Method for manufacturing electrical steel sheet product

A technology for electrical steel sheets and manufacturing methods, applied in chemical instruments and methods, layered products, metal layered products, etc., can solve the problems of high-temperature adhesion and poor high-temperature oil resistance of automobile drive motors, and achieve excellent high-temperature oil resistance. Excellent high temperature adhesion and high temperature oil resistance, the effect of reducing vibration and noise problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

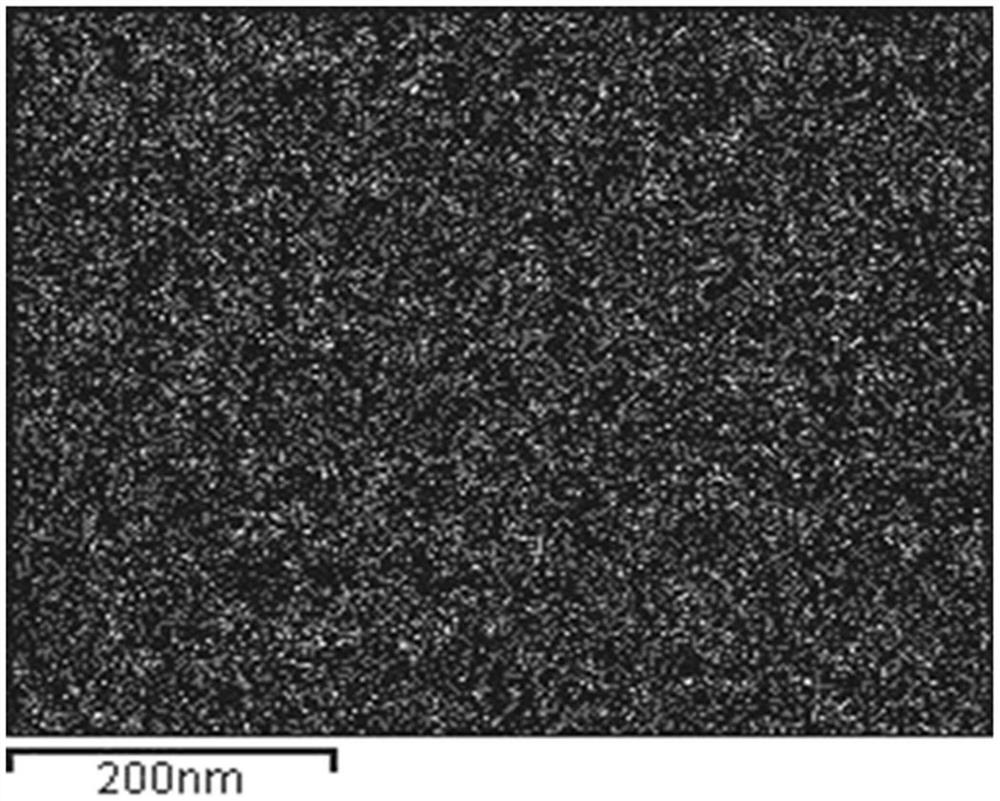

Image

Examples

Embodiment Construction

[0038] In the present specification, the first, second, and third and other terms are used in order to illustrate a variety of portions, ingredients, regions, layers, and / or cross-sections, but are not limited thereto. These terms are only used to distinguish some parts, ingredients, regions, layers, or cross-sections from other portions, components, regions, layers, or sections. Thus, the first portion, component, region, layer, or section described below can be said to be a second portion, component, region, layer or cross section in the limitation of the scope of the invention.

[0039] In the present specification, it is said that some part "includes" a constituent element, which means that other constituent elements may also be included as long as there is no particular opposition, and other components may also be included.

[0040] The professional terms used in this specification are only used for specific embodiments, and is not intended to limit the invention. As long a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com