Fluorine-containing epoxy resin curing agent and preparation method thereof

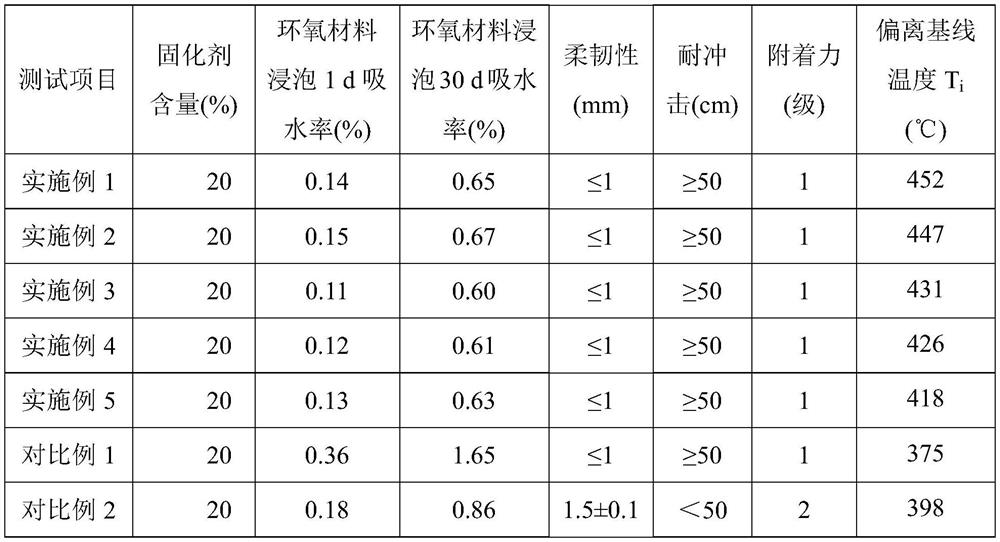

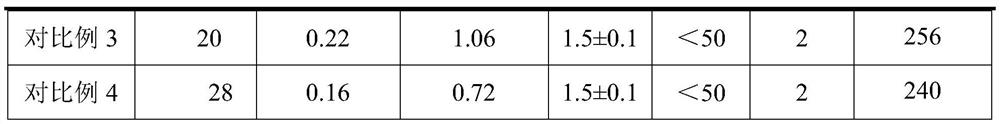

A technology of epoxy resin curing and end-capping agent, which is applied in the field of curing agent and can solve problems such as poor thermal stability, poor water resistance, and poor flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for preparing a fluorine-containing epoxy resin curing agent, comprising the following steps: adding a modifier and an amine compound to dimethyl sulfoxide, under nitrogen protection, and reacting in the dark at 40°C for 20 hours , Distilled under reduced pressure, then added to ethanol solution, at 50°C, slowly added end-capping agent, reacted for 4h, distilled under normal pressure to obtain fluorine-containing epoxy resin curing agent.

[0026]Furthermore, the modifying agent is 2,2,3,3,4,4-hexafluoro-1,5-dimethacrylate pentyl ester.

[0027] Further, the amine compounds include 1,3-bis(3-aminopropyl)-1,1,3,3-tetramethyldisiloxane, octaaminopropyl clathrate polysilsesquioxane Alkane and 2-(tetrazol-5-yl)phenylboronic acid modified 3-aminopropyldimethylmethoxysilane are compounded according to the mass ratio of 65:5:30.

[0028] Further, the preparation method of the 2-(tetrazol-5-yl) phenylboronic acid modified 3-aminopropyl dimethyl methoxysilane comprises...

Embodiment 2

[0036] A method for preparing a fluorine-containing epoxy resin curing agent, characterized in that it comprises the following steps: adding a modifier and an amine compound to dimethyl sulfoxide, under nitrogen protection, and reacting in the dark at 45°C for 22 hours , Distilled under reduced pressure, and then added to ethanol solution, under the condition of 55°C, slowly added end-capping agent, reacted for 4.5h, and distilled under normal pressure to obtain a fluorine-containing epoxy resin curing agent.

[0037] Furthermore, the modifying agent is 2,2,3,3,4,4-hexafluoro-1,5-diacrylate pentyl ester.

[0038] Further, the amine compounds include 1,3-bis(3-aminopropyl)-1,1,3,3-tetramethyldisiloxane, octaaminopropyl clathrate polysilsesquioxane Alkane and 2-(tetrazol-5-yl)phenylboronic acid modified 3-aminopropyldimethylmethoxysilane are compounded according to the mass ratio of 68:4.5:27.5.

[0039] Further, the preparation method of the 2-(tetrazol-5-yl) phenylboronic aci...

Embodiment 3

[0047] A method for preparing a fluorine-containing epoxy resin curing agent, comprising the following steps: adding a modifier and an amine compound to dimethyl sulfoxide, under nitrogen protection, and reacting in the dark at 50°C for 24 hours , Distilled under reduced pressure, then added to ethanol solution, at 60°C, slowly added end-capping agent, reacted for 5 hours, and distilled under normal pressure to obtain a fluorine-containing epoxy resin curing agent.

[0048] Furthermore, the modifying agent is 2,2,3,3,4,4,5,5-octafluoro-1,6-dimethacrylate hexyl ester.

[0049] Further, the amine compounds include 1,3-bis(3-aminopropyl)-1,1,3,3-tetramethyldisiloxane, octaaminopropyl clathrate polysilsesquioxane Alkane and 2-(tetrazol-5-yl)phenylboronic acid modified 3-aminopropyldimethylmethoxysilane are compounded according to the mass ratio of 70:4:26.

[0050] Further, the preparation method of the 2-(tetrazol-5-yl) phenylboronic acid modified 3-aminopropyl dimethyl methoxys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shock proof | aaaaa | aaaaa |

| Water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com