Upender

A turning machine and frame technology, applied in the field of machinery, can solve the problems of breeding various pests, high labor intensity, bad environment, etc., and achieve the effect of reducing labor intensity, good effect, uniform and thorough turning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

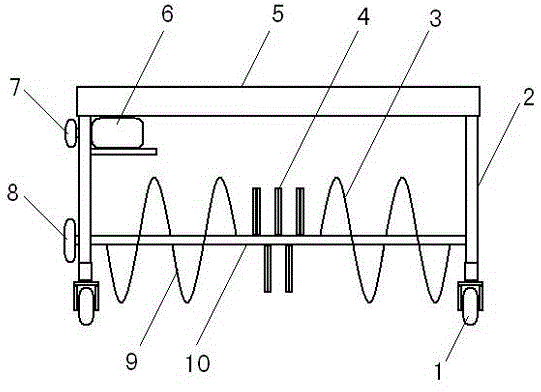

[0014] Such as figure 1 Shown, a kind of turning machine comprises ground wheel 1, frame 2, and frame 2 is cube-shaped, and frame 2 top is provided with shed plate 5, and shed plate 5 is rectangular, and shed plate 5 is used for blocking the flying material; the ground wheel 1 is set under the frame 2, and there are two kinds of ground wheels 1, namely, a walking wheel and a steering wheel, which are respectively placed at the front or rear of the frame (that is, the walking wheel can be placed at the front or the rear; the steering wheel can be placed at the front or at the rear), the travel motor (not shown in the figure) drives the sprocket C on the travel wheel through the chain, thereby driving the travel wheel, and then the machine automatically walks Main shaft 10 is also set on frame 2, and main shaft 10 is fixed on the frame 2 by bearing; On the main shaft 10, left and right ends are respectively provided with symmetrical right helical blade 3 and left helical blade 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com