Multi-stage membrane concentration oily wastewater device

A membrane concentration and waste water technology, applied in the field of petrochemical industry, can solve the problems of water resource pollution, waste of petroleum resources, etc., and achieve the effect of increasing membrane flux and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

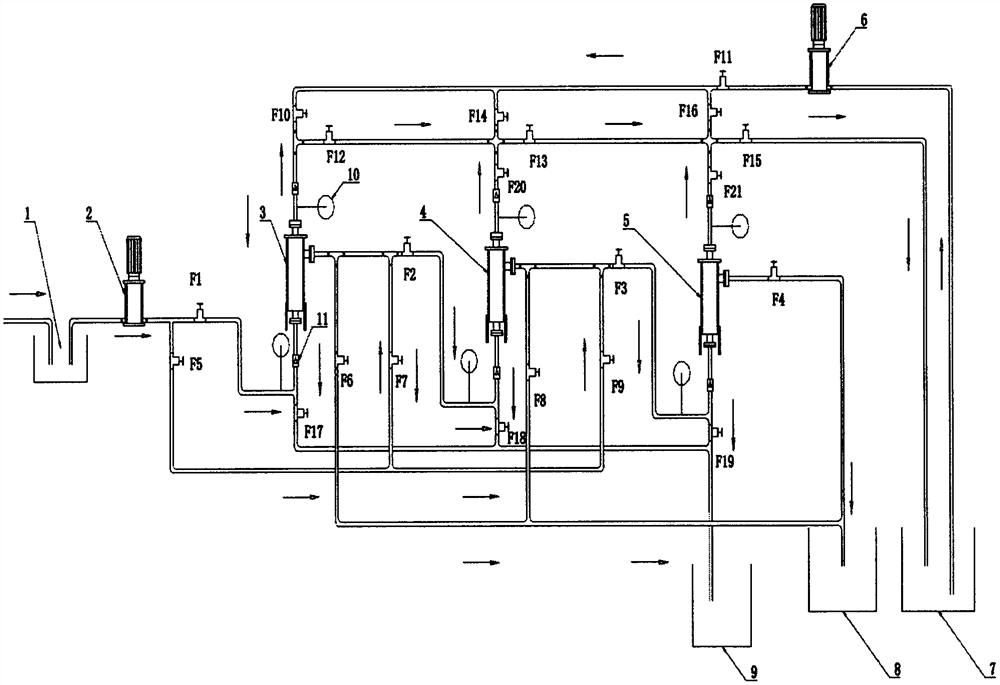

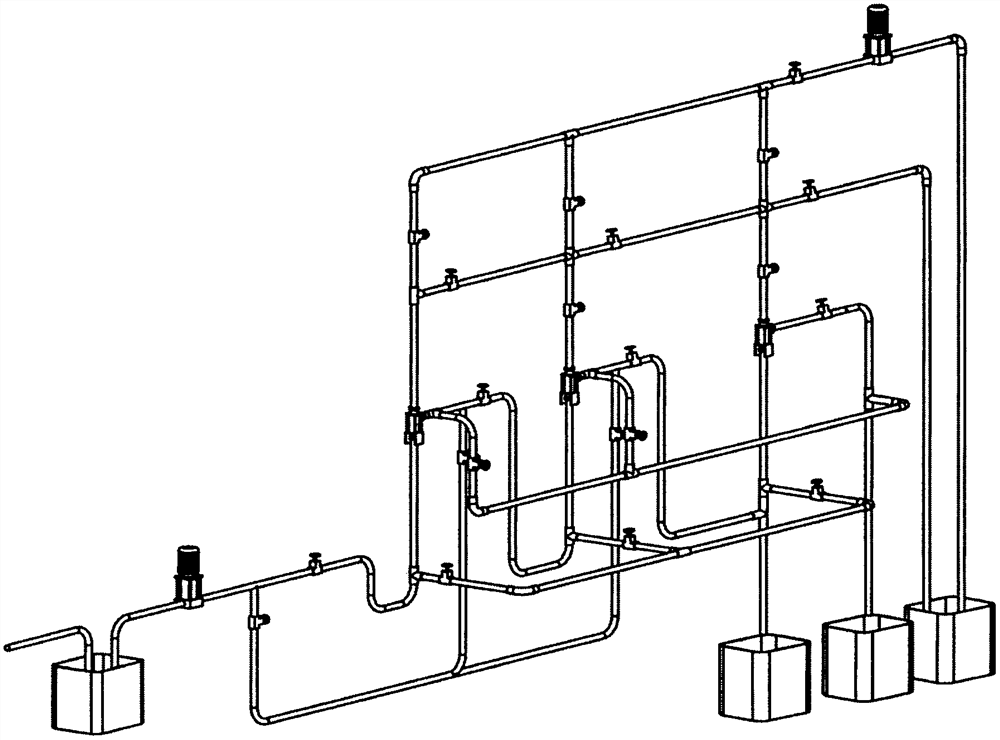

[0022] The multi-stage membrane concentrated oil wastewater apparatus, working principle and procedure are described below: Oil wastewater enters (1) in the sewage water pipe, precipitate some of the heavier substances in the oil-containing wastewater, and then pass (2) Pressure pump extraction (1) The supernatant in the precipitated tank. The operation steps of the nanofiltration system are as follows: Open the valves F1, F6, F12, F13, F15, the remaining valves are closed, the supernatant passes through the valve F1 into (3) nanofiltration membrane, removes a large amount of water and low-priced molecular solute , The oil in the supernatant, (10) pressure gauge measuring (3) nanofiltration membrane outlet pressure and inlet pressure, (11) flow meter measurement (3) The inlet flow rate and outlet flow of nanofiltration membranes, obtained after treatment The concentrate passes through the pipe F6 into (8) concentrated liquid storage pool, and the permeate passes through the valve ...

Embodiment 2

[0024] Nonofiltration - Ultrafiltration System The operation steps are as follows: Open the valves F1, F2, F8, F12, F13, F15, F20, the remaining valves close, the supernatant passes through the pipe through the valve F1 into (3) nanofiltration membrane, remove a large amount of water As well as low-priced small molecular solutes, concentrated oils, (10) pressure gauge measuring (3) nation filter outlet pressure and import pressure, (11) flow meter measurement (3) Nate the imported flow and outlet of nation filter Flow, the concentrate obtained after treatment enters (4) ultrafiltration membranes via the valve F2, and the permeation liquid enters (7) osmotic storage pool through valve F12, F13, F15. The concentrate was removed by (4) ultrafiltration membrane to remove water and a small amount of small molecular material, further concentrating the oil in the concentrate, (10) pressure gauge measuring (4) ultrafiltration membrane outlet pressure and import pressure, (11) flow Measure...

Embodiment 3

[0026]Nonofiltration-microfiltration system operation steps are as follows: Open the valves F1, F7, F9, F3, F4, F12, F13, F21, F15, and the remaining valves are closed, the supernatant passes (3) nanofiltration membranes via the valve F1 through the pipe. Remove large amounts of water and low-cost small molecular solute, concentrate oil in the supernatant, (10) pressure gauge measuring (3) Nate filter outlet pressure and inlet pressure, (11) flow meter measurement (3) nanofiltration membrane Inlet flow and export flow, the concentrate obtained after treatment passes through the valve F7, F9, F3 into (5) microfiltration membranes, and the permeation liquid is entered (7) osmotic storage pool through valve F12, F13, F15. The concentrate was removed by (5) microfiltration membrane removal of water, a small amount of small molecule solute and macromolecular solute, further concentrating the oil in the concentrate, (10) pressure gauge measuring (5) microfiltration membrane outlet press...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com