Turnover mechanism for packaging plastic package diode and implementation method of turnover mechanism

A technology of flipping mechanism and diode, applied in conveyor objects, transportation and packaging, electrical components, etc., can solve problems such as large torque, motor wear, difficult operation, etc., and achieve the effect of prolonging service life, ensuring continuity and flexible use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

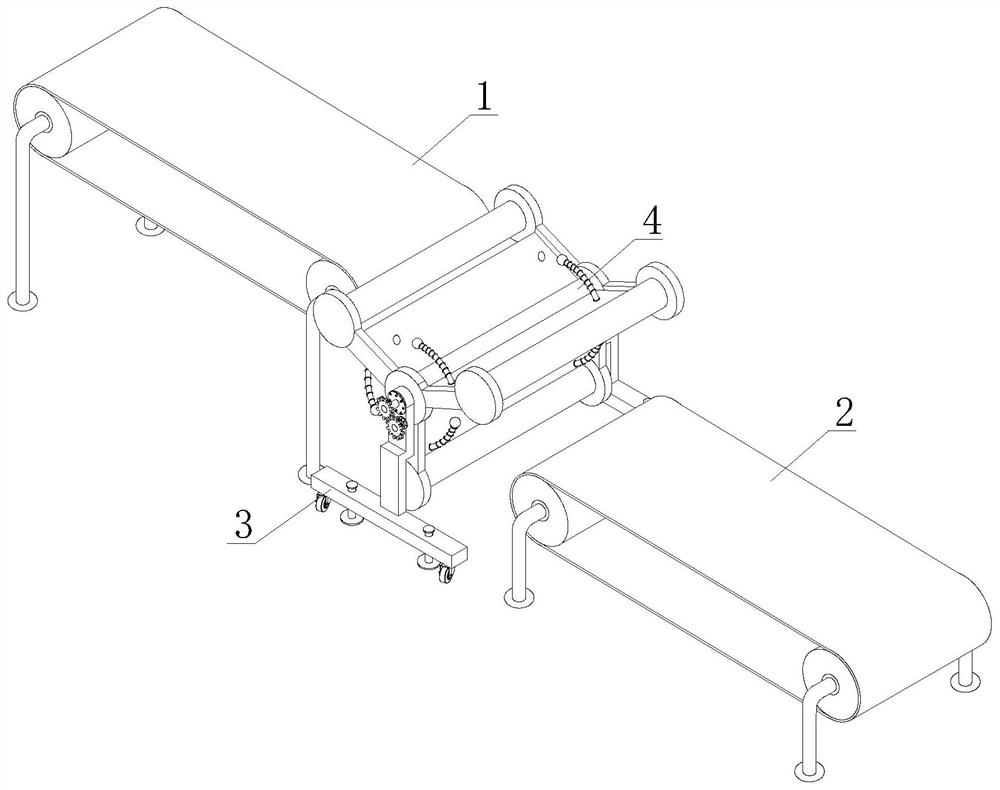

[0040] In order to better demonstrate the implementation process of the flipping mechanism for plastic-encapsulated diode packaging, this embodiment now proposes an implementation method for the flipping mechanism for plastic-encapsulated diode packaging, including the following steps:

[0041] Step 1: Install the flip bracket 3 between the first conveyor belt 1 and the second conveyor belt 2, and drive the fixed chassis 33 and the ground support by rotating the threaded column 331, and fix the position of the flip bracket 3;

[0042] Step 2: the lower sheet of the first conveyor belt 1 is transported by the first conveyor belt 1, and moves to the end of the first conveyor belt 1 close to the flip bracket 3, and the driving motor 35 drives the first gear 351 to rotate, and is driven by the second gear 441, Turning device 4 rotates;

[0043] Step 3: When the lower material piece moves to one end suspended in the air, the end of the flipping device 4 with the movable roller 42 r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com