Pressing device on aluminum substrate production line

A technology of pressing device and aluminum substrate, applied in the field of pressing device, can solve the problems of not meeting actual production requirements, slippery board degumming, etc., so as to shorten the cold pressing feeding and discharging time, improve the pressing efficiency, and improve the pressing The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

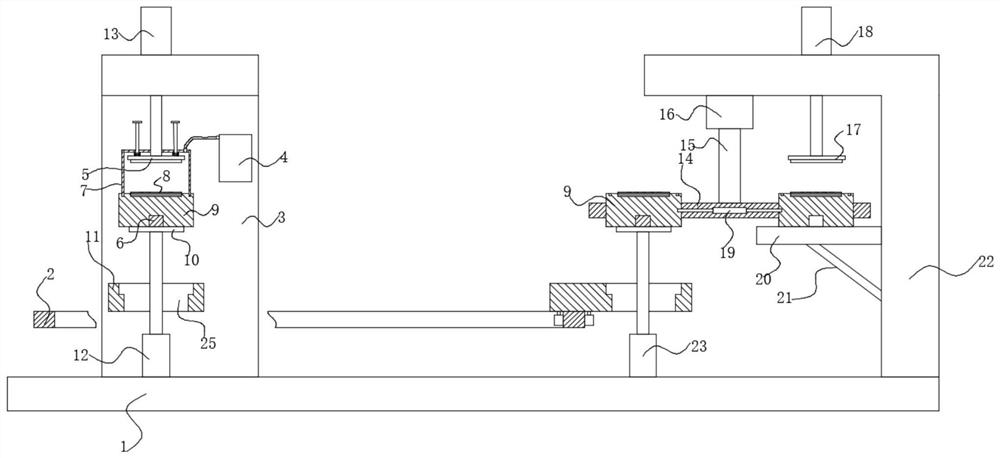

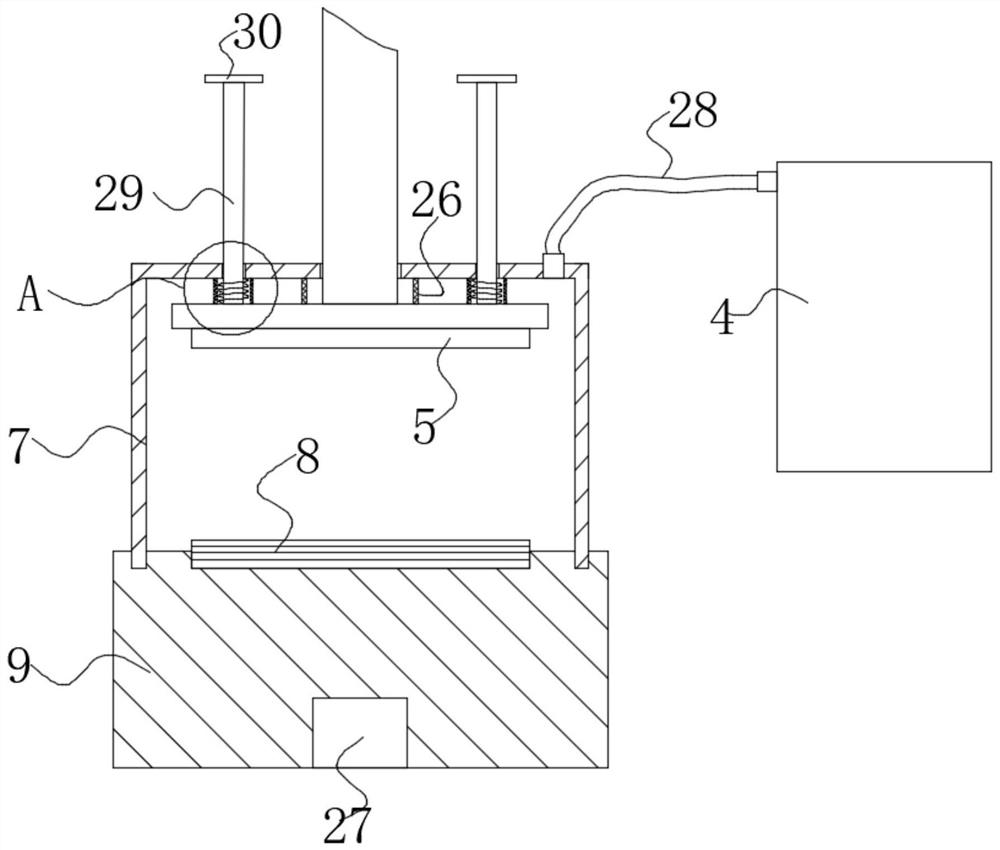

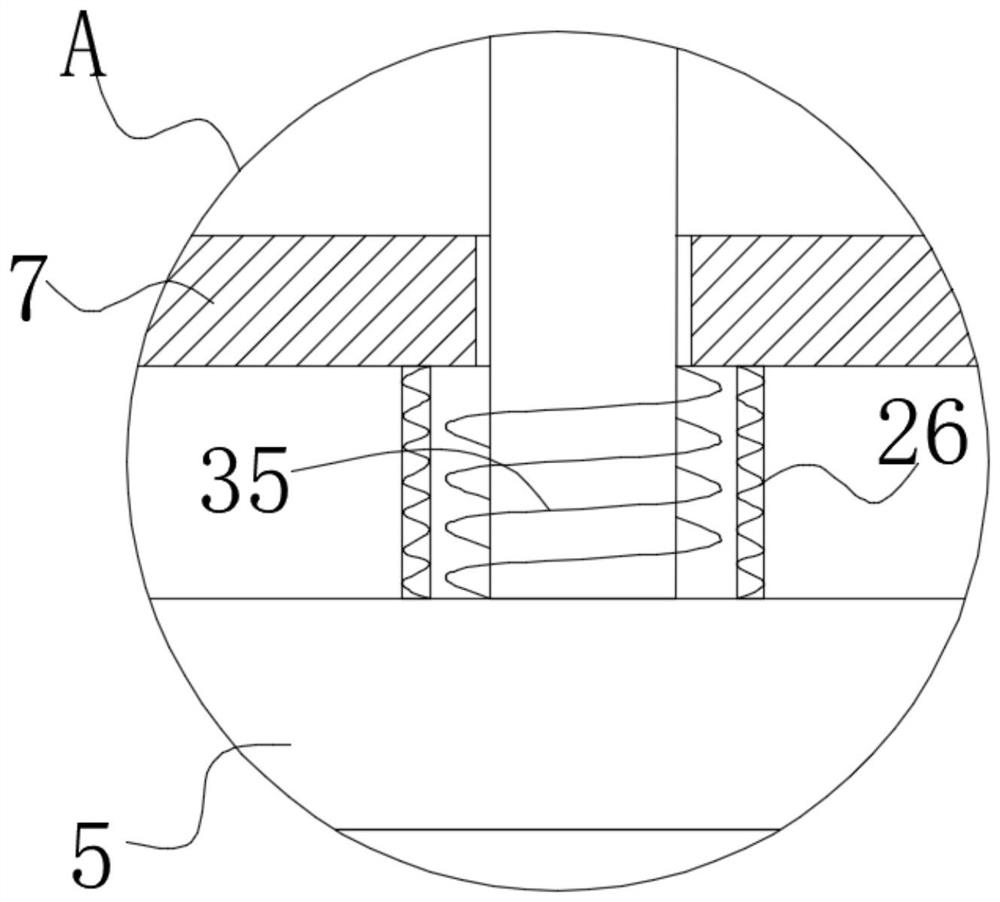

[0028] see figure 1 , in this embodiment, a pressing device on an aluminum substrate production line includes a machine base 1, a ring rail 2 assembled on the machine base 1 and used for surrounding transportation of the aluminum substrate 8, arranged on the outside of the ring rail 2 and respectively A hot pressing assembly and a cold pressing assembly for hot pressing and cold pressing the aluminum substrate 8, at least two sliding seats 11 are slidably installed on the ring rail 2, and the frame also includes a The drive mechanism for the seat 11 to slide on the ring rail 2. The outer part of the slide seat 11 away from the ring rail 2 is provided with a stepped groove 25. The stepped groove 25 runs through up and down. The separa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com