Air cooling device for cutting pick manufacturing

An air-cooling device and air-cooling technology, applied in the direction of manufacturing tools, heat treatment process control, furnaces, etc., can solve problems such as difficult to accurately control cooling speed, cooling speed change, small pick size, etc., to achieve precise control and precise heat dissipation speed , The effect of expanding the heat dissipation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

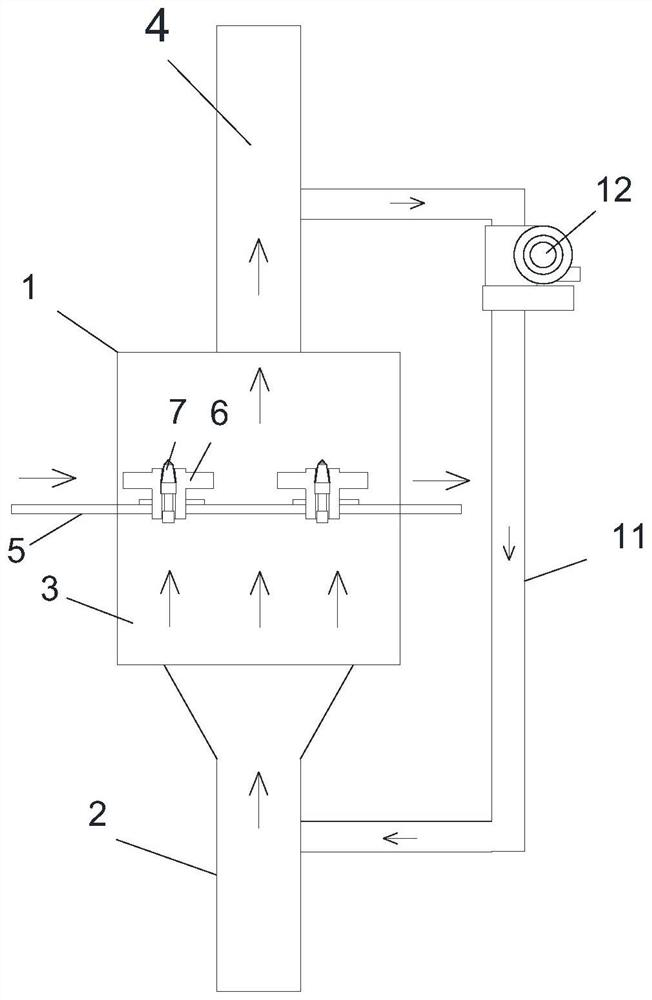

[0040] The technical solutions of the present invention will be better understood by those skilled in the art, and the invention will be further described in conjunction with the accompanying drawings.

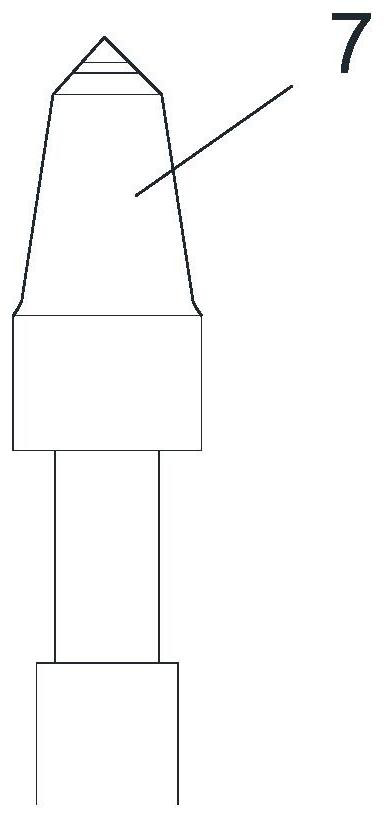

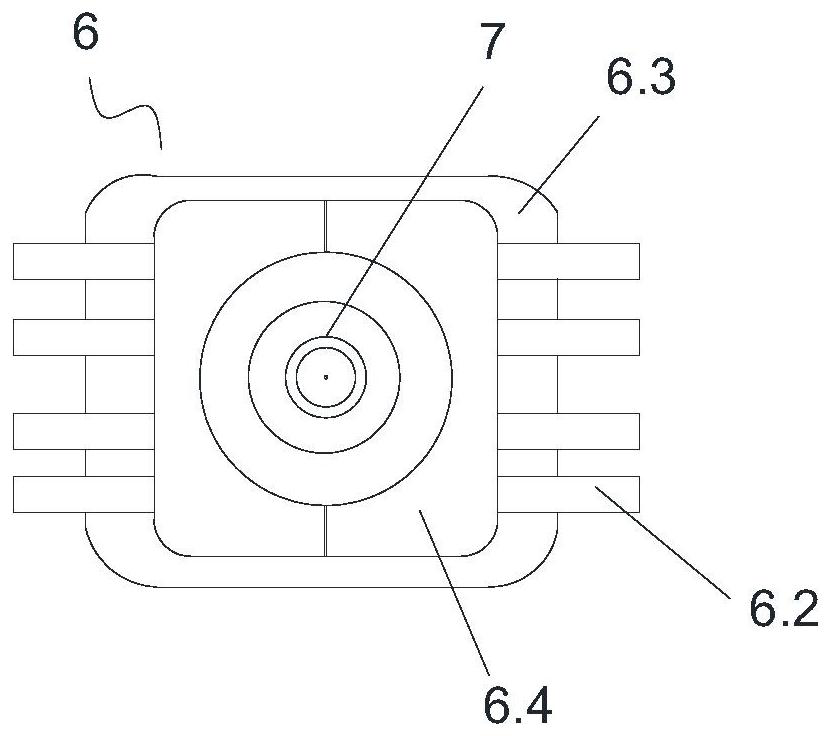

[0041] like Figure 1-8 As shown, the embodiment of the present invention provides a air-cooling device for truncation 7, comprising a housing 1, and an intake passage 2, a ventilation passage 2, a wind-cooled chamber 3, and an exhaust gas within the housing 1 are provided. Channel 4, the wind cooling chamber 3 is provided with a feed mechanism 5, and a plurality of equalization heat dissipation members 6 are provided on the feeding mechanism 5, and the equalization heat dissipation member 6 includes a receiving cavity 6.1 for carrying the truncation 7. The outer shape of the receiving chamber 6.1 is consistent with the outer profile of the truncation 7; a heat dissipating fin 6.2 is provided on the equalization heat dissipation member 6.

[0042] Specifically, the air-cooling devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com