Processing method of ready-to-stew cubilose

A processing method and bird's nest technology, applied in the field of food processing, can solve the problems of demanding physical fitness of processing personnel, inability to remove the fluff of swallow silk strips, and low cleaning effect, so as to achieve the preservation of the original ecological appearance, excellent cleaning effect and manpower saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

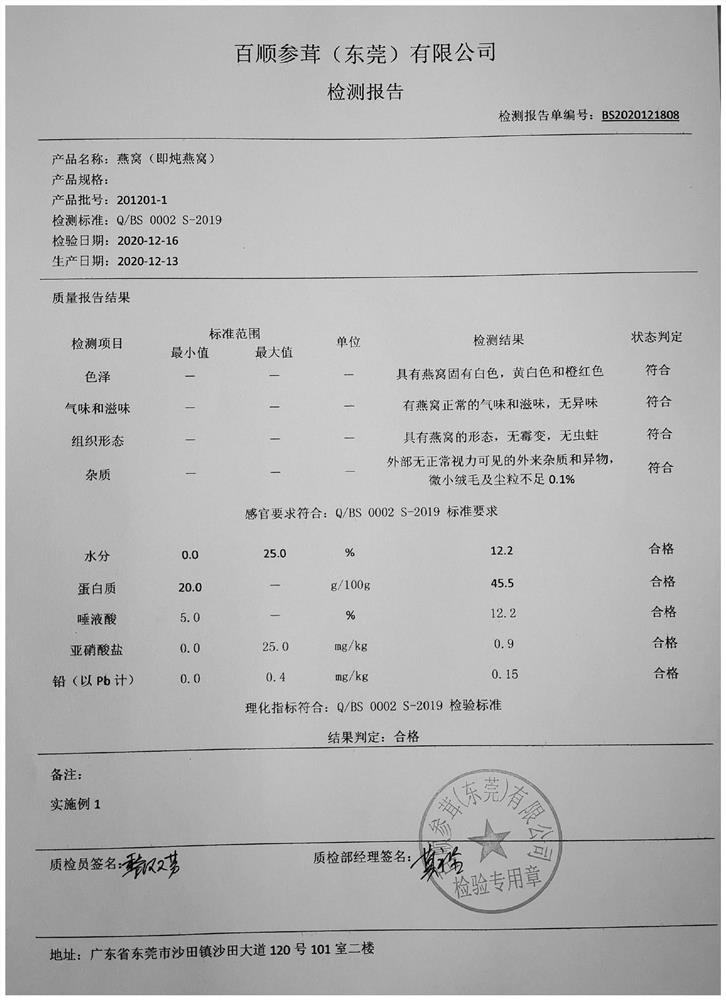

Embodiment 1

[0049] Embodiment 1 of the present invention discloses a kind of processing method of promptly stewing bird's nest, specifically comprises the following steps:

[0050](1) Take bird’s nest raw materials and sterilize them with ozone for 3 hours, then sort different specifications (bird’s nest, bird’s nest, bird’s cake and bird’s nest) according to the quality of the raw materials, and trim the bird’s horns of each bird’s nest; use 1.0Mpar high-pressure airflow to The dust particles and impurities on the surface of the bird’s nest are washed by air flow, and then pasteurized at 90°C for 15 seconds; add RO reverse osmosis pure water 3 times the weight of the raw material of the bird’s nest and soak for 45 minutes;

[0051] (2) Take the soaked bird’s nest and add a 0.5KW single-phase vibration machine to vibrate for 20 minutes, so that the bird’s nest is initially shaken; then use RO reverse osmosis pure water to rinse repeatedly for 2 to 4 times, and then put it in a dehydrator f...

Embodiment 2

[0056] Embodiment 2 of the present invention discloses a kind of processing method of promptly stewing bird's nest, specifically comprises the following steps:

[0057] (1) Take bird’s nest raw materials and use ozone to sterilize for 2 hours, then sort different specifications according to the quality of the raw materials, and trim the bird’s horns of each bird’s nest; use 0.8Mpar high-pressure airflow to wash the dust particles and impurities on the surface of the bird’s nest, and then clean it at 80 Insulate at ℃ for 15s for pasteurization; add RO reverse osmosis pure water 3 times the weight of bird's nest raw material to soak and wash for 35 minutes;

[0058] (2) Take the soaked bird’s nest and add it to a 0.5KW single-phase vibration machine to vibrate for 15 minutes, so that the bird’s nest is initially shaken; then use RO reverse osmosis pure water to rinse twice, and then run it in a dehydrator for 10 minutes for dehydration and separation. Obtain completely separated...

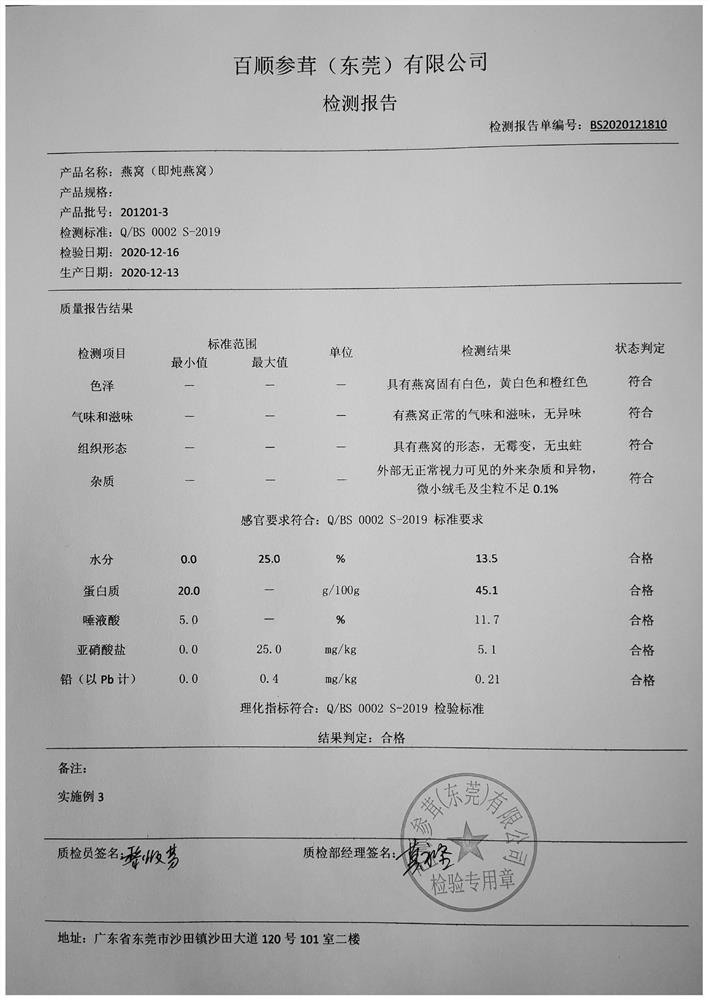

Embodiment 3

[0063] Embodiment 3 of the present invention discloses a kind of processing method of promptly stewed bird's nest, specifically comprises the following steps:

[0064] (1) Take bird’s nest raw materials and use ozone to sterilize for 3 hours, then sort different specifications according to the quality of the raw materials, and trim the bird’s horns of each bird’s nest; use 1.0Mpar high-pressure airflow to wash the dust particles and impurities on the surface of the bird’s nest, and then clean the bird’s nest at 75 Insulate at ℃ for 16s for pasteurization; add RO reverse osmosis pure water 3 times the weight of bird's nest raw material to soak and wash for 30 minutes;

[0065] (2) Take the soaked bird’s nest and add it to a 0.5KW single-phase vibration machine to vibrate for 10 minutes to make the bird’s nest preliminary shake; then use RO reverse osmosis pure water to rinse twice, and then put it in a dehydrator and run it for 15 minutes for dehydration and separation. Obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com