Method and system for removing vanadium from crude titanium tetrachloride

A technology of crude titanium tetrachloride and organic matter, which is applied in the chemical industry, can solve the problems that affect the continuous and stable operation of the refining system, and the superheater is easy to foul, so as to avoid the formation of fouling, reduce cleaning operations, and ensure stable operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

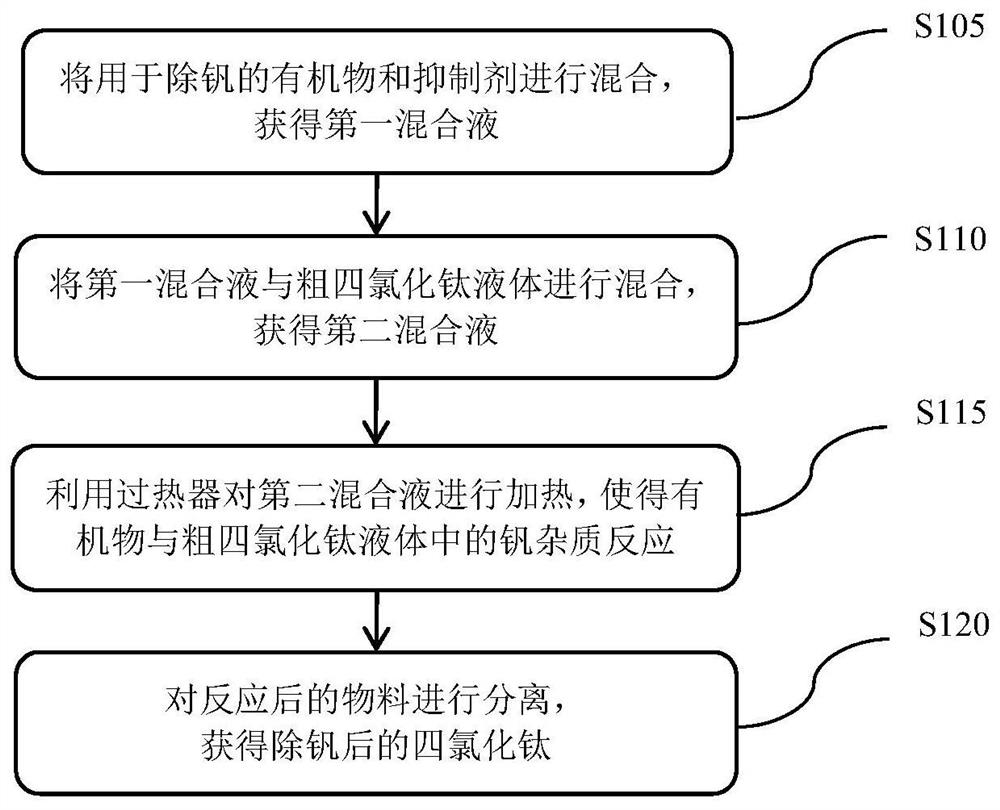

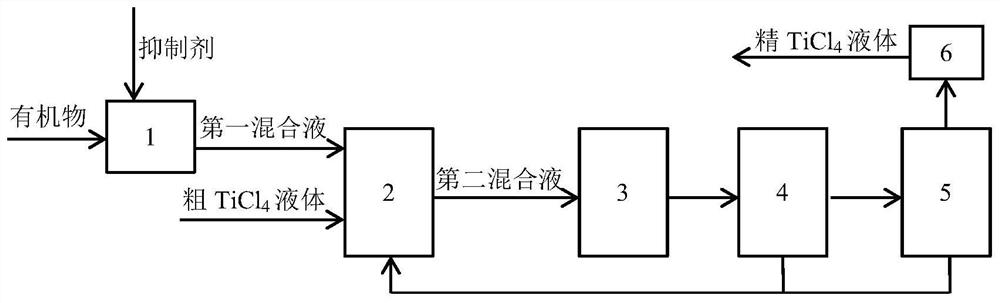

[0044] A method for removing vanadium, comprising the steps of:

[0045] Add fatty acid and polymerization inhibitor PI-70 in mixing tank, control the consumption ratio of polymerization inhibitor PI-70 and fatty acid to be 10g:1L, fully stir it and make it mix uniformly, obtain the first mixed solution;

[0046] Afterwards, in the first mixed solution input circulation tank by pump, control its feed rate to be 60kg / h, add thick titanium tetrachloride liquid in the circulation tank simultaneously, control its feed rate to be 8000kg / h, to The two are mixed to obtain a second mixed solution;

[0047] Afterwards, the second mixed liquid is pumped into the superheater for heat treatment, and the outlet temperature of the tube side of the superheater is controlled to be 155° C., and the pressure is 0.35 MPa, so that the organic matter and the vanadium in the crude titanium tetrachloride liquid Impurities are reacted to obtain a mixture containing vanadium-removed mud;

[0048] Af...

Embodiment 2

[0051] A method for removing vanadium, comprising the steps of:

[0052] Add fatty acid and polymerization inhibitor PI-70 in mixing tank, control the consumption ratio of polymerization inhibitor PI-70 and fatty acid to be 20g:1L, fully stir it and make it mix uniformly, obtain the first mixed liquor;

[0053] Afterwards, in the first mixed solution input circulation tank by pump, control its feed rate to be 60kg / h, add thick titanium tetrachloride liquid in the circulation tank simultaneously, control its feed rate to be 8000kg / h, to The two are mixed to obtain a second mixed solution;

[0054] Afterwards, the second mixed liquid is pumped into the superheater for heat treatment, and the outlet temperature of the tube side of the superheater is controlled to be 155° C., and the pressure is 0.35 MPa, so that the organic matter and the vanadium in the crude titanium tetrachloride liquid Impurities are reacted to obtain a mixture containing vanadium-removed mud;

[0055] Afte...

Embodiment 3

[0058] A method for removing vanadium, comprising the steps of:

[0059] Add fatty acid and triphenyl phosphite in mixing tank, control the consumption ratio of triphenyl phosphite and fatty acid to be 40g:1L, fully stir it and make it mix evenly, obtain the first mixed solution;

[0060] Afterwards, in the first mixed solution input circulation tank by pump, control its feed rate to be 60kg / h, add thick titanium tetrachloride liquid in the circulation tank simultaneously, control its feed rate to be 8000kg / h, to The two are mixed to obtain a second mixed solution;

[0061] Afterwards, the second mixed liquid is pumped into the superheater for heat treatment, and the outlet temperature of the tube side of the superheater is controlled to be 160° C., and the pressure is 0.32 MPa, so that the organic matter and the vanadium in the crude titanium tetrachloride liquid Impurities are reacted to obtain a mixture containing vanadium-removed mud;

[0062] Afterwards, spray the mixtu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com