Preparation method of high-strength porous sound insulation board

A sound insulation board and high-strength technology, applied in the field of sound insulation materials, can solve the problems of large raw materials, restrict the use environment, increase the difficulty of installation, etc., and achieve the effect of enhancing the compressive mechanical strength, expanding the scope of use, and not easy to shake at will.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

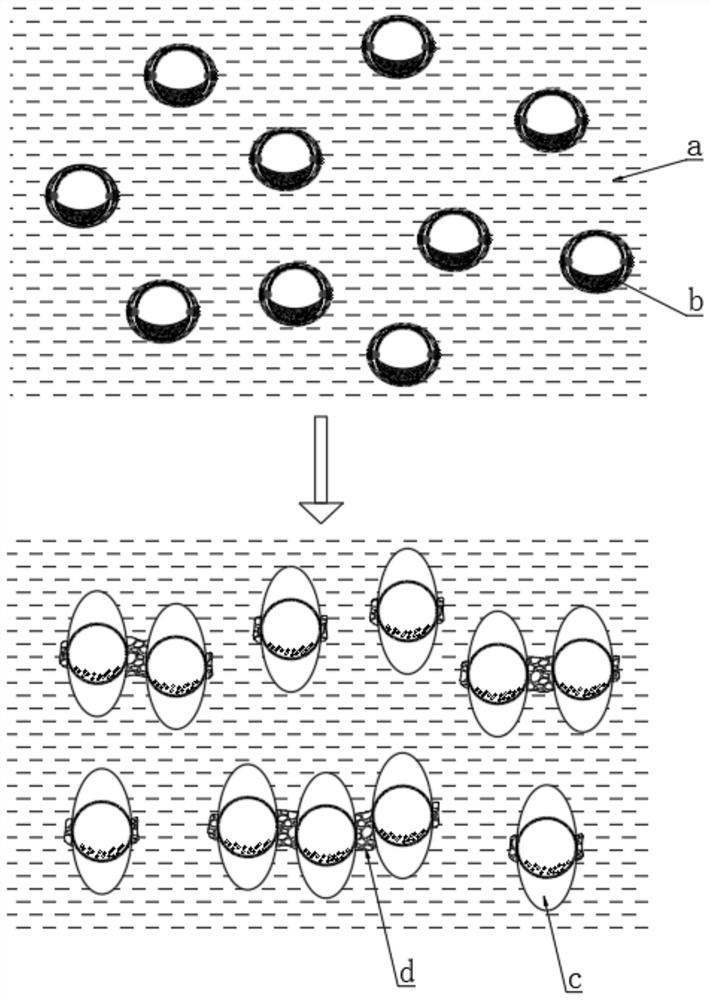

[0048] see figure 1 , a preparation method of a high-strength porous sound insulation board, comprising the following steps:

[0049] S1. Mixing: add oriented hole-forming balls ( figure 1 Among them, a represents the liquid raw material, b represents the oriented hole ball), continue to stir evenly, and then inject it into the mold for molding, and the mold is made of high temperature resistant material;

[0050] S2. Primary heating: The mold and the raw material are heated at the first stage, the heating temperature is 65°C, and the heating time is 40 minutes. The oriented hole-forming balls in the raw material undergo double changes in sequence;

[0051] S3. Double change: The surface of the oriented hole-forming ball first melts, so that the heating temperature is transferred to the inside, and then the internal decomposition generates gas, and the oriented hole-forming ball expands into an ellipsoid in the vertical direction, and realizes orientation and shaping of pores...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com