Cotton mold film removing machine

A film machine and film cutting technology, which is applied in the directions of packaging, cutting and unsealing, transportation and packaging, etc., can solve the problems of difficult film cutting, low efficiency and heavy weight for workers, and achieve the effect of improving operation safety and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

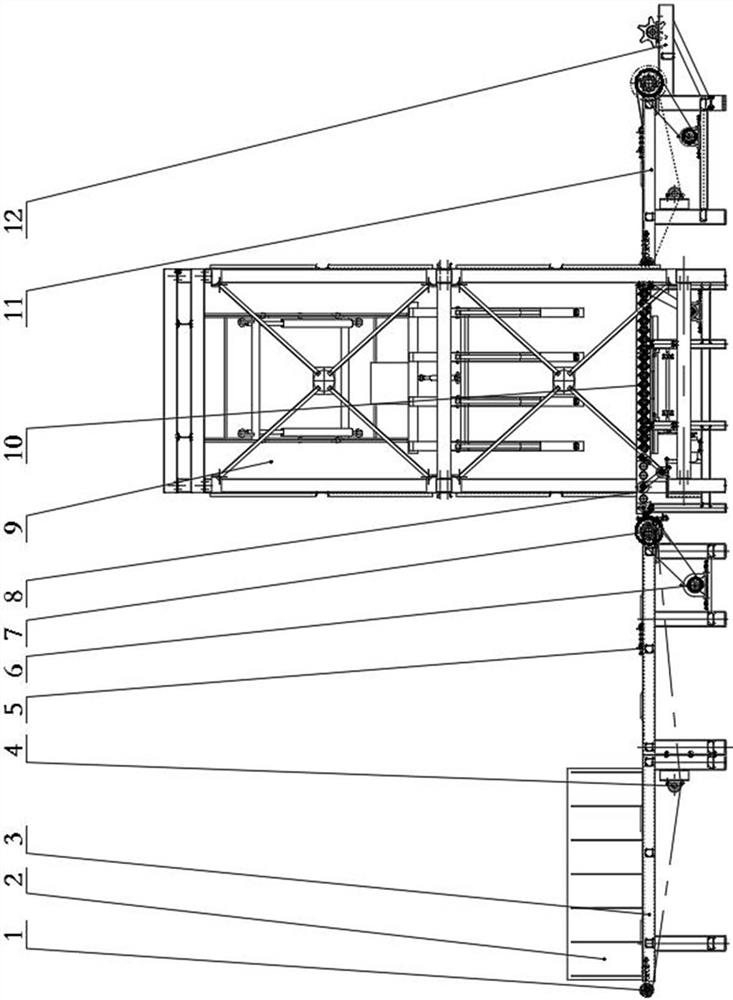

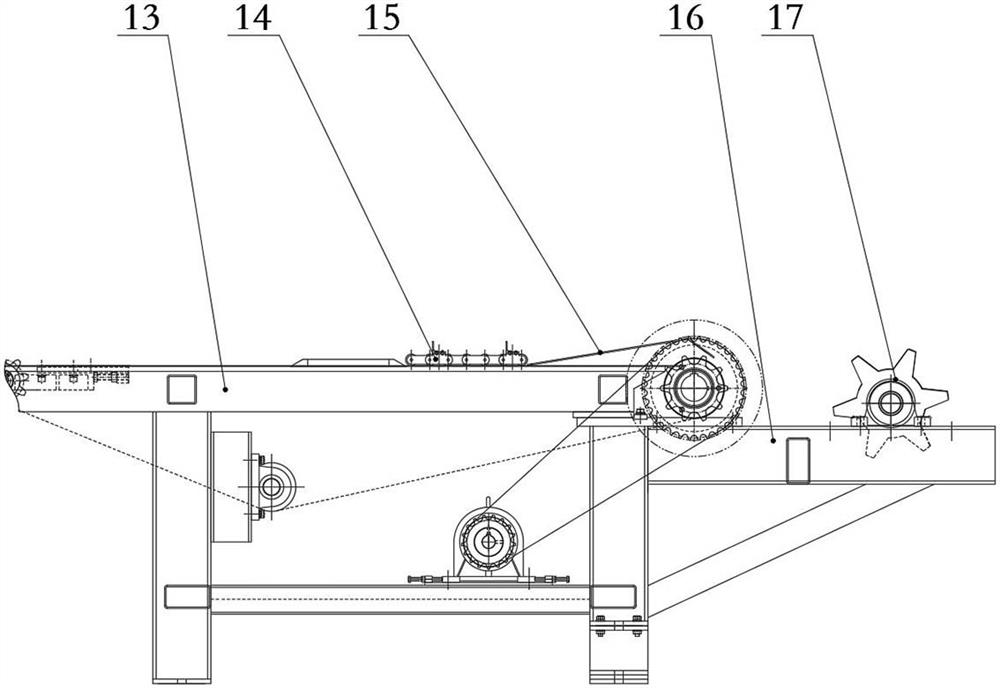

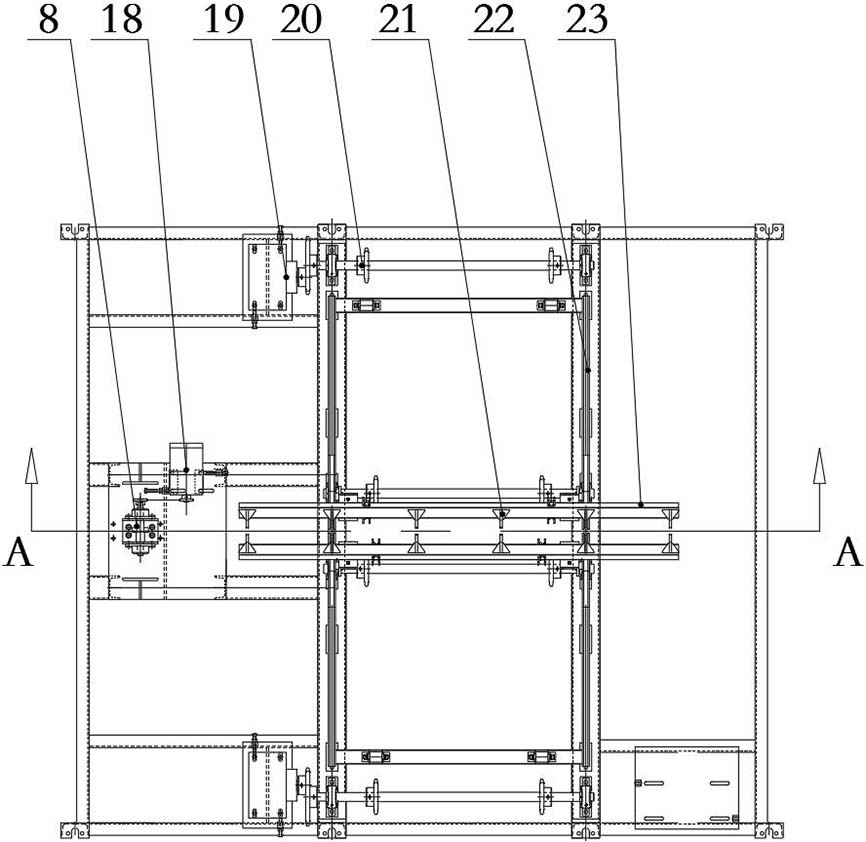

[0050] For pipeline operations, such as figure 1 The conveying direction of the material determined by the conveying platform 3 shown in is the basic direction, which is used to determine, for example, the front and rear directions of the assembly line. Specifically, the direction in which the material flows is the forward direction, and vice versa, the backward direction, and the front and rear correspond to the head tail. Correspondingly, in the plane defined by the conveying platform, the direction perpendicular to the front-to-back direction is the left-right direction, which can generally be expressed as the side direction, and the direction perpendicular to the conveying platform table is the up-down direction.

[0051] As mentioned in the Background Art section, the cotton mold body is relatively large. In addition, during packaging, it is necessary to use the packaging film 42 to bind the cotton tightly, and the cotton wrapped in the packaging film 42 is entangled wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com