A kind of mass concrete temperature control method

A technology of mass concrete and temperature control method, which is applied in the processing of building materials, construction, infrastructure engineering, etc., can solve the problems of time-consuming and laborious control process, poor control accuracy, etc., to improve cooling efficiency, reduce temperature difference, and ensure water flow. smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

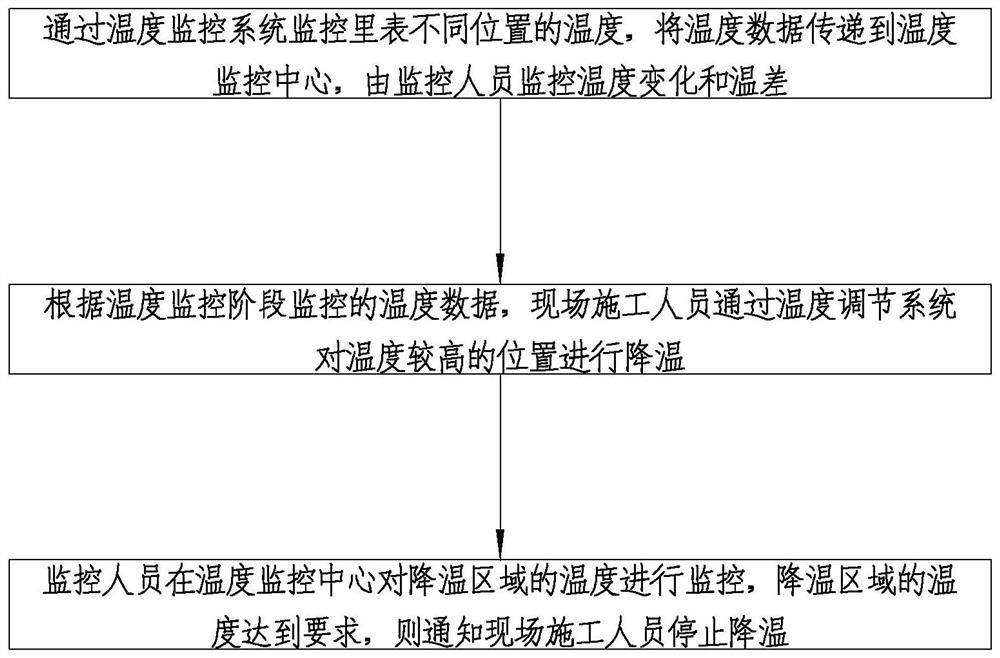

[0036] Attached to the following Figure 1-2 This application will be described in further detail.

[0037] The embodiment of the present application discloses a method for controlling the temperature of mass concrete, refer to figure 1 and 2 , including a temperature monitoring stage, a temperature adjustment stage and an adjustment feedback stage, and the temperature changes inside and outside the mass concrete 100 are controlled through process control.

[0038] For the convenience of description, in this embodiment, the mass concrete 100 is set as a cuboid structure, and anti-crack fibers are mixed in the concrete for pouring the mass concrete 100. The anti-crack fibers have good dispersibility and good water-holding effect, and can effectively cover the mortar. , Concrete surface, can protect the optical fiber, and at the same time has good tensile strength, has a strong tensile adhesion effect, and plays the role of crack resistance and anti-seepage.

[0039]Specifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com