Preparation method of lignocellulose three-component bi-crosslinking gel, the gel and application

A lignocellulose, three-component technology, applied in the field of preparation of lignocellulose three-component double cross-linked gel, can solve the problem of difficult preparation of high-solid gel with high-strength gel, difficulty in increasing gel solid content, chemical cross-linking problems such as difficulty in preparation, to achieve the effect of solving the difficulty of efficient utilization, improving the effective utilization rate, and reducing the cost of preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

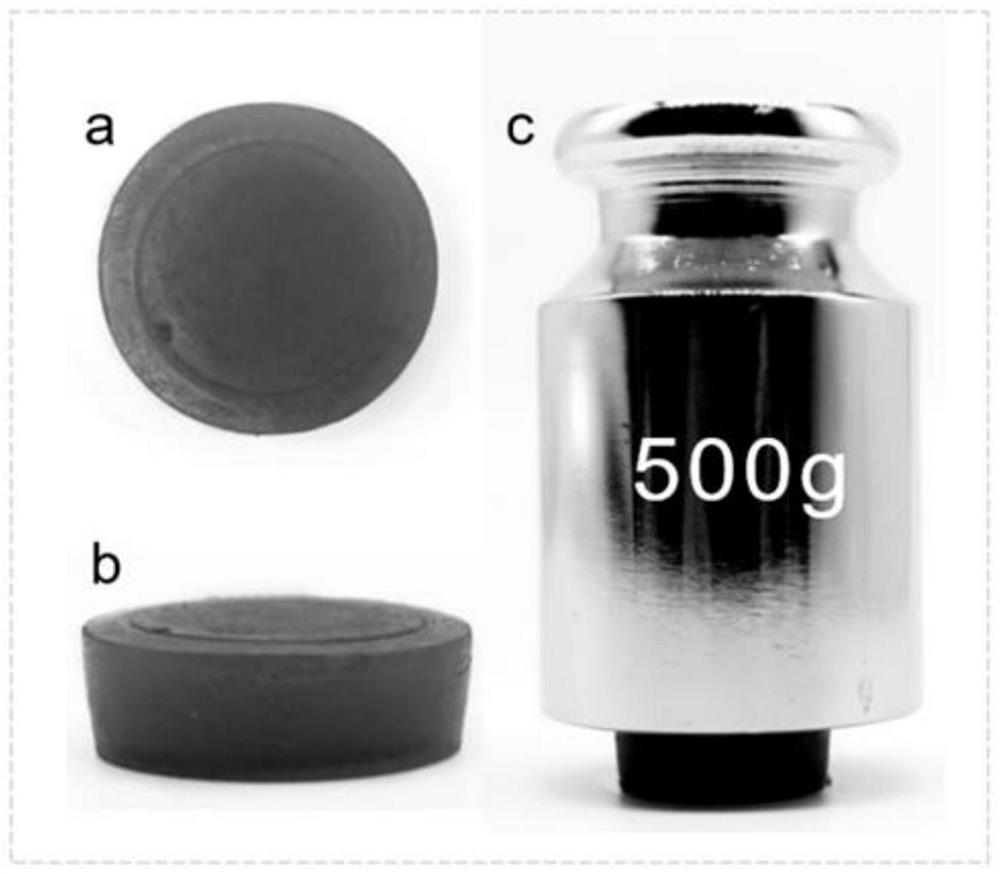

[0040] According to one aspect of the present invention, as figure 1 Shown, the preparation method of lignocellulose three-component double-crosslinked gel is provided, and this preparation method comprises the following steps:

[0041] S1. Using cellulose raw materials to prepare a nanocellulose dispersion, and dissolving hemicellulose and lignin in corresponding solvents to obtain a hemicellulose solution and a lignin solution, respectively;

[0042] S2, uniformly mixing the nanocellulose dispersion, hemicellulose solution and lignin solution to obtain a lignocellulose dispersion containing nanocellulose, hemicellulose and lignin;

[0043] S3. Put the three-component lignocellulose dispersion in a double-steam bath closed environment with dual functions of physical crosslinking and chemical crosslinking to prepare lignocellulose three-component double-crosslinked gel.

Embodiment 1

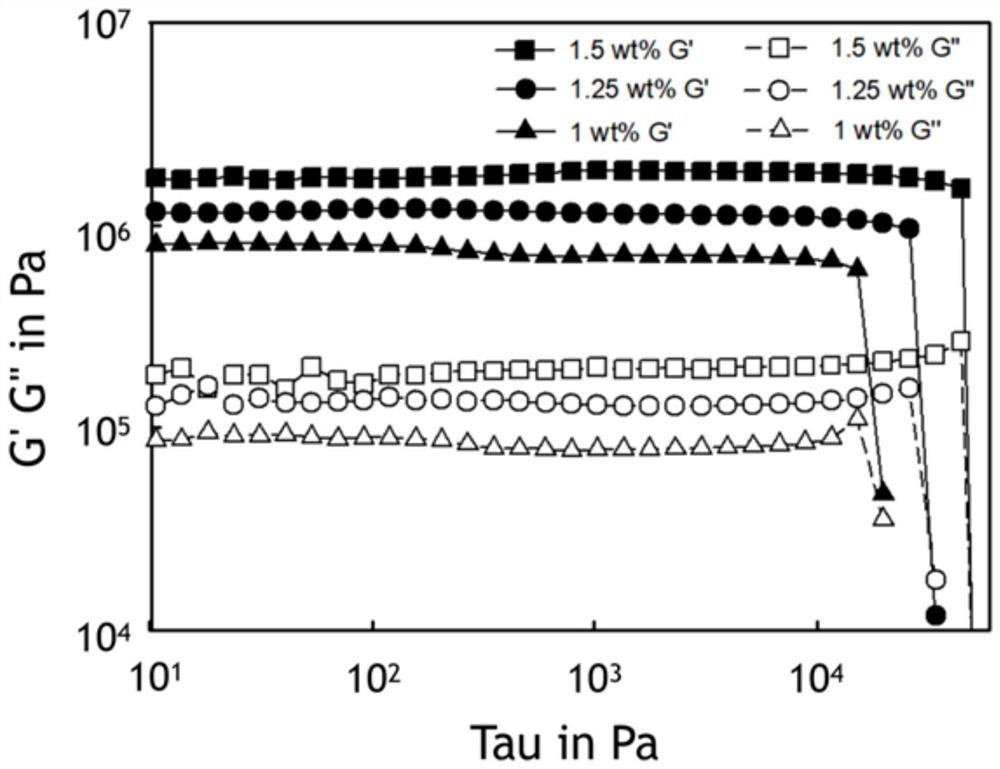

[0047] Take a nanocellulose dispersion equivalent to 0.0750 g of absolute dry mass and add a certain amount of distilled water to fully mix to obtain a uniform and transparent dispersion of 5 g. Centrifuge to remove air bubbles and put it into a mold. Put a certain amount of ammonia water and ring Oxychloropropane provides a gas environment where physical and chemical cross-linking can occur, and the dispersion is placed in a double-steam bath environment, and reacted at 65° C. for 3 hours to obtain a cellulose double-cross-linked gel. The solid content in the obtained cellulose double-crosslinked gel was 1.5 wt%.

[0048] Transfer the reacted cellulose double-crosslinked gel to a clean beaker filled with ethanol to terminate the chemical reaction and perform solvent replacement, and replace the ethanol every few hours to ensure complete solvent replacement. Viscoelasticity measurements were performed on cellulose double-crosslinked gels to characterize their strength.

Embodiment 2

[0050] Take the nanocellulose dispersion equivalent to 0.0675g dry mass, dissolve 0.0075g glucomannan in distilled water, fully mix the above two raw materials and add a certain amount of distilled water to obtain 5g uniform and transparent dispersion, and remove it by centrifugation. Bubble and put into the mold, put a certain amount of ammonia water and epichlorohydrin into the airtight container to provide a gas environment where physical and chemical crosslinking can occur, place the dispersion in a double steam bath environment, and react at 65 °C After 3 hours, a lignocellulose two-component double-crosslinked gel was obtained. The obtained lignocellulose two-component double-crosslinked gel has a solid content of 1.5 wt%, and a cellulose:hemicellulose ratio of 9:1 (mass ratio).

[0051] The reacted lignocellulose two-component double-crosslinked gel was transferred to a clean beaker filled with ethanol to terminate the chemical reaction and perform solvent replacement, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com