A preparation method of heat-not-burn cigarette paper containing boron nitride thermally conductive filler

A heat-not-burn, cigarette paper technology, applied in special paper, inorganic compound addition, papermaking, etc., can solve the problems of unfavorable release of nicotine and aromatic substances in the cigarette core, low thermal conductivity, affecting the taste of cigarettes, etc., and achieve low cost. , High thermal conductivity, the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

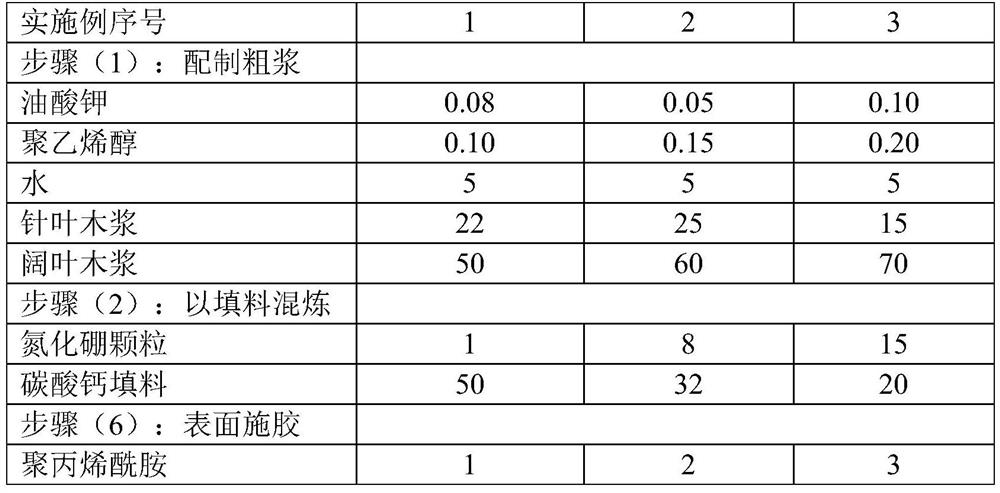

[0027] Below in conjunction with specific embodiment and comparative example the invention is described in further detail. The examples can enable those skilled in the art to understand the present invention more comprehensively, but do not limit the present invention in any way.

[0028] A method for preparing a heat-not-burn cigarette paper containing a boron nitride thermally conductive filler, comprising the following steps:

[0029] (1) Preparation of coarse pulp

[0030] Mix 0.05-0.1 parts by weight of potassium oleate, 0.1-0.2 parts by weight of polyvinyl alcohol and 5 parts by weight of water, stir evenly under ultrasonic conditions for 30 minutes, age for 2 hours and filter until there is no precipitation; mix the obtained mixed solution with 15-25 parts by weight 50-70 parts by weight of softwood pulp and 50-70 parts by weight of hardwood pulp are uniformly mixed to obtain coarse pulp.

[0031] (2) Mixing with filler

[0032] Under stirring conditions, 1-15 parts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com