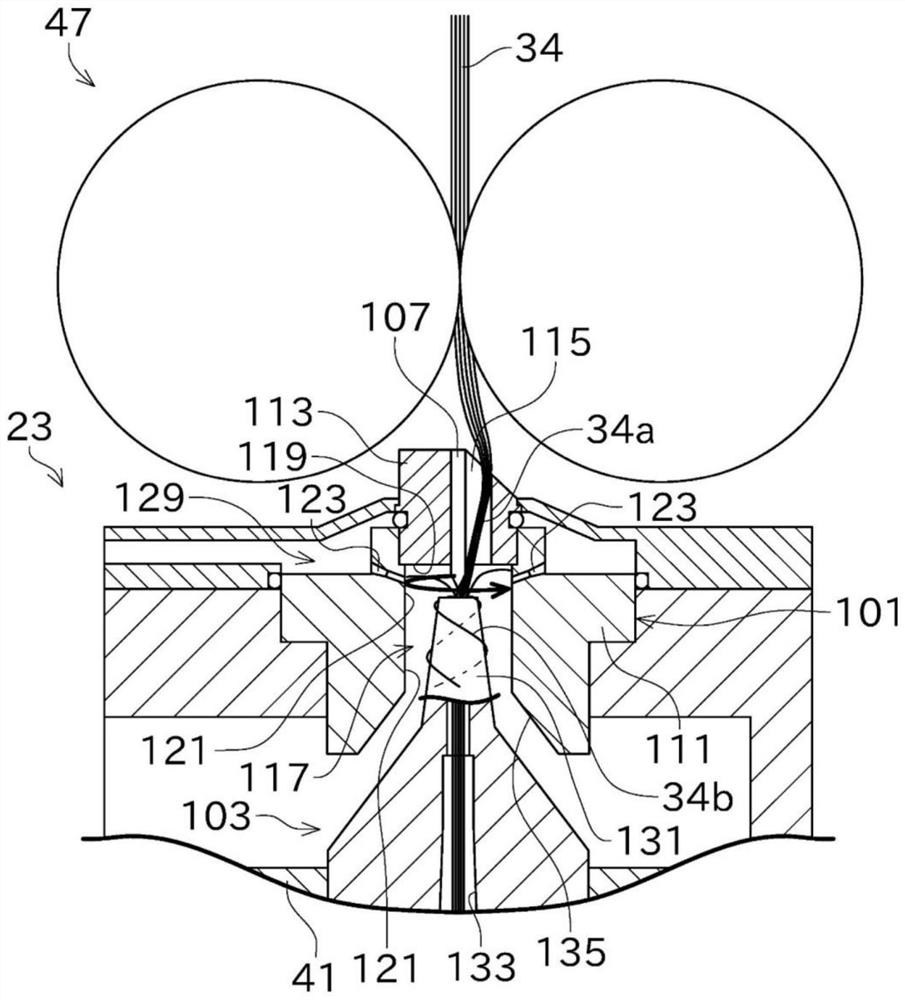

[0036] Next, refer to figure 1 and figure 2 The air spinning machine 1 including the air spinning device 23 including the nozzle block 101 according to the first embodiment of the present invention will be described.

[0037] Such as figure 1 As shown, the air spinning machine 1 includes a blower box 3 , a prime mover box 5 , a plurality of spinning units 7 , and a yarn joining cart 9 . The plurality of spinning units 7 are arranged side by side in a predetermined direction.

[0038] A blower 11 and the like functioning as a negative pressure source are arranged in the blower case 3 .

[0039] A drive source (not shown), a central control unit 13 , a display unit 15 , and an operation unit 17 are arranged in the prime mover case 5 . The driving source provided in the prime mover case 5 includes a motor commonly used by the plurality of spinning units 7 .

[0040] The central control device 13 centrally manages and controls each part of the air spinning machine 1 . Such ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com