Magnet component, magnetron sputtering cathode and magnetron sputtering device for flexible wire coating

A technology of magnetron sputtering device and magnet components, which is applied in the direction of sputtering coating, ion implantation coating, vacuum evaporation coating, etc., can solve the problems without too much explanation, achieve improvement effect, increase utilization rate, uniform The effect of coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

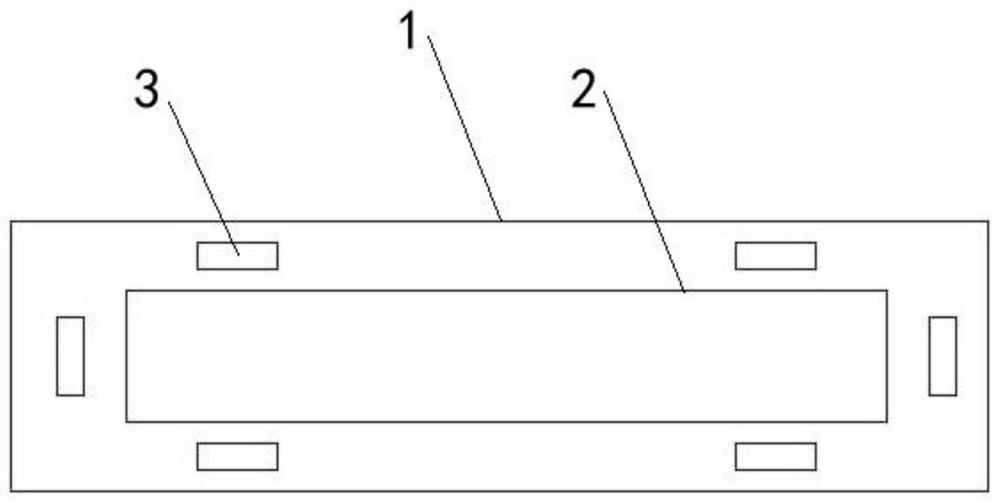

[0032] Such as figure 1 Shown: a magnet component, including an outer magnet 1 , an inner magnet 2 and six auxiliary magnets 3 . Both the outer magnet 1 and the inner magnet 2 have a rectangular ring structure, the inner magnet 2 is located inside the outer magnet 1 and the installation polarity of the two is opposite, and six auxiliary magnets 3 are arranged in the annular gap between the outer magnet 1 and the inner magnet 2, The outer magnet 1 and the inner magnet 2 are permanent magnets, and the auxiliary magnet 3 is an electromagnet. Wherein, the outer magnet 1 and the inner magnet 2 constitute the main magnetic field of the magnet component, and since the outer magnet 1 and the inner magnet 2 are permanent magnets, the main magnetic field is a stable magnetic field. The addition of the auxiliary magnet 3 can generate an auxiliary magnetic field, which can interfere with the main magnetic field and change the magnetic field environment of the magnet components. The auxi...

Embodiment 2

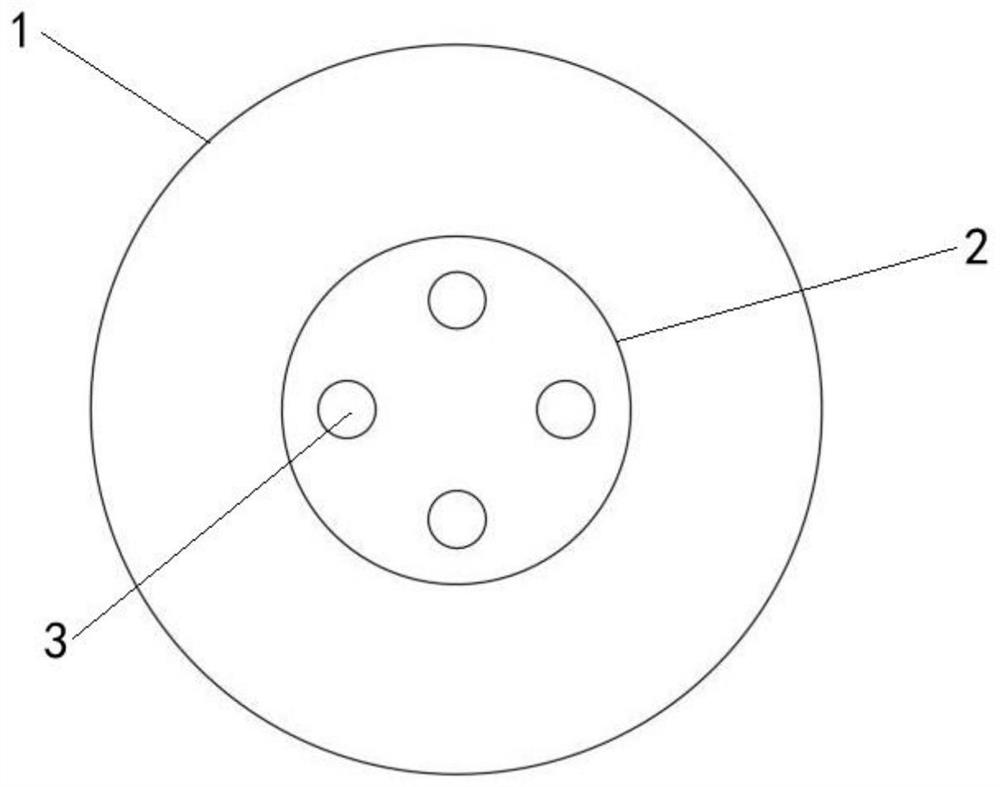

[0034] Such as figure 2 Shown: a magnet component, including an outer magnet 1 , an inner magnet 2 and four auxiliary magnets 3 . Both the outer magnet 1 and the inner magnet 2 are circular structures, the inner magnet 2 is located inside the outer magnet 1 and the installation polarity of the two is opposite, two auxiliary magnets 3 are arranged inside the inner magnet 2, the outer magnet 1 and the inner magnet 2 It is a permanent magnet, and the auxiliary magnet 3 is an electromagnet. Wherein, the outer magnet 1 and the inner magnet 2 constitute the main magnetic field of the magnet component, and since the outer magnet 1 and the inner magnet 2 are permanent magnets, the main magnetic field is a stable magnetic field. The addition of the auxiliary magnet 3 can generate an auxiliary magnetic field, which can interfere with the main magnetic field and change the magnetic field environment of the magnet components. The auxiliary magnet 3 is made of an iron core and a coil wo...

Embodiment 3

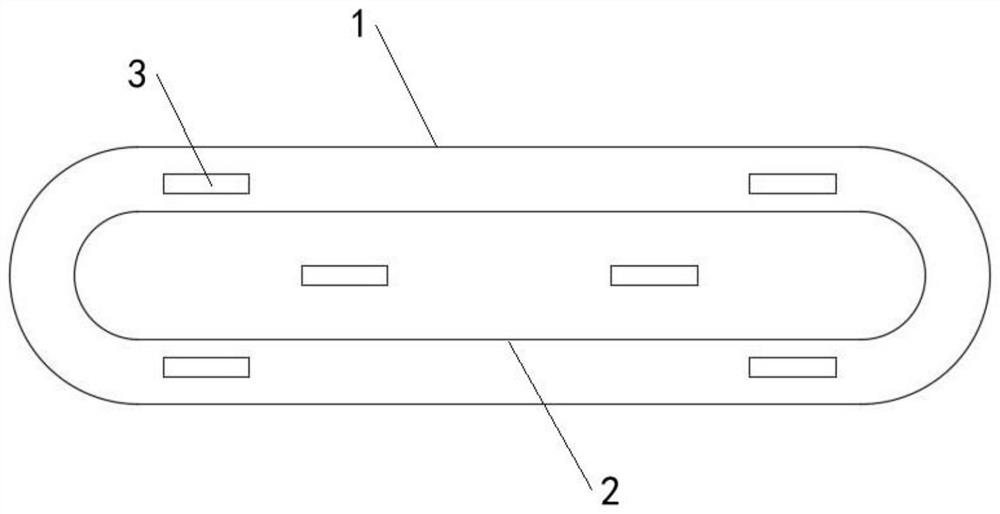

[0036]Such as image 3 Shown: a magnet component, including an outer magnet 1 , an inner magnet 2 and six auxiliary magnets 3 . The outer magnet 1 and the inner magnet 2 are both racetrack-shaped structures, the inner magnet 2 is located inside the outer magnet 1 and the installation polarities of the two are opposite, of which 2 auxiliary magnets 3 are arranged inside the inner magnet 2, and the remaining 4 auxiliary magnets 3 are arranged In the annular gap between the outer magnet 1 and the inner magnet 2, the outer magnet 1 and the inner magnet 2 are permanent magnets, and the auxiliary magnet 3 is an electromagnet. The upper surfaces of the outer magnet 1 and the inner magnet 2 are curved surfaces, which are suitable for the curvature of the water-cooled back plate 6 . Wherein, the outer magnet 1 and the inner magnet 2 constitute the main magnetic field of the magnet component, and since the outer magnet 1 and the inner magnet 2 are permanent magnets, the main magnetic f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com