A functionalized core-shell nanowire and its preparation method and application

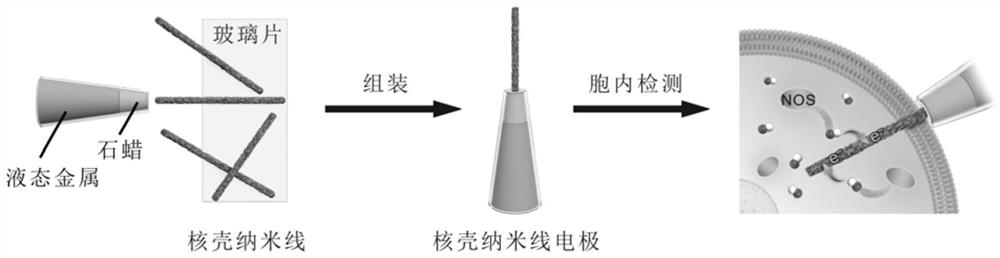

A core-shell nano-functionalization technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for sensing, etc., can solve the problems of tedious and time-consuming preparation process, limited material types, etc., and achieve simplified preparation process and wide application Prospects, Effects of Excellent Electrochemical Performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

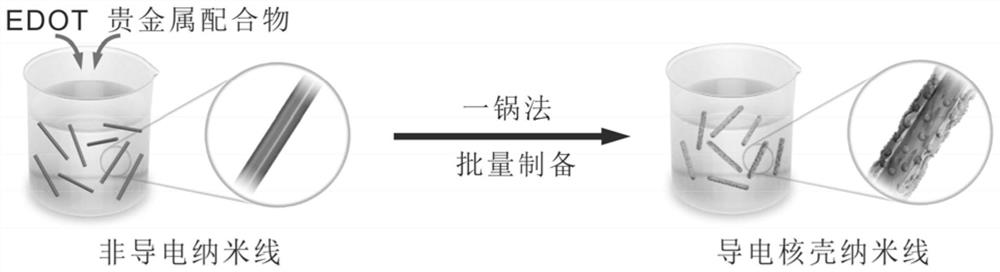

Method used

Image

Examples

Embodiment 1

[0034] The specific preparation steps of SiC@Au-PEDOT nanowires (SiC as the core and Au-PEDOT as the shell) are as follows:

[0035] (1) Put 1 mg of SiC nanowires in a 100 mL beaker, add 30 mL of acetonitrile as a solvent, and ultrasonically disperse the SiC nanowires evenly.

[0036] (2) Under stirring, add 500 μL of EDOT monomer to the SiC dispersion liquid obtained in step (1), so that EDOT is uniformly dispersed and dissolved.

[0037] (3) Add 2 mL of HAuCl to the dispersion obtained in step (2) 4 (25mM) as an oxidizing agent to initiate chemical polymerization. In this process, EDOT is oxidatively polymerized into the conductive polymer PEDOT, AuCl 4 - Reduction to gold nanoparticles.

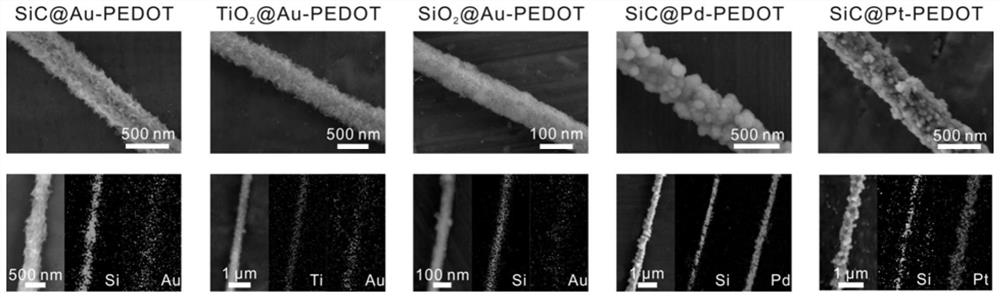

[0038] (4) After the reaction system was stirred at room temperature for 24 h, the reaction solution was centrifuged and washed three times with water and ethanol respectively to obtain SiC@Au-PEDOT core-shell nanowires. like figure 2 As shown, the surface of SiC@Au-PEDOT nanowires ...

Embodiment 2

[0040] TiO 2 @Au-PEDOT nanowires (TiO 2 is the core, and Au-PEDOT is the shell) the specific preparation steps are as follows:

[0041] (1) 1mg TiO 2 Nanowires were placed in a 100mL beaker, 30mL of acetonitrile was added as a solvent, and the TiO 2 The nanowires are uniformly dispersed.

[0042] (2) under stirring state, to the TiO obtained in step (1) 2 Add 500μL EDOT monomer to the dispersion liquid to make EDOT evenly dispersed and dissolved.

[0043] (3) Add 2 mL of HAuCl to the dispersion obtained in step (2) 4 (25mM) as an oxidizing agent to initiate chemical polymerization. In this process, EDOT is oxidatively polymerized into the conductive polymer PEDOT, AuCl 4 - Reduction to gold nanoparticles.

[0044] (4) After the reaction system was stirred at room temperature for 24 hours, the reaction solution was centrifuged, and washed 3 times with water and ethanol respectively to obtain TiO 2 @Au-PEDOT core-shell nanowires. like figure 2 Shown, TiO 2 The surf...

Embodiment 3

[0046] SiO 2 @Au-PEDOT nanowires (SiO 2 is the core, and Au-PEDOT is the shell) the specific preparation steps are as follows:

[0047] (1) 1mg SiO 2 Nanowires were placed in a 100mL beaker, 30mL of acetonitrile was added as a solvent, and the TiO 2 The nanowires are uniformly dispersed.

[0048](2) under stirring state, to the SiO that step (1) obtains 2 Add 500μL EDOT monomer to the dispersion liquid to make EDOT evenly dispersed and dissolved.

[0049] (3) Add 2 mL of HAuCl to the dispersion obtained in step (2) 4 (25mM) as an oxidizing agent to initiate chemical polymerization. In this process, EDOT is oxidatively polymerized into the conductive polymer PEDOT, AuCl 4 - Reduction to gold nanoparticles.

[0050] (4) After the reaction system was stirred at room temperature for 24 hours, the reaction solution was centrifuged, and washed 3 times with water and ethanol respectively to obtain SiO 2 @Au-PEDOT core-shell nanowires. like figure 2 Shown, SiO 2 The surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com