Turning clamp structure for thin sheet parts with deflection and using method of turning clamp structure

A technology of parts and thin slices, which is applied in the field of lathe fixture structure with disturbance, can solve the problems of uneven positioning surface, difficult clamping, difficult positioning, etc., and achieve the advantages of increased overall strength, high production efficiency and low production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

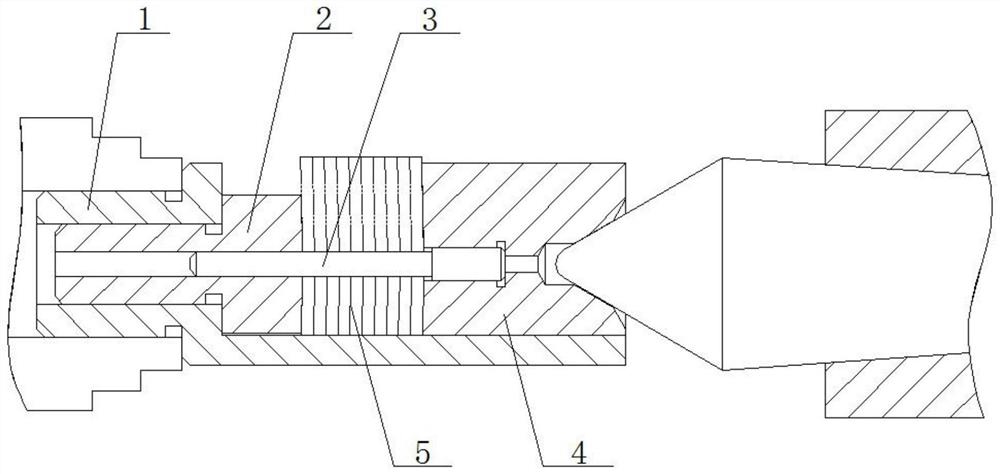

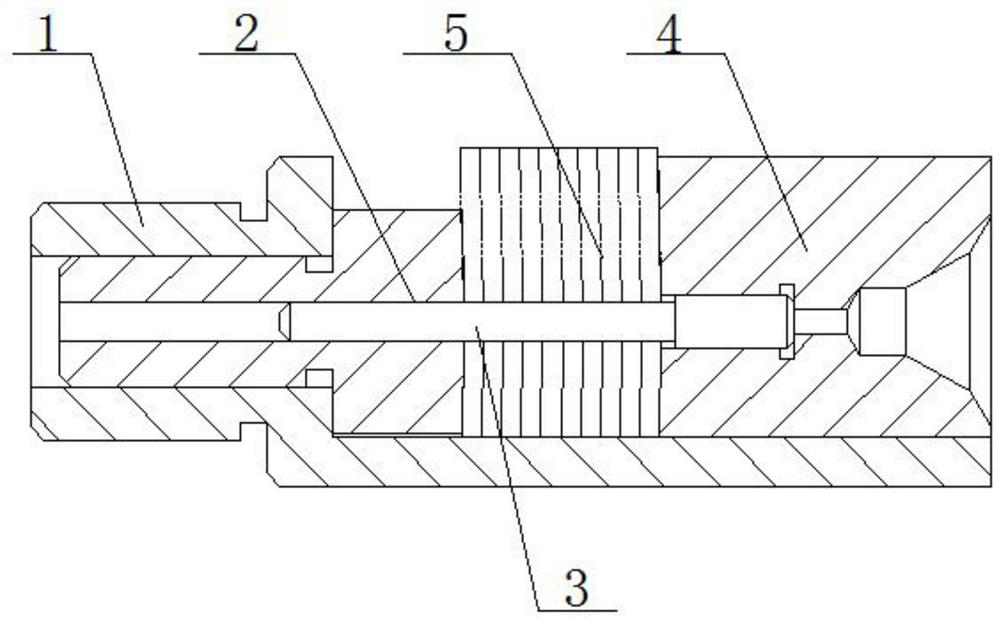

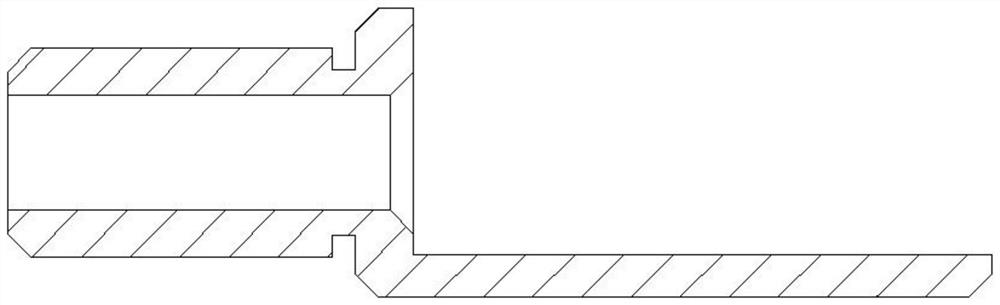

[0033] Embodiment of the present invention: a laminar part turning fixture structure with disturbance, as attached Figure 1-9As shown, it includes a clamping rod 1, the lower end of one side of the clamping rod 1 is provided with a horizontally protruding support plate, and the inside of the clamping rod 1 is provided with a positioning bush fixing hole along its length direction, and the positioning bush fixing hole is It is used to fix the positioning bush 2. There is a positioning mandrel penetration hole inside the positioning bushing 2, which is used to penetrate the positioning mandrel 3. It also includes a pressing block 4 placed on the other end of the support plate. The pressing block 4 One end facing the positioning bush 2 is provided with a positioning mandrel fixing hole, the tail of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com