External conductive cable connector

A conductive cable, external technology, applied in the direction of conductive connection, electrical component connection, connection, etc., can solve the problems of inconvenient use, increase redundant processes, etc., and achieve the effect of speeding up the work progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

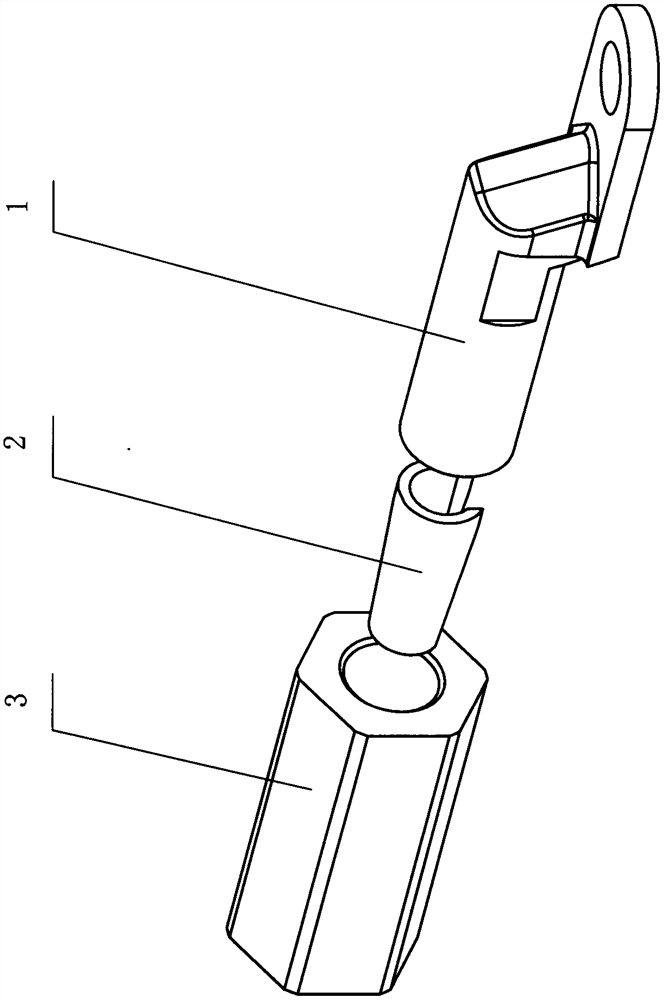

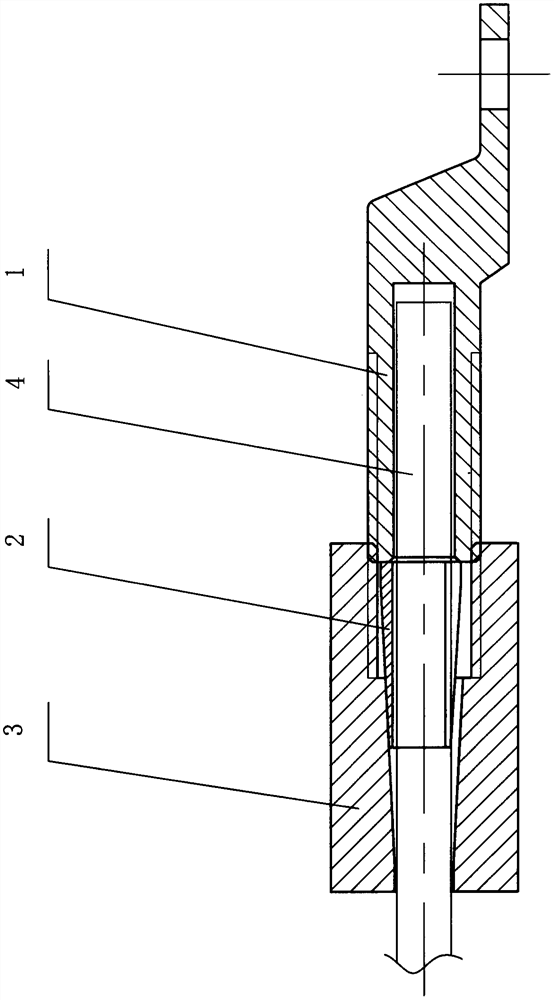

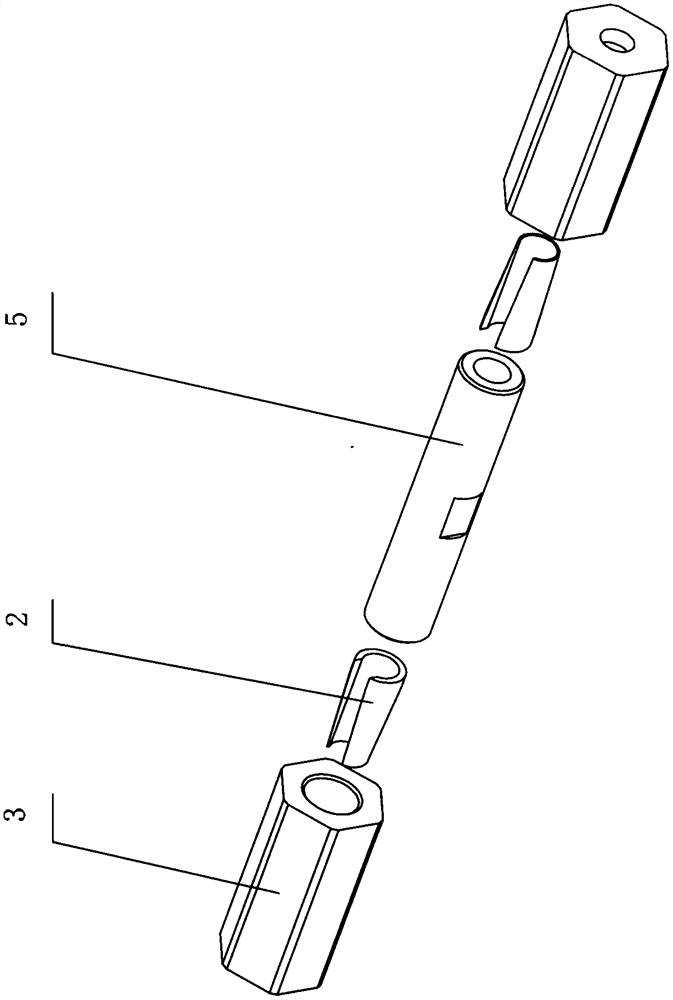

[0040] The second embodiment of the external conductive cable connector of the present invention is:

[0041] The external conductive cable connector includes a conductive wiring sleeve 5, two clamping parts and two locking screw sleeves 3, and the left and right ends of the conductive wiring sleeve 5 are provided with external threads; each clamping piece It is a conductive tapered shrink sleeve 2 with an axial contraction groove, and the thickness of the large cone head end of each conductive tapered shrink sleeve 2 is greater than the thickness of the small cone head end; the sleeve holes of each locking screw sleeve 3 are coaxial internal threads Holes and taper holes, the internally threaded hole of the locking nut 3 matches the external thread on the head of the conductive wire sleeve 5 and the length of the internally threaded hole is shorter than the length of the external thread, the large hole end of the tapered hole communicates with the internally threaded hole and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com