Bar rolled steel finishing collecting system and collecting method thereof

A collection system and bar technology, applied in the direction of metal rolling, metal rolling, metal processing equipment, etc., can solve the problems of large equipment impact, increased bar bending, product quality and service life, etc., to improve work The effect of improving efficiency, reducing bar drop, and improving packaging quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing, the present invention will be further described by examples.

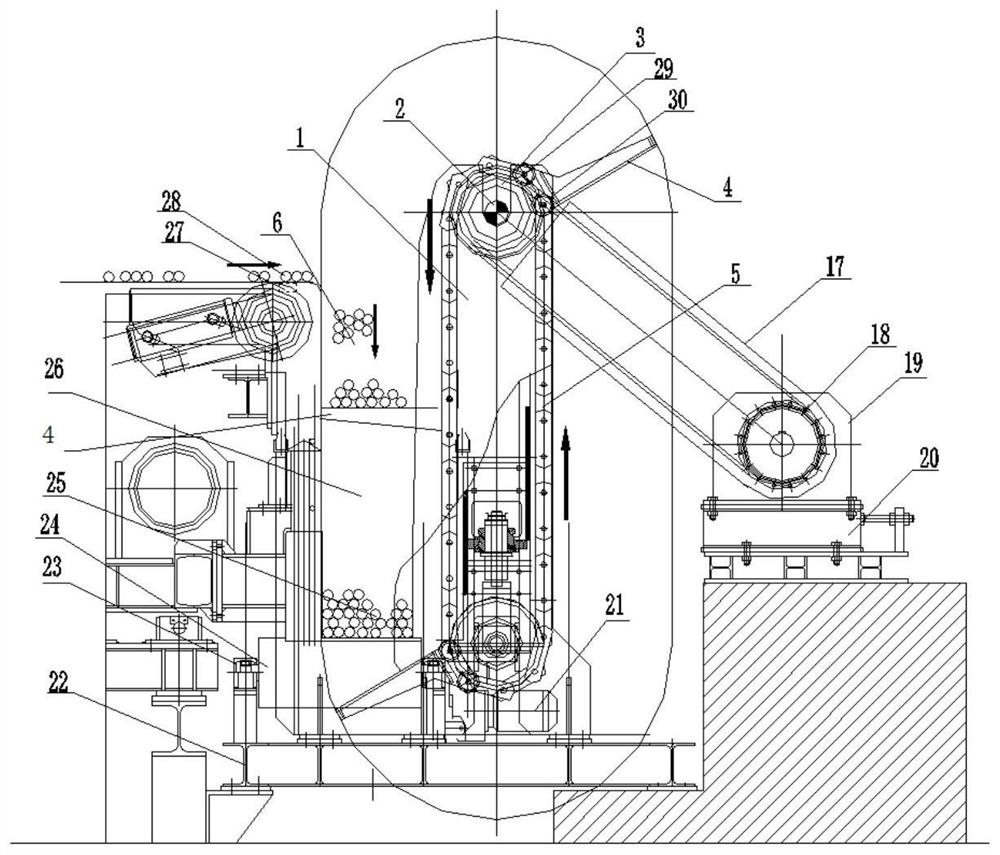

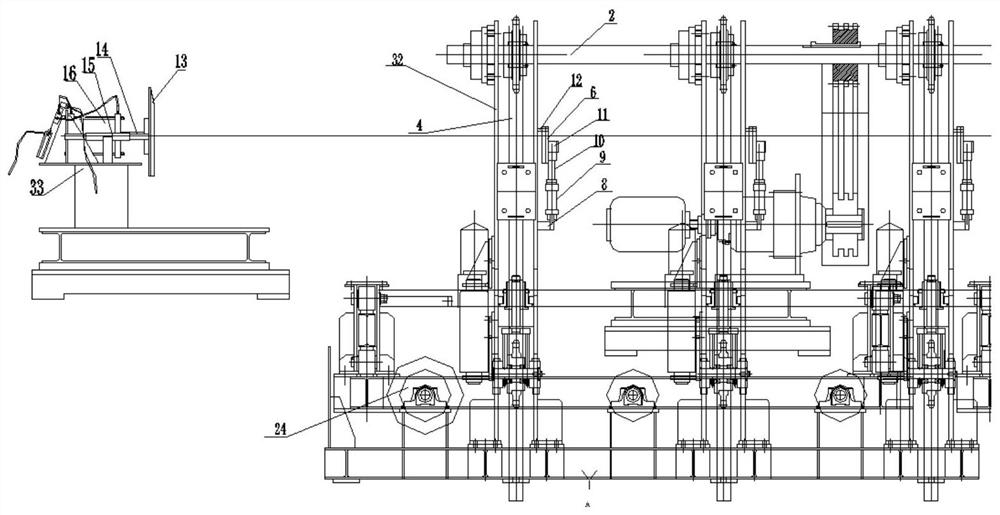

[0036] Refer to attached Figure 2-15 , a finishing and collecting system for bar rolling, comprising a vertical falling steel machine 1, a conveying roller table 24, a collecting tank 26 and a chain conveyor 34, and the end of the chain conveyor 34 is provided with a plurality of collecting tanks 26 arranged side by side And the vertical falling steel machine 1 matched with each collecting tank 26, the collecting tank 26 is U-shaped, and the bottom of the U-shaped collecting tank 26 is provided with a conveying roller table 24, and the vertical falling steel machine 1 includes a transmission shaft 2. The transmission gear 3, the supporting arm 4, the chain 5, the transmission belt 17, the transmission motor 19 and the driven sprocket, the transmission motor 19 is driven and connected with the transmission gear 3 through the transmission belt 17, and the transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com