High-automation strip-shaped tea intelligent stir-frying equipment

A bar-shaped tea, intelligent technology, applied in the direction of tea treatment before extraction, can solve the problems of tea quality, time-consuming and labor-intensive, easy to attach to the stirring rod, etc., to achieve the effect of ensuring the greening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

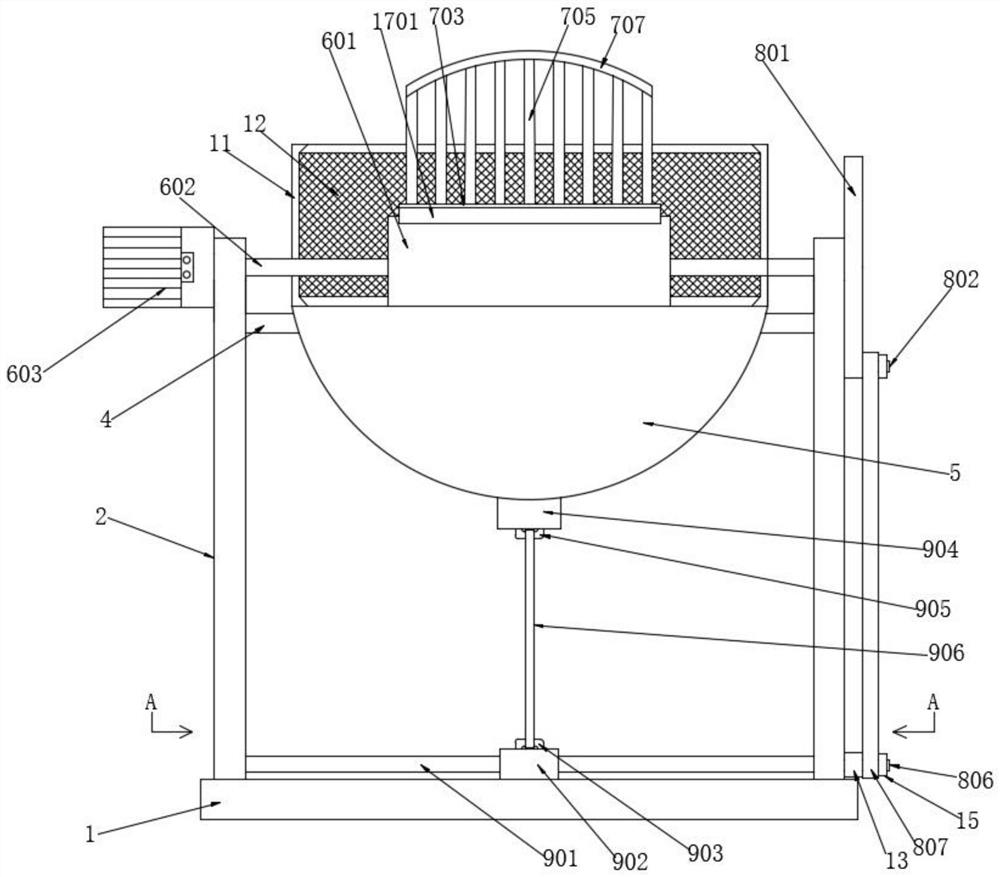

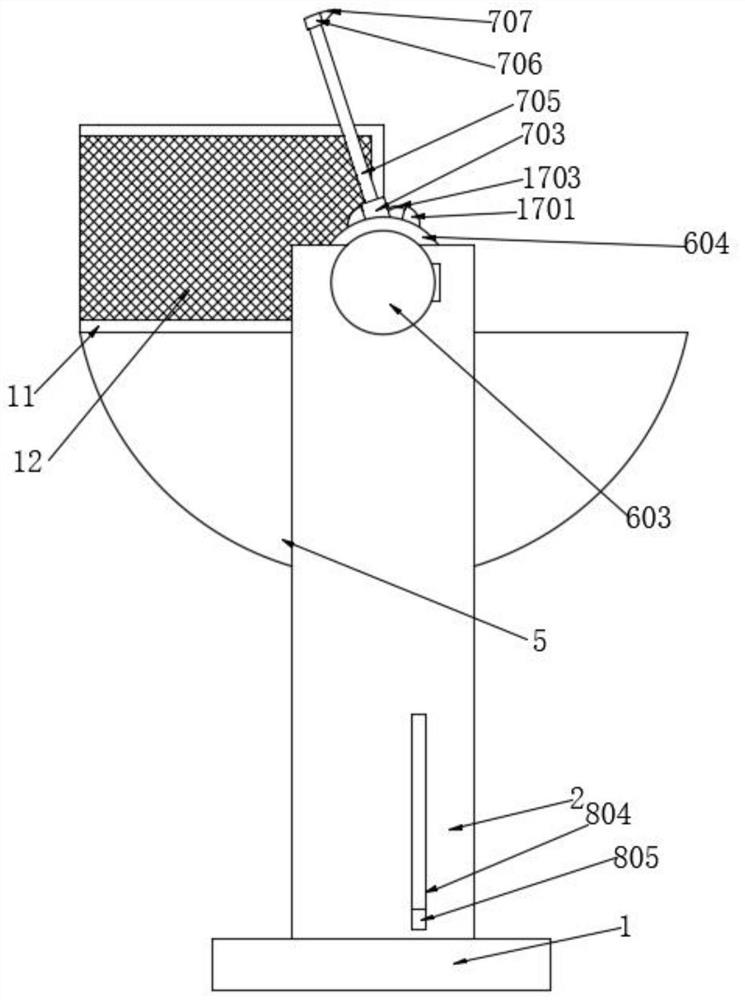

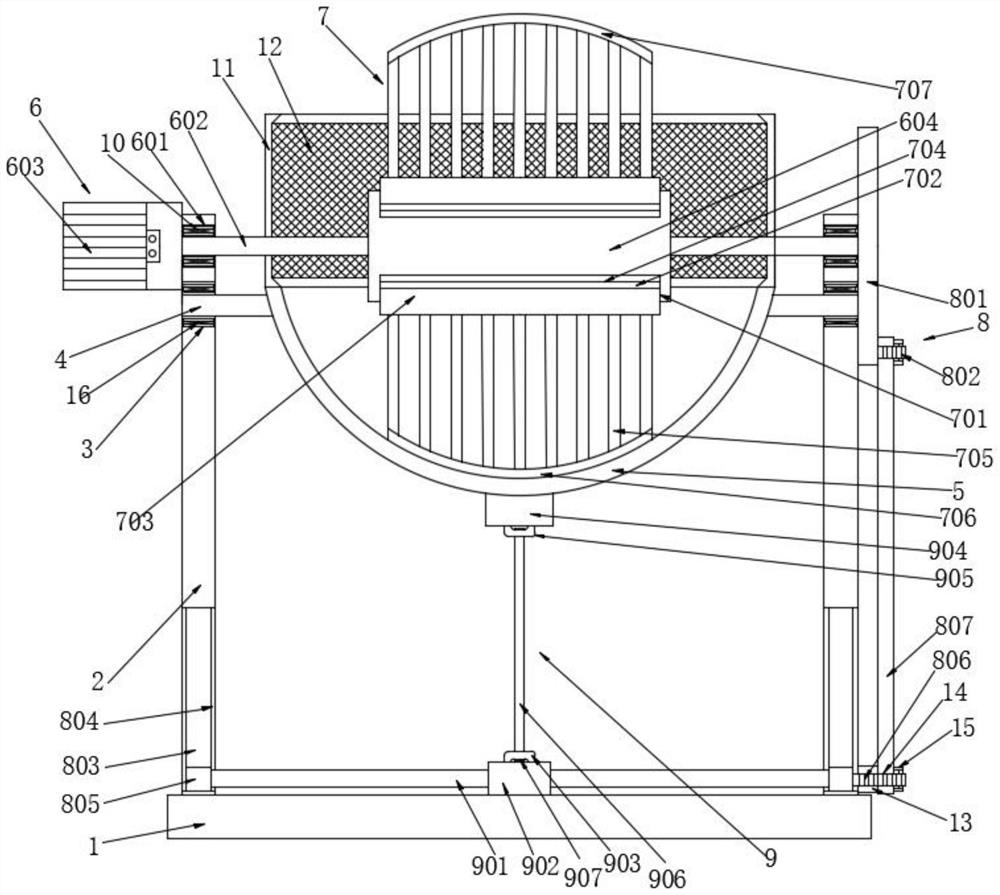

[0046] Example: such as Figure 1-6 As shown, the present invention provides the following technical solutions: a highly automated strip-shaped tea intelligent frying equipment, which includes a bottom plate 1, a vertical plate 2, a fixing hole 3, a connecting rod 4, and a frying pan 5. Power component 6, frying component 7;

[0047] Both sides of the upper end of the bottom plate 1 are symmetrically fixed with a vertical plate 2, and the upper middle position of the vertical plate 2 is provided with a fixed hole 3, and the fixed hole 3 is connected with a connecting rod 4 for rotation, and the connecting rod 4 can be rotated through the fixed hole 3. Simultaneously there will be no offset in the longitudinal position, a frying pan 5 is fixedly installed between the connecting rods 4, the frying pan 5 can rotate through the connecting rods 4, a power assembly 6 is fixedly connected to the frying pan 5, and the Component 6 can provide the power for frying component 7 to stir-f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com