A kind of positive electrode lithium supplement material and preparation method and application thereof

A technology of lithium supplementation and positive electrode, which is applied in the field of positive electrode lithium supplementation materials and its preparation, can solve the problems of high equipment cost investment, residual non-lithium source components, and decreased discharge capacity, so as to improve processing and gas production performance, and reduce product residues. Lithium content, the effect of reducing the mixed discharge of lithium and nickel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

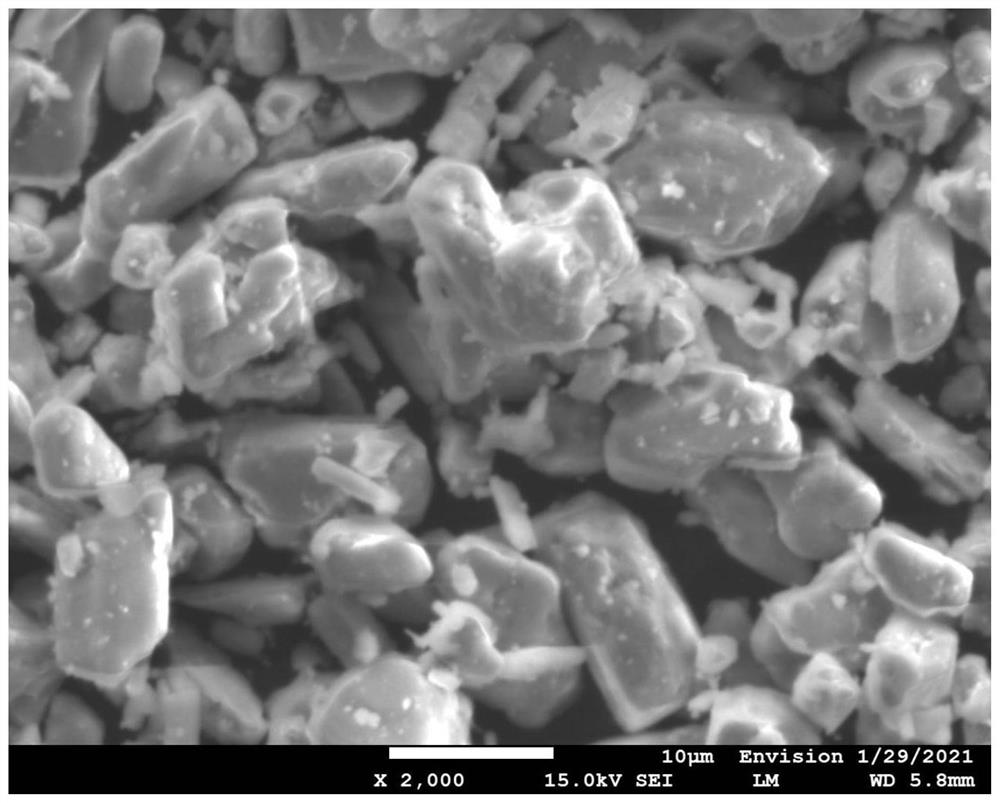

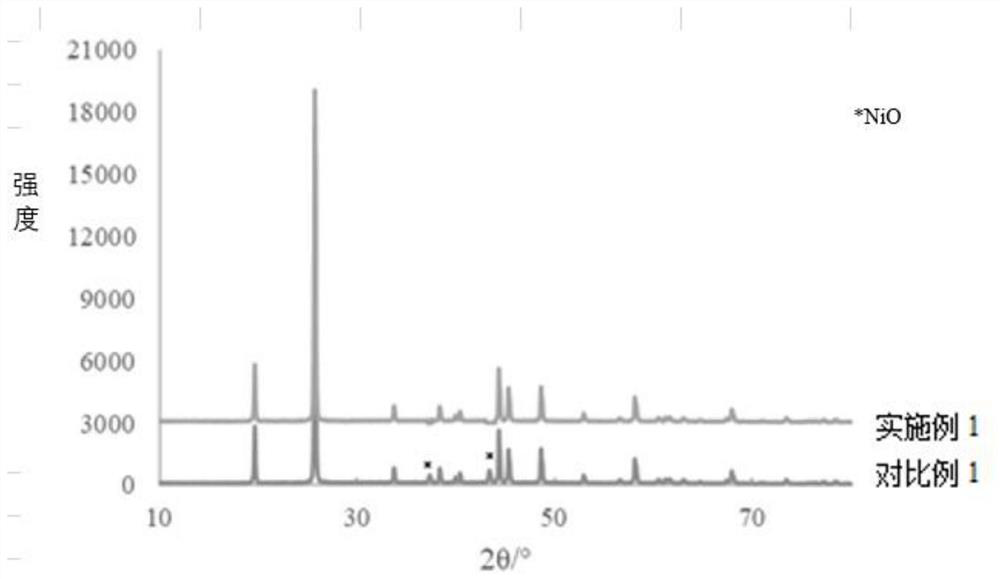

[0054] This embodiment provides a positive electrode lithium supplement material, and the positive electrode lithium supplement material is prepared by the following method:

[0055] (1) Dissolve 0.8mol / L nickel nitrate and 0.8mol / L copper nitrate in water to obtain a nickel and copper salt solution with a concentration of 0.8mol / L, add 1mol / L ammonia water while stirring, adjust pH to be 9.5 and let stand 8h, after filtration, washing and drying, a solid mixture is obtained, the solid mixture is raised to 300°C at a heating rate of 50°C / h, and the precursor is obtained by sintering for 6h;

[0056] (2) Mix the precursor obtained in step (1) with lithium carbonate in a molar ratio of 1.5:1, add 0.1% alumina at the same time, and mix under a vacuum of 78 kpa to obtain mixed powder, which is heated in nitrogen. In an inert atmosphere, at a heating rate of 6 °C / H, to 450 °C, one-step sintering for 2 h, and then heating to 800 °C at 10 °C / h, two-step sintering for 10 h. The furna...

Embodiment 2

[0059] This embodiment provides a positive electrode lithium supplement material, and the positive electrode lithium supplement material is prepared by the following method:

[0060] (1) Dissolve 0.8mol / L nickel sulfate and 0.8mol / L copper nitrate in water to obtain Ni and copper salt solution with a concentration of 1.0mol / L, add 1.2mol / L ammonia water while stirring, adjust the pH to be 10 and let stand 8h, after filtration, washing and drying, a solid mixture was obtained, the solid mixture was raised to 320°C at a heating rate of 55°C / h, and the precursor was obtained by sintering for 7h;

[0061] (2) Mixing the precursor obtained in step (1) with lithium hydroxide in a molar ratio of 1.5:1, adding 0.15% titanium oxide by mass at the same time, and mixing under a vacuum of 76 kpa to obtain a mixed powder, which is then heated under nitrogen. In an inert atmosphere, at a heating rate of 8°C / H, to 480°C, one-step sintering for 2h, and then heating to 900°C at 15°C / h, two-ste...

Embodiment 3

[0063] The only difference between this embodiment and embodiment 1 is that the temperature of the one-step sintering in step (2) is 400° C., and other conditions and parameters are exactly the same as those of embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com