Water-based paint for anticorrosion treatment of copper pipes of two devices of air conditioner and preparation method of water-based paint

A water-based coating and anti-corrosion treatment technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of uncoated, easy to fall off, poor anti-corrosion effect of coatings, etc., to improve coating viscosity, Improve coating performance and good adhesion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

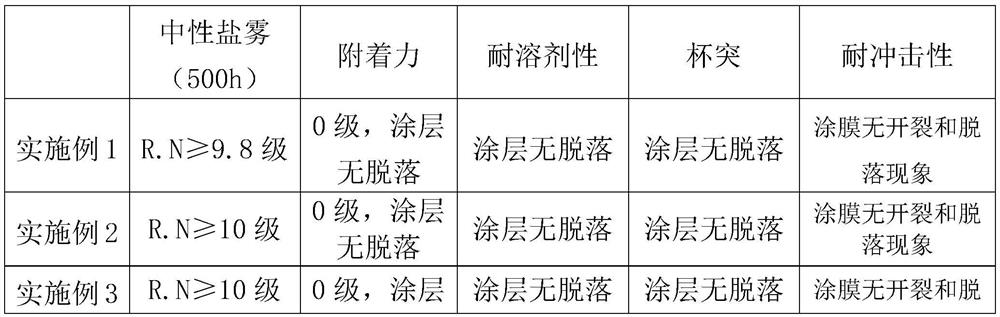

Examples

preparation example Construction

[0035] Among the present invention, the synthetic method of waterborne epoxy modified acrylic resin comprises the steps:

[0036] Use water-soluble acrylic resin as the base, start stirring, blow nitrogen for 5-10 minutes, heat up to 90-110°C, then put epoxy resin into the reaction kettle, heat up to 110-130°C after adding, and keep warm at this temperature 10-30min;

[0037] Add acrylic acid monomer and phosphorous-containing monomer into the reaction kettle, keep warm at 110-130°C for 10-40min, add peroxide initiator, ethylene glycol butyl ether and isoparaffin solvent mixture dropwise, and then in 110- After heat preservation at 130°C for 1-3h, the material is cooled and discharged.

[0038] Wherein, the molecular weight of water-soluble acrylic resin is 1000-10000, preferably, its molecular weight is 5000-8000; Preferably, the formula of water-soluble acrylic resin is selected from Chinese patent application CN107904586A, and it comprises the following composition by weig...

Embodiment 1

[0050] A kind of water-based coating for anticorrosion treatment of copper tubes of two air conditioners, comprising the following components in parts by weight:

[0051] 15 parts of water-based epoxy-modified acrylic resin, 0.2 part of organic amine, 10 parts of low-temperature baking curing agent, 4 parts of adhesion promoter, 0.2 part of wetting agent, 0.1 part of leveling agent, 70.5 parts of water;

[0052] Wherein, water-based epoxy-modified acrylic resin comprises the following components by weight:

[0053]50 parts of water-soluble acrylic resin, 15 parts of epoxy resin, 4 parts of acrylic acid, 5 parts of phosphorus-containing monomers, 0.5 parts of peroxide initiator, 3 parts of butyl glycol ether, and 2 parts of isoparaffin solvent.

[0054] In the present embodiment, the synthetic method of waterborne epoxy-modified acrylic resin comprises the steps:

[0055] Use water-soluble acrylic resin as the base, start stirring, blow nitrogen for 5-10 minutes, heat up to 90...

Embodiment 2

[0059] A kind of water-based coating for anticorrosion treatment of copper pipes of two air conditioners, comprising the following components in parts by weight:

[0060] 23 parts of water-based epoxy-modified acrylic resin, 0.5 part of organic amine, 12 parts of low-temperature baking curing agent, 6 parts of adhesion promoter, 0.5 part of wetting agent, 0.05 part of leveling agent, and 57.95 parts of water;

[0061] Wherein, the water-based epoxy-modified acrylic resin includes the following components in parts by weight:

[0062] 60 parts of water-soluble acrylic resin, 8 parts of epoxy resin, 3 parts of acrylic acid, 2 parts of phosphorus-containing monomers, 0.2 parts of peroxide initiator, 2 parts of ethylene glycol butyl ether, and 1 part of isoparaffin solvent.

[0063] In the present embodiment, the synthetic method of waterborne epoxy-modified acrylic resin comprises the steps:

[0064] Use water-soluble acrylic resin as the base, start stirring, blow nitrogen for 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com