Preparation method of active packaging film using cellulose for controlled release

A packaging film and cellulose technology, which is applied in the field of active packaging film preparation, can solve problems such as food safety issues, and achieve the effects of improving comprehensive performance, enhancing mechanical properties and hydrophobicity, and protecting food.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following describes the implementation of the present invention in detail by taking specific embodiments as examples in conjunction with the accompanying drawings.

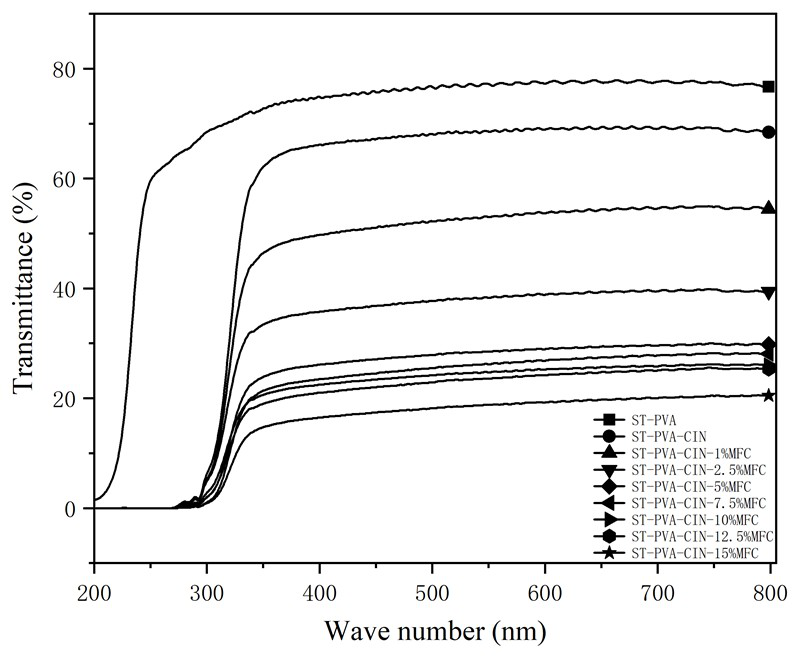

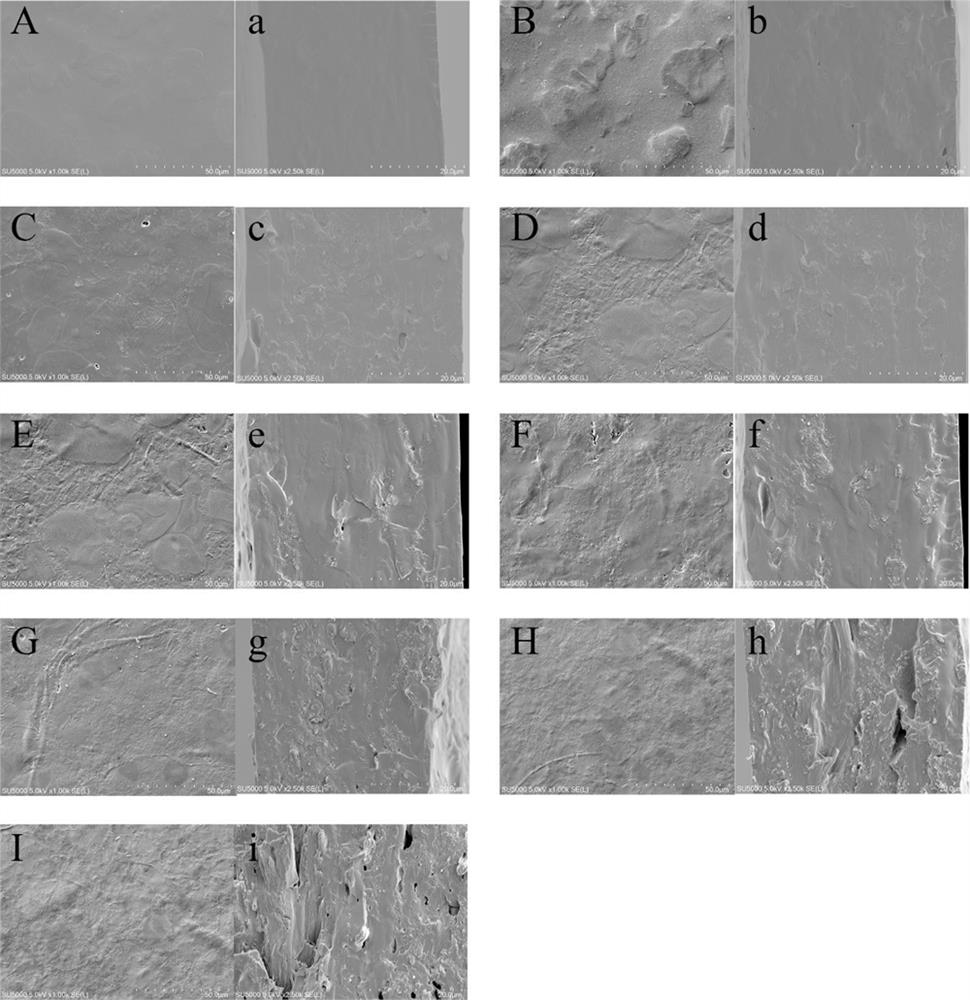

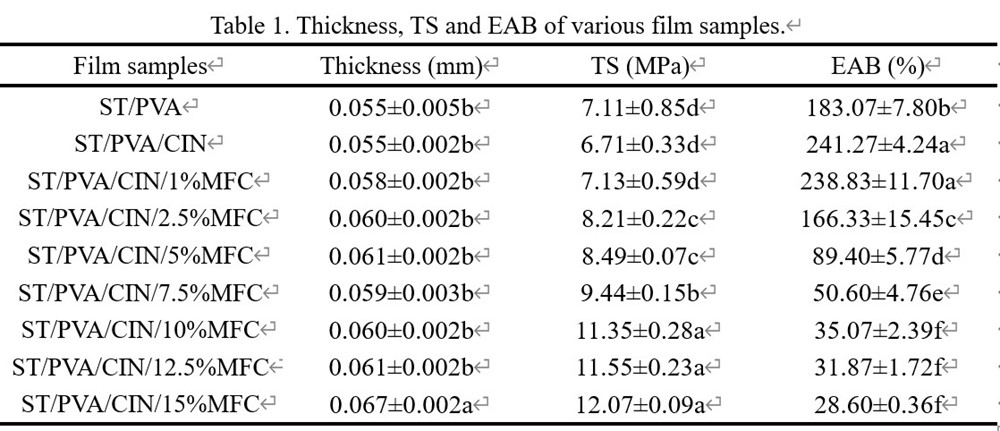

[0023] Film preparation: Polyvinyl alcohol (polyvinyl alcohol)-cornstarch (cornstarch) film was prepared by solution casting method. Pure starch / polyvinyl alcohol film: Weigh 4g of polyvinyl alcohol into 50g of water, and keep stirring in a 97°C water bath for 1 hour until it is completely dissolved. Weigh 4g of cornstarch into 50g of water, stir at 97°C for 30min, slowly pour the polyvinyl alcohol solution into the starch solution, add 1.2mL of glycerin, 1.2g of citric acid, stir for 20min, take it out and ultrasonically defoam for 30min , Cast film at 60°C. Preparation of active film containing cinnamaldehyde: weigh 4 g of polyvinyl alcohol, microfibrillated cellulose (0%, 1%, 2.5%, 5%, 7.5%, 10%, 12.5%, 15% w / w) in 50 g In water, keep stirring in a 95°C water bath for 1 hour until completely dissol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com