System and method for producing crystallized xylose by using xylose mother liquor

A technology of xylose mother liquor and xylose, which is applied in the direction of sugar derivatives, sugar derivatives, sugar derivatives preparation, etc., can solve the problems of underutilized added value, affecting centrifuge yield and efficiency, and increasing processing costs, etc. Achieve the effects of improving production efficiency and equipment utilization, centrifugation yield and centrifugation efficiency, and increasing added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

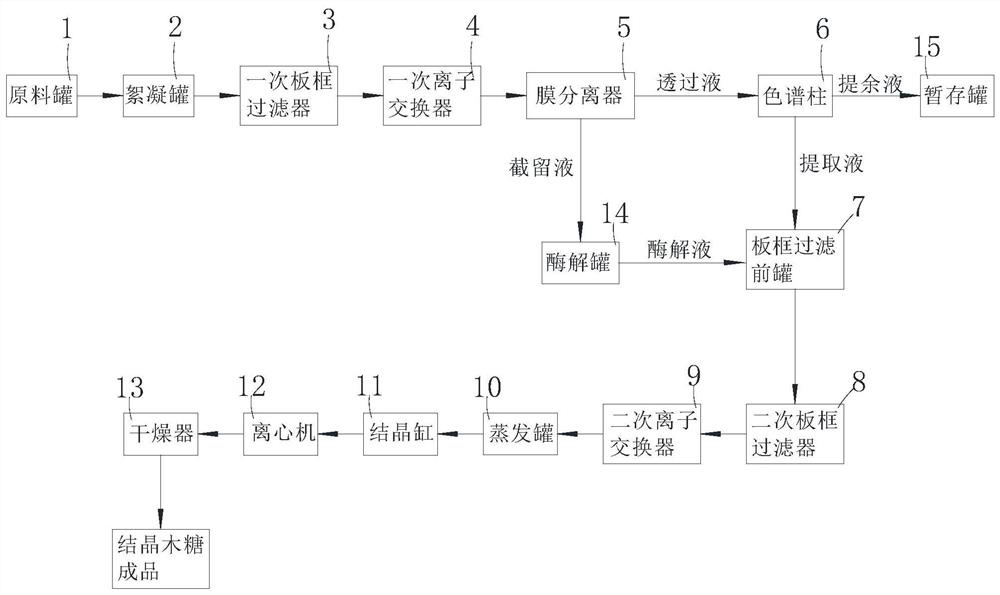

Image

Examples

Embodiment 1

[0033] In the first embodiment of the method for producing crystallized xylose utilizing xylose mother liquor of the present invention, the xylose mother liquor whose xylose purity is 45% is an example with a solids concentration of 50%, and xylose in the total sugar of the xylose mother liquor The content of sugar is 45%, the content of arabinose is 15%, the content of glucose is 16%, the content of mannose is 10%, the proportion of galactose is 7%, and the proportion of xylan is 7%.

[0034] The method comprises the steps of:

[0035] Step 11, adding a flocculant to the xylose mother liquor with a solid concentration of 50% for flocculation treatment, controlling the flocculation temperature to 50°C to 60°C, and the flocculation time to 30min to 60min.

[0036] Step 12. The material after flocculation is put into the tank before primary plate and frame filtration, and activated carbon with a mass ratio of 1% is added, mixed at 65°C for 30 minutes, and then filtered through p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| translucency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com