Automobile brake-by-wire system

A technology of automotive wires and controllers, applied in the direction of brakes, brake transmissions, vehicle components, etc., can solve the problems of reducing motor speed and power requirements, insufficient carrying capacity, motor stalling, etc., to improve carrying capacity and use Longevity, reduction of potential safety hazards, effects of size reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

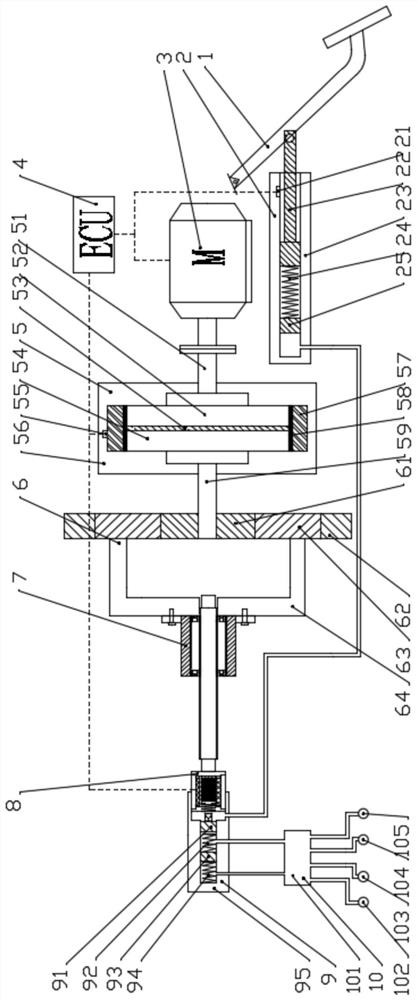

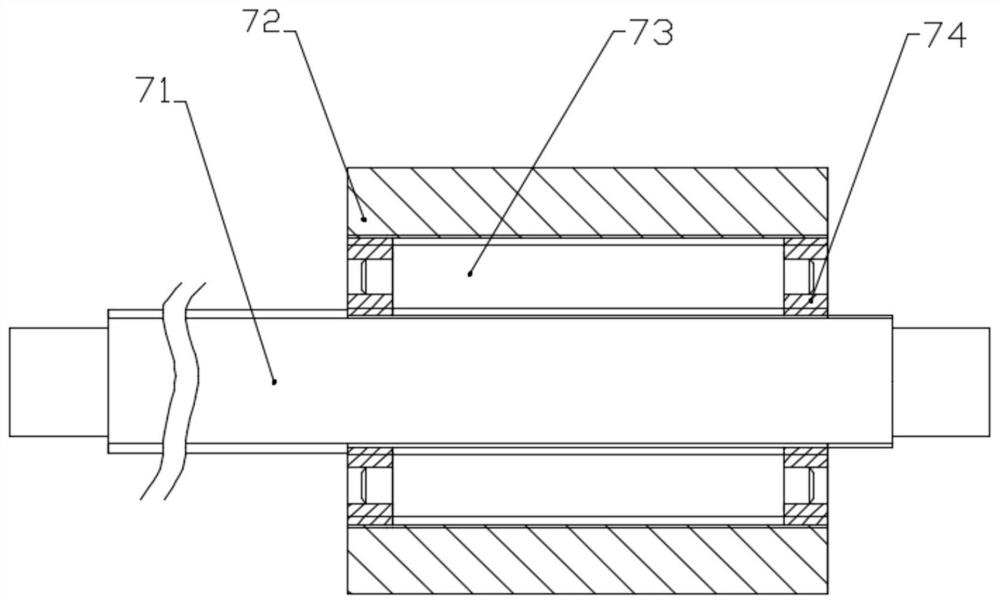

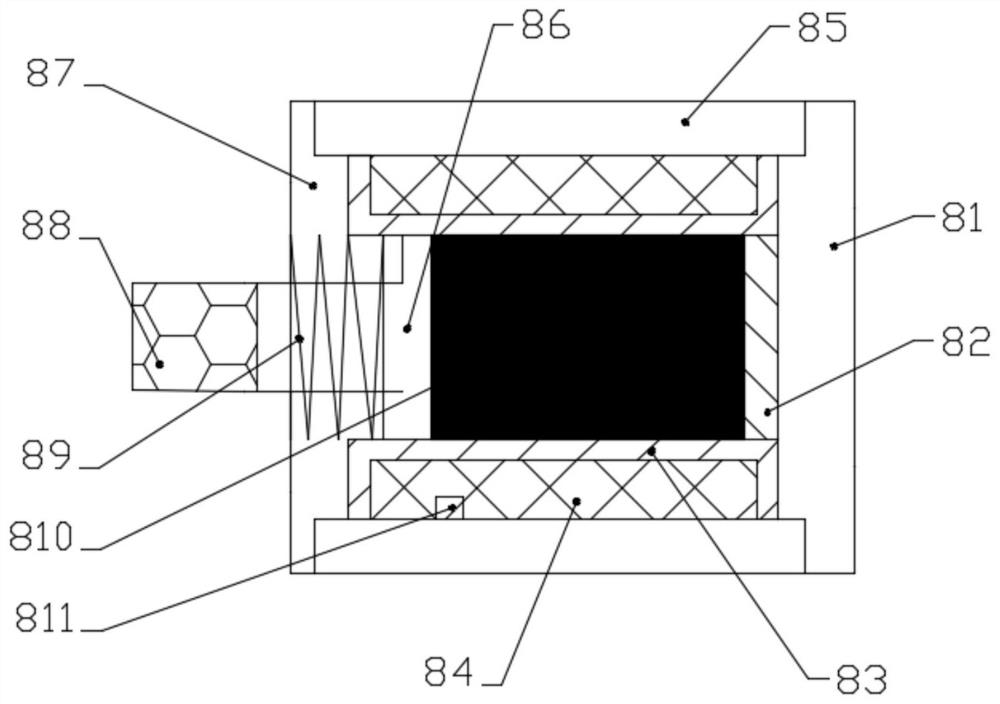

[0043] The automobile brake-by-wire system proposed by the present invention has a structure such as Figure 1-3 As shown, it includes brake pedal 1, pedal simulator 2, motor 3, controller 4, magneto-rheological clutch 5, planetary gear train 6, planetary roller screw mechanism 7, giant magnetostrictive drive mechanism 8, master cylinder 9. Brake actuator 10.

[0044] The magneto-rheological clutch 5 includes a clutch housing 56, an input shaft 51, a coil 57, a driving disc 52, a magneto-rheological fluid 53, a driven disc 54, an output shaft 59, and a first signal sensor 55; the clutch housing 56 and The motor housing (not shown in the figure) is fixedly connected, the input shaft 51 is connected with the transmission shaft of the motor 3 through a coupling, the driving disc 52 is connected with the input shaft 51 through a key, and the driving disc 52 and the driven disc 54 There is a certain amount of magnetorheological fluid 53 sealed between them. The output shaft 59 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com