Permanent magnet motor with motor cover easy to replace

A permanent magnet motor, motor cover technology, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of dust extrusion and hardening, and the rotation of the shaft is blocked.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

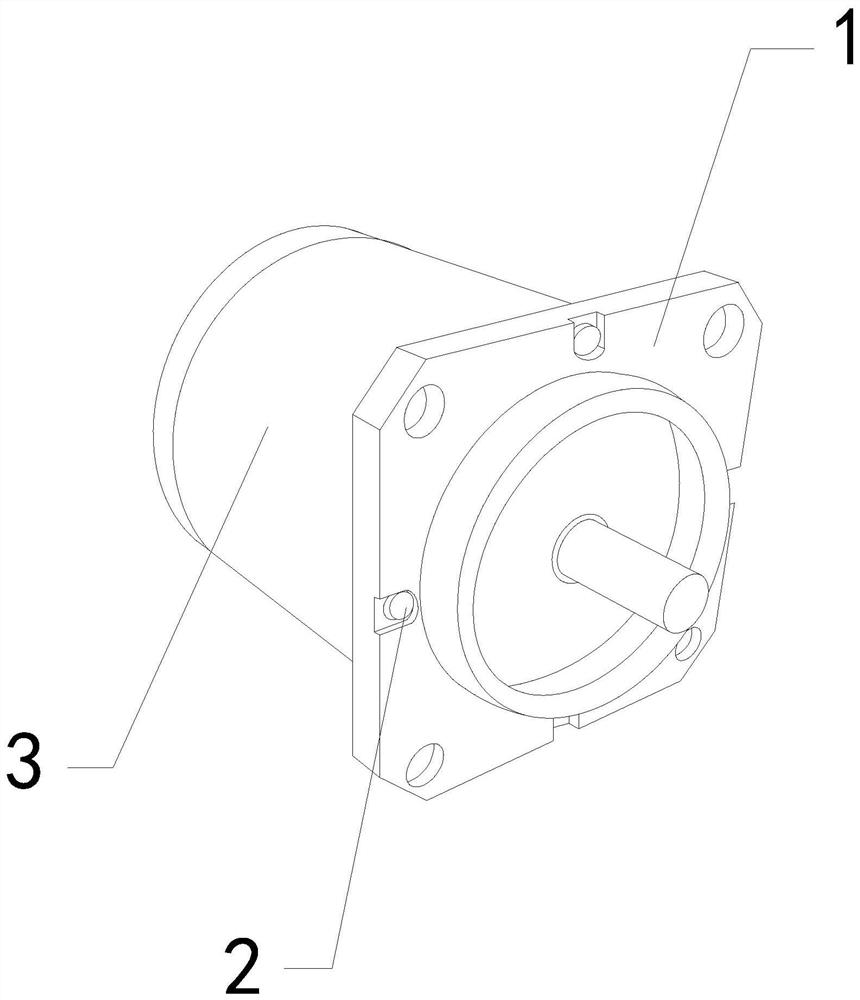

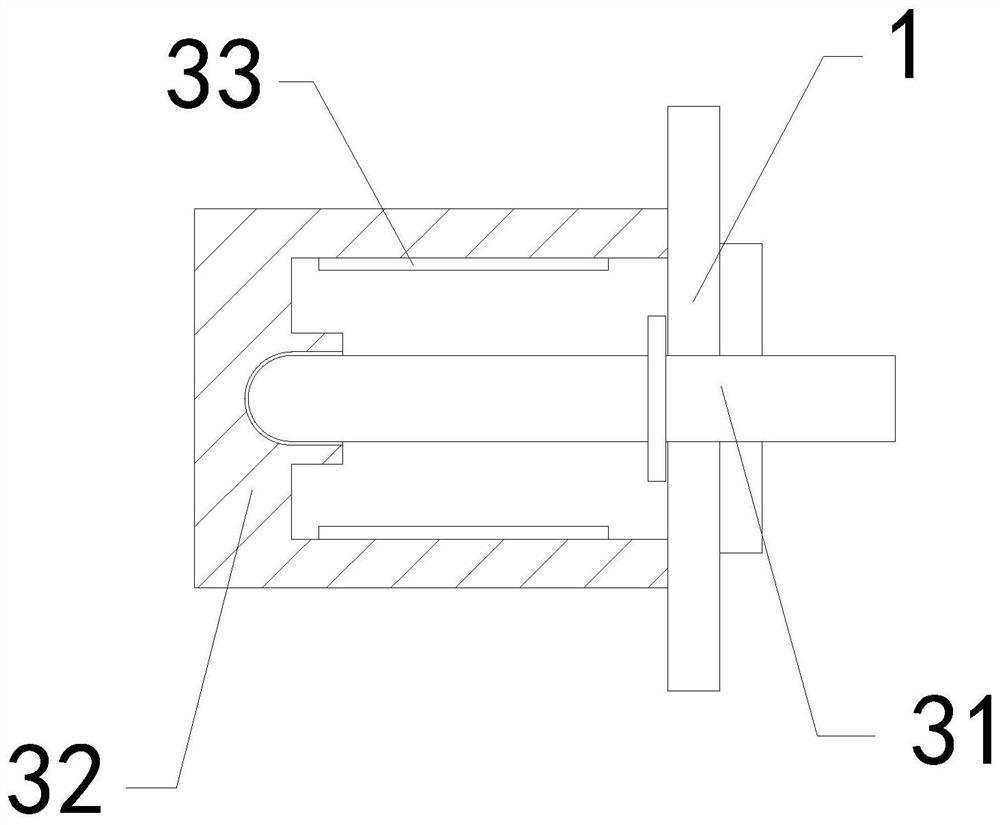

[0026] For example figure 1 -example Figure 5 Shown:

[0027] The present invention provides a permanent magnet motor that is easy to replace the motor cover. Its structure includes a motor cover 1, a fixing screw 2, and a motor 3. The fixing screw 2 is screwed to the motor cover 1, and the motor 3 is integrated with the motor cover 1. The motor 3 includes a rotating shaft 31, a casing 32, and a suction block 33, the rotating shaft 31 is movably engaged with the casing 32, and the suction block 33 is installed on the inner wall of the casing 32.

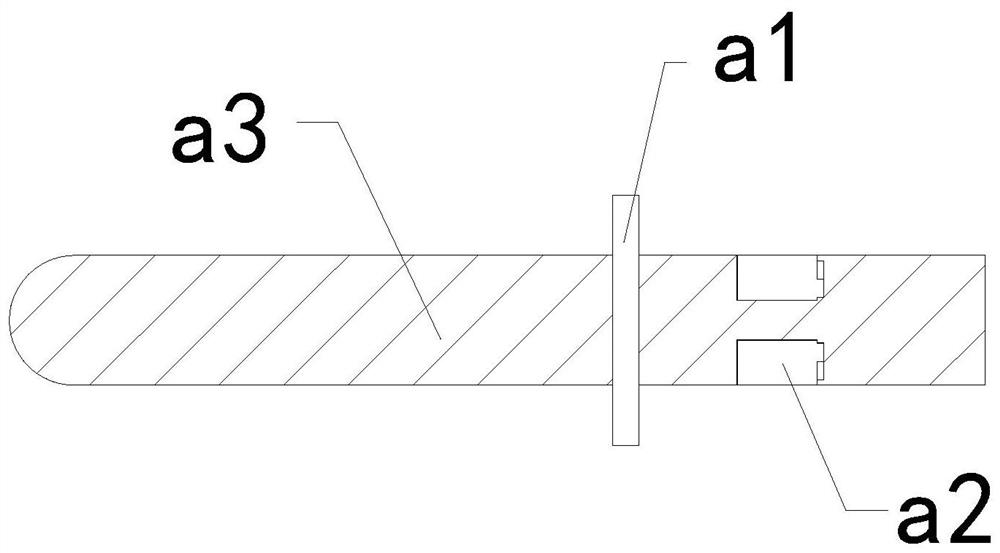

[0028] Wherein, the rotating shaft 31 includes a fixed plate a1, an overhanging block a2, and a rotating rod a3. The extending block a2 is movably engaged with the rotating rod a3. The rotating rod a3 and the fixing plate a1 are of an integrated structure. There are two overhanging blocks a2, and they are evenly distributed symmetrically on the rotating rod a3. The throwing force generated by the rotation of the mechanism can make...

Embodiment 2

[0034] For example Image 6 -example Figure 8 Shown:

[0035] Wherein, the contact reducing groove b1 includes a protruding frame b11, a middle solid block b12, and a frame body b13. In connection with each other, the extension frame b11 can be extended outward through the inertial force generated by the extension of the mechanism, so that the extension frame b11 can bounce off the dust layer inside it.

[0036] Wherein, the extension frame b11 includes an oil-absorbing block c1, a plate c2, and an air-drying mechanism c3, the oil-absorbing block c1 is embedded in the inner side of the plate c2, and the air-drying mechanism c3 is installed between the oil-absorbing block c1 and the plate c2, The oil-absorbing block c1 is made of corrosion-resistant polyether sponge, and the lubricating oil can be absorbed by the oil-absorbing block c1.

[0037] Wherein, the air-drying mechanism c3 includes a rebound bar c31, an exhaust chamber c32, a swing plate c33, and an outer ring c34....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com