A plasma cutting auxiliary platform

An auxiliary platform and plasma technology, applied in welding/cutting auxiliary equipment, plasma welding equipment, auxiliary devices, etc., can solve problems such as prolonged working time, uneven cutting surface, and affecting the use of thin plates, so as to ensure work quality and simple operation , The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

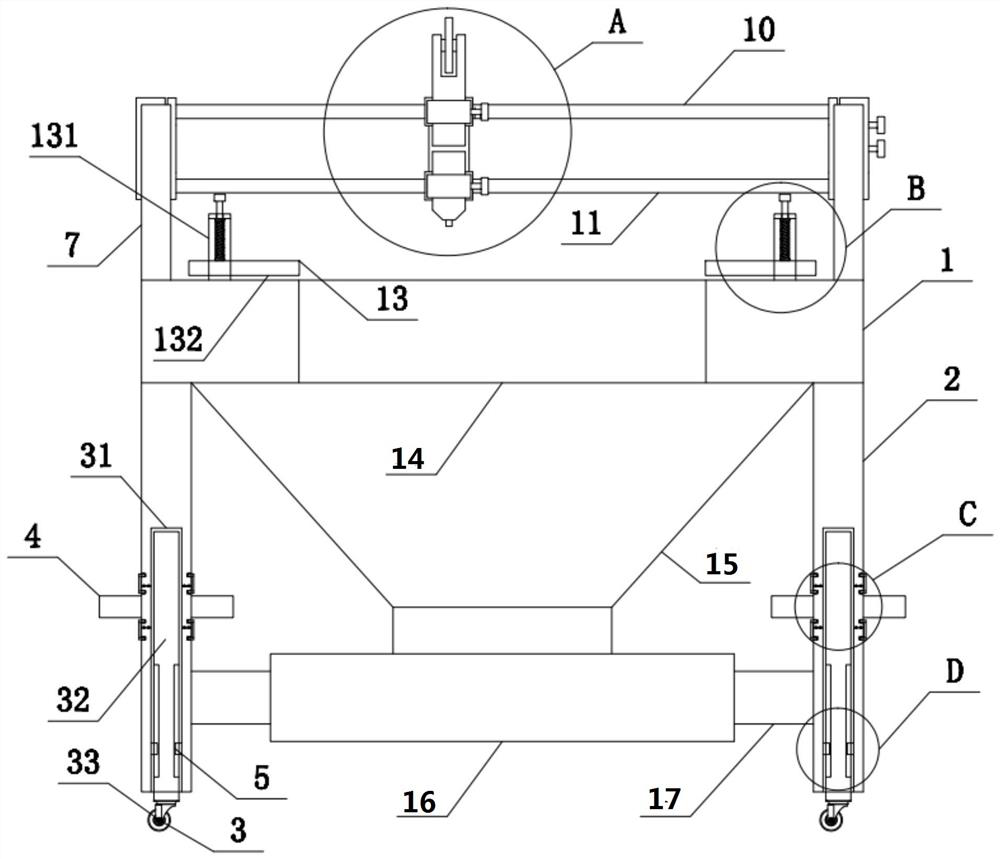

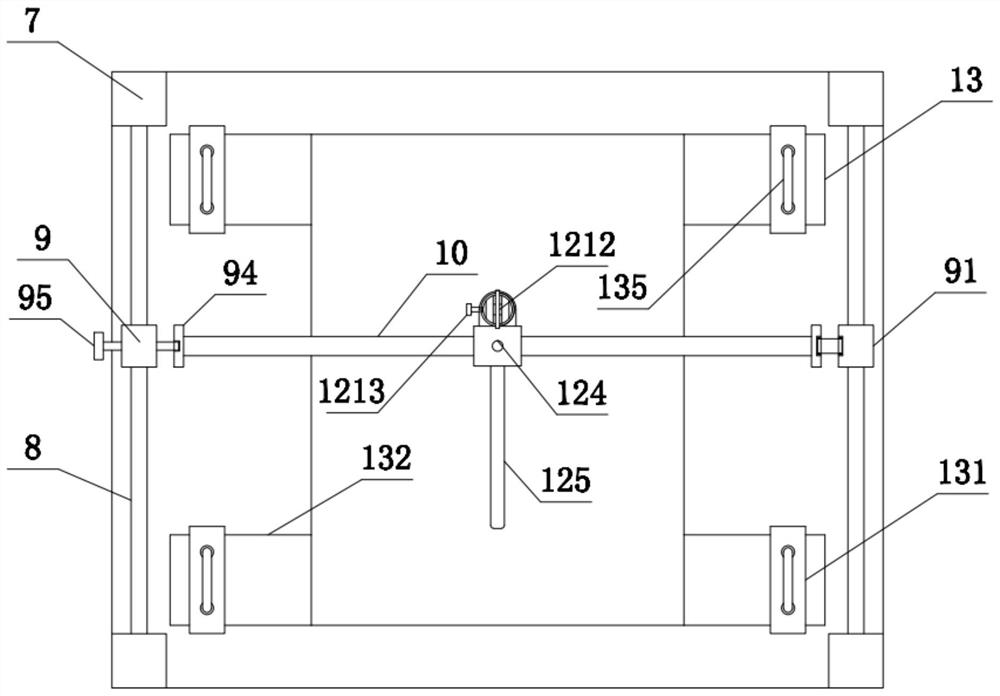

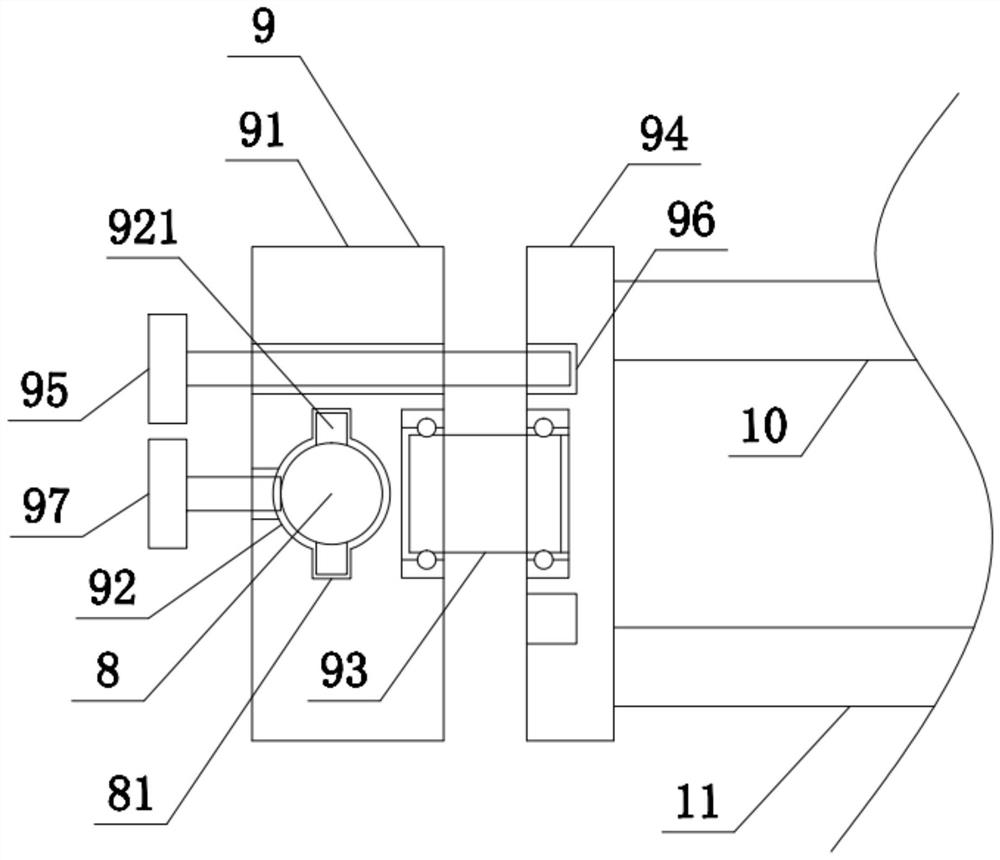

[0035] see Figure 1-7 , a plasma cutting auxiliary platform, comprising a table 1, the lower end of the table 1 is fixedly connected with a leg 2, the lower end of the leg 2 is fixedly installed with a moving mechanism 3, and the upper end of the table 1 is chamfered Both are fixedly installed with a column 7, the side wall of the column 7 is fixedly connected with a first sliding rod 8, the outer wall of the first sliding rod 8 is slidably connected with a positioning mechanism 9, and the upper surface of the table 1 is fixedly installed with a fixing mechanism 13. There is a through groove 14 inside the platform 1, and the lower end of the platform 1 is fixedly connected with an inclined bucket 15, and the inclined bucket 15 communicates with the through groove 14, and the lower end of the inclined bucket 15 is fixedly connected to There is a collection box 16, the side wall of the collection box 16 is fixedly connected with a third connecting rod 17, and one end of the thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com