Size-customizable naturally aspirated combustion-supporting high-efficiency gas kitchen stove and manufacturing method thereof

A technology of natural suction and size, applied in the mechanical field, can solve the problems of insufficient space utilization, small heating area, gas waste, etc., to achieve the effect of convenient and fast welding method, increase the heat absorption area, and the welding seam is not easy to leak.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

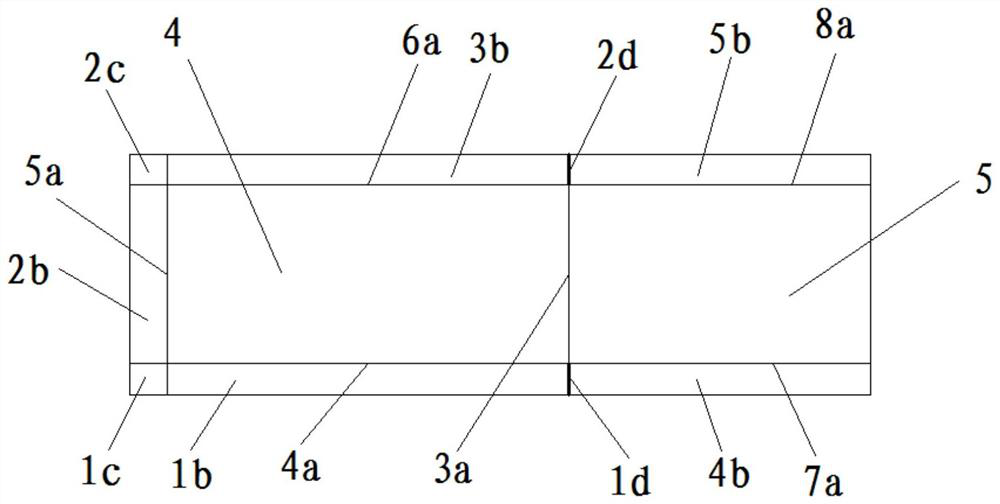

[0117] A naturally aspirated combustion-supporting and high-efficiency gas kitchen stove with customizable size, comprising a stove frame 13, a pot liner 10, a combustion chamber 11, a smoke exhaust pipe 12 and a gas combustion head, the pot liner 10 is fixed on the stove frame 13, and the pot 10 is fixed on the stove frame 13. The bottom of the bladder 10 is a combustion chamber 11, the bottom surface 7 of the combustion chamber is provided with a gas combustion head installation port 9, the gas combustion head is fixed in the combustion chamber 11, the lower end of the smoke exhaust pipe 12 is communicated with the combustion chamber 11, and the bottom surface 4 of the pot is fixed with a plurality of Heat transfer pins 17.

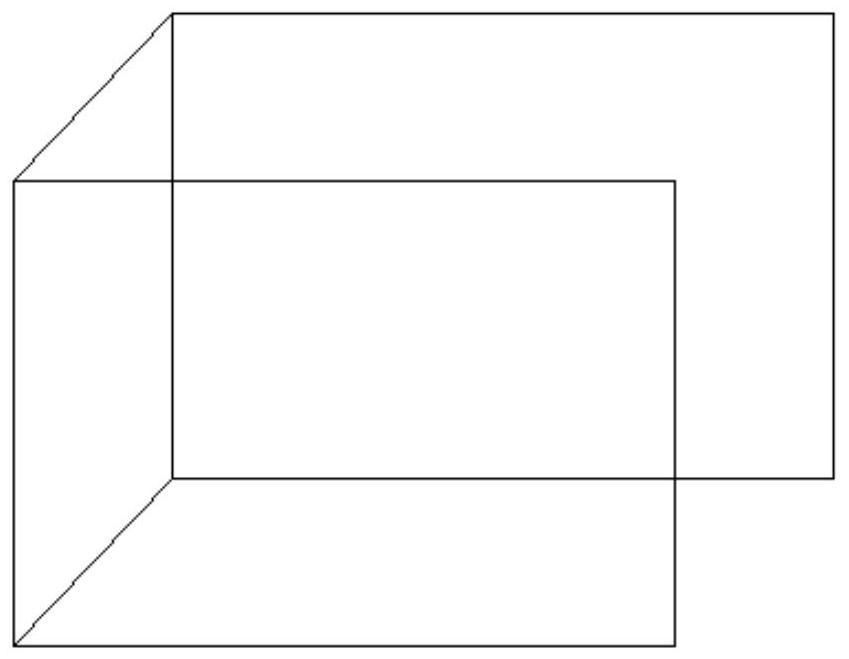

[0118] The inner pot 10 includes a first component and a second component,

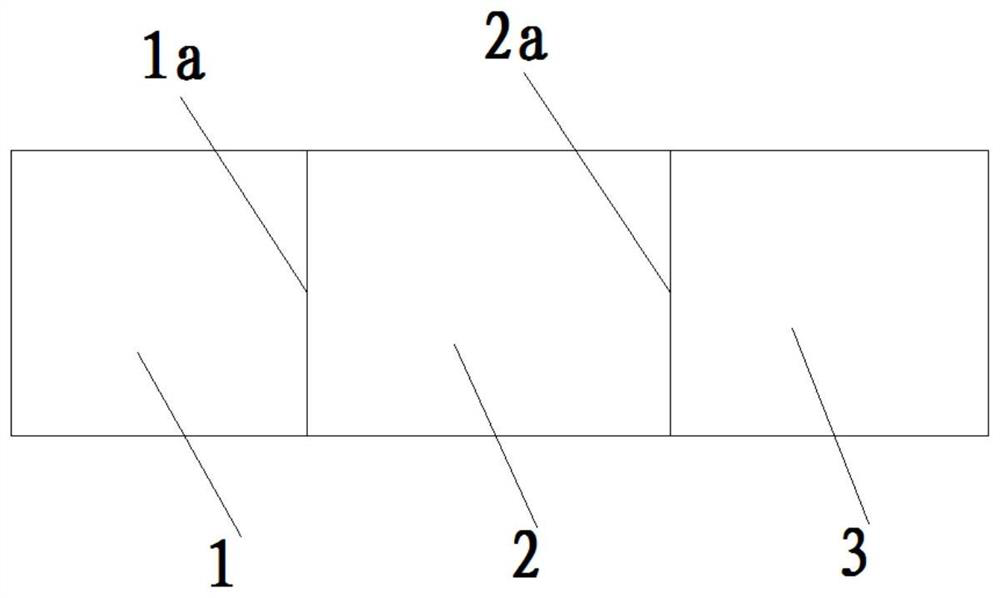

[0119] Component 1 is a U-shaped piece, the U-shaped piece is an integral plate, and the three faces of the U-shaped piece are the front of the pot 1, the left side of the pot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com