Process and device for efficiently treating mixed raw material biogas slurry

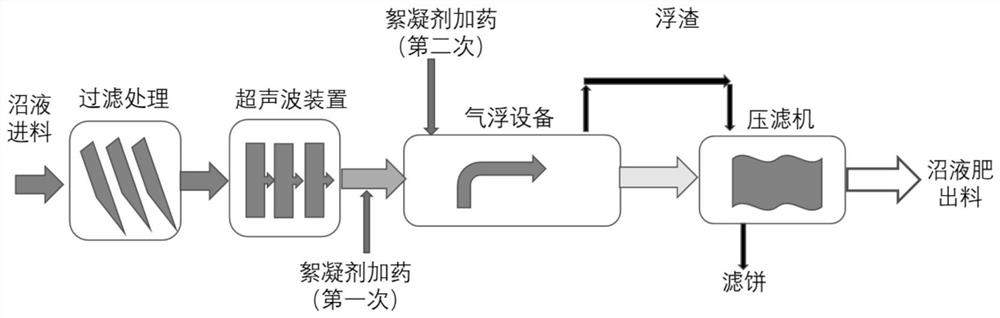

A technology of mixing raw materials and biogas slurry, which is applied in filtration treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems such as the inability of flocs to float completely, the cost is high, and the requirements cannot be met, and the treatment cost can be reduced. , Long shelf life, the effect of meeting the needs of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

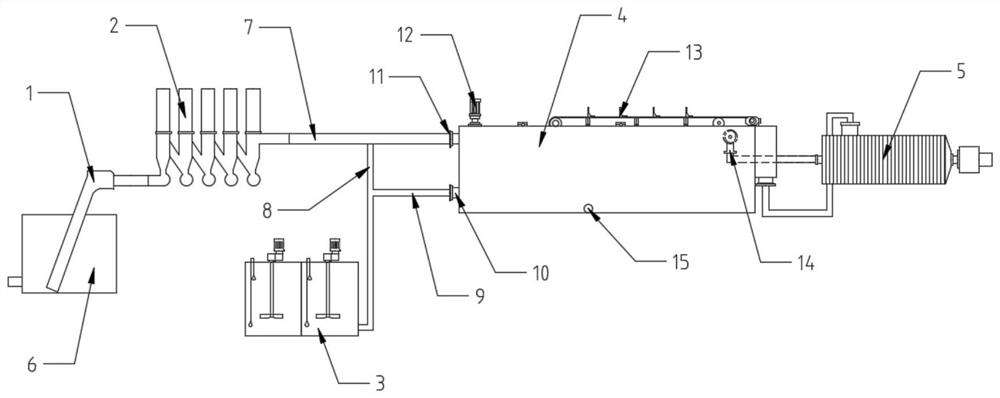

[0041] Example 1: Using a device for efficient treatment of mixed raw material biogas slurry to treat pig manure biogas slurry with the following process, the process steps include:

[0042] S1. Primary filtration, the filtration accuracy of S1 primary filtration is 1mm, which is used to filter impurities such as hair, plant fiber, food residue, sand and gravel in biogas slurry;

[0043] S2. Ultrasonic dispersal. In S2 ultrasonic dispersal, the ultrasonic frequency is 20KHz and the wavelength is 0.0179m, which is used to break the large particle colloid in the biogas slurry and prepare for the subsequent flocculation and air flotation;

[0044] S3. Dosing flocculation for the first time: add flocculant to the biogas slurry delivery pipeline, the flocculant added for the first time to the biogas slurry is fully mixed in the pipeline, the mixing time is 10s, the volume of the flocculant is 1.2% of the volume of the biogas slurry, The concentration of the flocculant is 0.08%, whi...

Embodiment 2

[0048] Example 2: Use the device for efficient treatment of mixed raw material biogas slurry to treat pig manure biogas slurry with the following process, the process steps include:

[0049] S1. Primary filtration, the filtration accuracy of S1 primary filtration is 1mm, which is used to filter impurities such as hair, plant fiber, food residue, sand and gravel in biogas slurry;

[0050] S2. Ultrasonic dispersal. In S2 ultrasonic dispersal, the ultrasonic frequency is 40KHz and the wavelength is 0.009m, which is used to break the large particle colloid in the biogas slurry and prepare for the subsequent flocculation and air flotation;

[0051] S3. Dosing flocculation for the first time: add flocculant to the biogas slurry delivery pipeline, the flocculant added for the first time in the biogas slurry is fully mixed in the pipeline, the mixing time is 15s, the volume of the flocculant is 1.8% of the volume of the biogas slurry, The concentration of the flocculant is 0.12%, whic...

Embodiment 3

[0055] Embodiment 3: Use the device for high-efficiency treatment of mixed raw material biogas slurry to treat pig manure biogas slurry with the following process, and the process steps include:

[0056] S1. Primary filtration, the filtration accuracy of S1 primary filtration is 1mm, which is used to filter impurities such as hair, plant fiber, food residue, sand and gravel in biogas slurry;

[0057] S2. Ultrasonic dispersal. In S2 ultrasonic dispersal, the ultrasonic frequency is 30KHz and the wavelength is 0.011m, which is used to break the large particle colloid in the biogas slurry and prepare for the subsequent flocculation and air flotation;

[0058] S3. Dosing flocculation for the first time: add flocculant to the biogas slurry delivery pipeline, the flocculant added for the first time in the biogas slurry is fully mixed in the pipeline, the mixing time is 12s, the volume of the flocculant is 1.5% of the volume of the biogas slurry, The concentration of the flocculant i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com