Method for producing yoghurt by Ohm sterilization process

A technology of ohmic sterilization and yogurt, which is applied in the direction of milk preservation, milk preparations, dairy products, etc., and can solve the problems of long heating time, poor stability, and high amount of stabilizer added

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

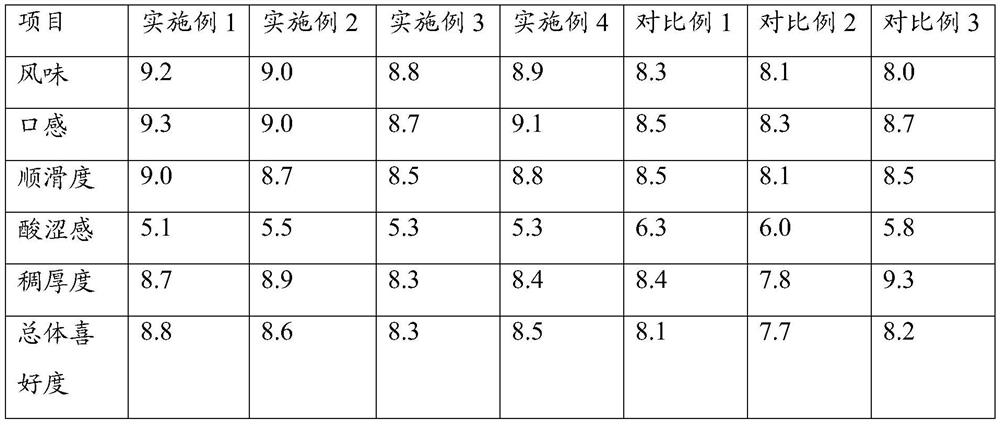

Examples

Embodiment 1

[0057] 1. Yogurt recipe

[0058] Raw milk: 900 parts by weight

[0059] White sugar: 90 parts by weight

[0060] Stabilizer: 10 parts by weight (wherein the stabilizer consists of pectin and gelatin, and pectin:gelatin=2:7)

[0061] Appropriate amount of fermentation bacteria

[0062] 2. Preparation method

[0063] a. Ingredients: heat up the milk to 70°C, add white sugar and stabilizer, shear and mix for 15 minutes, and cool;

[0064] b. Sterilization: Sterilize at 135°C for 4s, then cool to 42°C;

[0065] c. Fermentation: inoculate at 42°C, ferment for 6 hours, demulsify, and cool;

[0066] d. Preheating: preheating to 35°C;

[0067] e. Ohmic sterilization: sterilization at 75°C for 30s, heating rate of 2.9°C / s, time to reach the sterilization temperature of 13.8s; cooling to 20°C;

[0068] f. Aseptic filling.

[0069] The protein content of the yogurt in this embodiment is 2.7%, the texture of the product is uniform and delicate, the taste is smooth and full, and th...

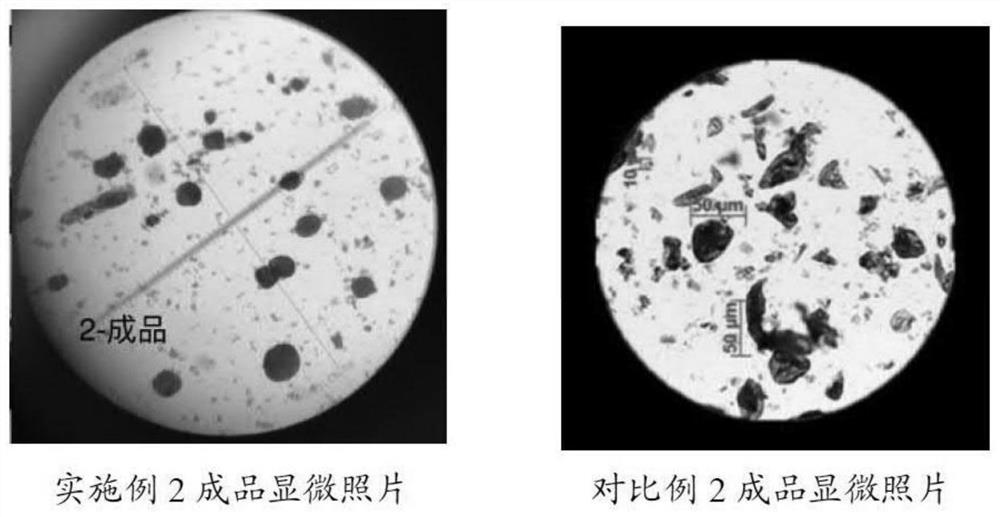

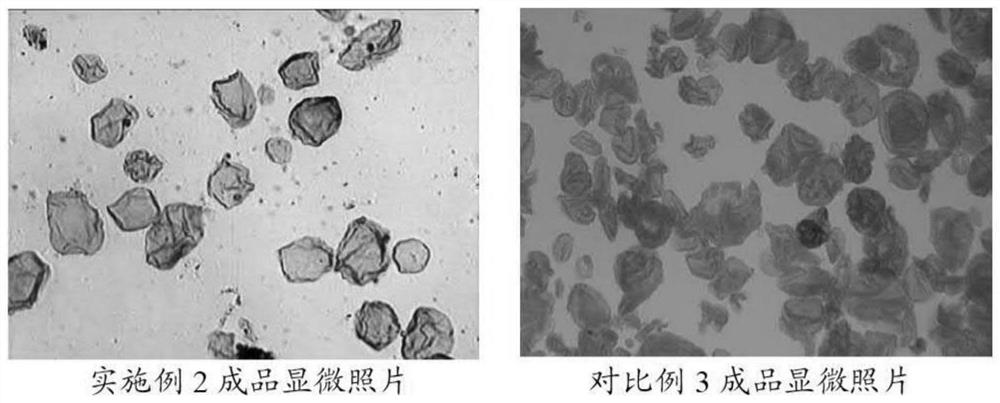

Embodiment 2

[0071] 1. Yogurt recipe

[0072] Raw milk: 900 parts by weight

[0073] White sugar: 90 parts by weight

[0074] Stabilizer: 13 parts by weight (wherein the stabilizer consists of pectin and modified starch, and pectin:modified starch=1:9)

[0075] Appropriate amount of fermentation bacteria

[0076] 2. Preparation method

[0077] a. Ingredients: heat up the milk to 45°C, add white sugar and stabilizer, shear and mix for 20 minutes, and cool;

[0078] b. Sterilization: Sterilize at 95°C for 300s, then cool to 45°C;

[0079] c. Fermentation: Inoculation at 45°C, fermentation for 5.5 hours, demulsification, cooling;

[0080] d. Preheating: preheating to 33°C;

[0081] e. Ohmic sterilization: Sterilize at 80°C for 25s, heat up at 4.2°C / s, and take 11.2s to reach the sterilization temperature; cool to 26°C;

[0082] f. Aseptic filling.

[0083] The protein content of the yogurt in this embodiment is 2.7%, the texture of the product is uniform and delicate, the taste is smo...

Embodiment 3

[0085] 1. Yogurt recipe

[0086] Raw milk: 900 parts by weight

[0087] White sugar: 95 parts by weight

[0088] Stabilizer: 9 parts by weight (wherein the stabilizer consists of gellan gum and modified starch, and gellan gum:modified starch=1:30)

[0089] Appropriate amount of fermentation bacteria

[0090] 2. Preparation method

[0091] a. Ingredients: heat up the milk to 30°C, add white sugar and stabilizer, shear and mix for 30 minutes, and cool;

[0092] b. Sterilization: Sterilize at 90°C for 240s, then cool to 37°C;

[0093] c. Fermentation: Inoculation at 37°C, fermentation for 10 hours, demulsification, cooling;

[0094] d. Preheating: preheating to 36°C;

[0095] e. Ohmic sterilization: Sterilize at 65°C for 60s, heating rate is 2.5°C / s, and the time required to reach the sterilization temperature is 11.6s; cool to 25°C;

[0096] f. Aseptic filling.

[0097] The protein content of the yogurt in this embodiment is 2.7%, the texture of the product is uniform an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com