Box-type switching station

A switch station and box-type technology, applied in substation/switch layout details, substation/switchgear cooling/ventilation, electrical components, etc., can solve the problems of limited operating space for staff, difficult deployment, and reduced service life of components. , to achieve the effect of increasing display space, increasing heat dissipation efficiency, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

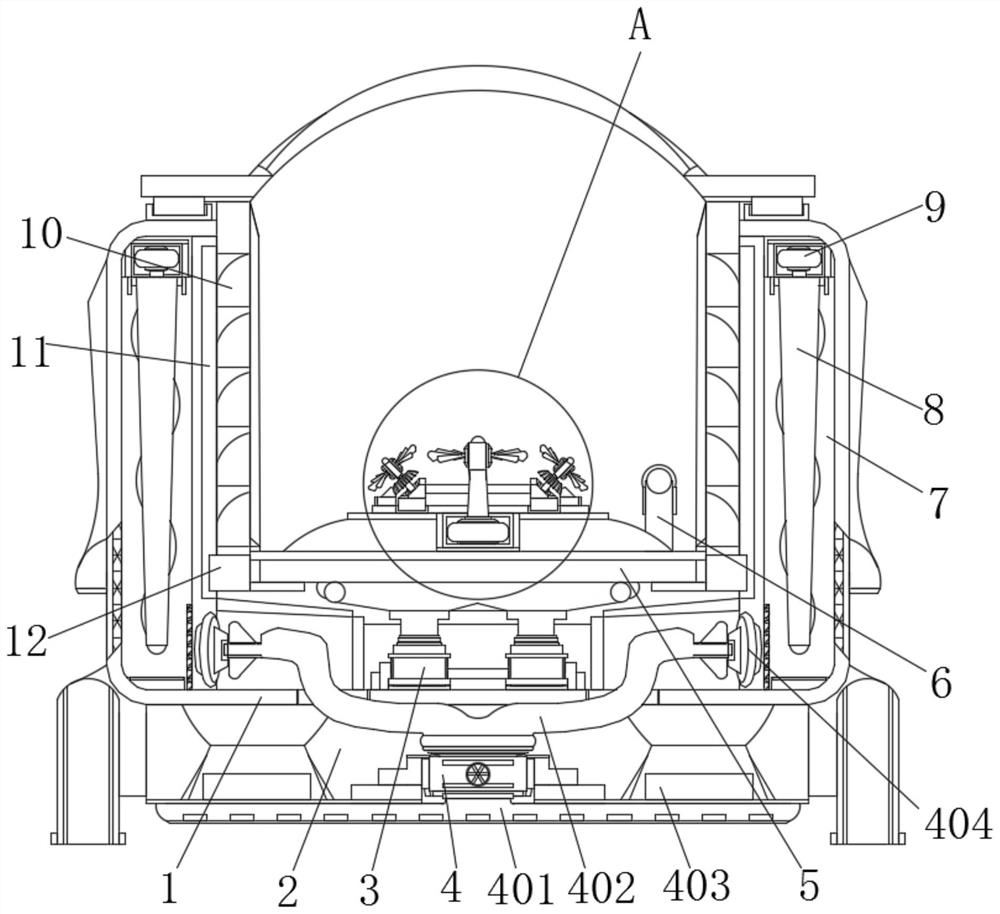

[0038] Example 1, such as figure 1 As shown, the humidity under the equipment is detected by the humidity sensor 403. When the humidity reaches a certain index, the suction fan 4 and the servo motor 9 can be started through the control box 13, and the cooling gas inside the inner box 5 is released from the exhaust port 10. After the outflow, the start of the servo motor 9 can drive the spiral guide rod 8 to guide the gas downward, and after the gas is introduced into the lower part, the start of the suction fan 4 and the communication and cooperation of the shunt pipe 402 and the suction port 404 will guide the flow. The gas under the wind chamber 7 is absorbed, and the absorbed gas flows into the permeable plate 401 under negative pressure, and through the evenly distributed through holes of the permeable plate 401, the absorbed heat dissipation gas evenly covers the bottom groove 2 and the bottom of the permeable plate 401, Furthermore, the moisture sensed by the humidity se...

Embodiment 2

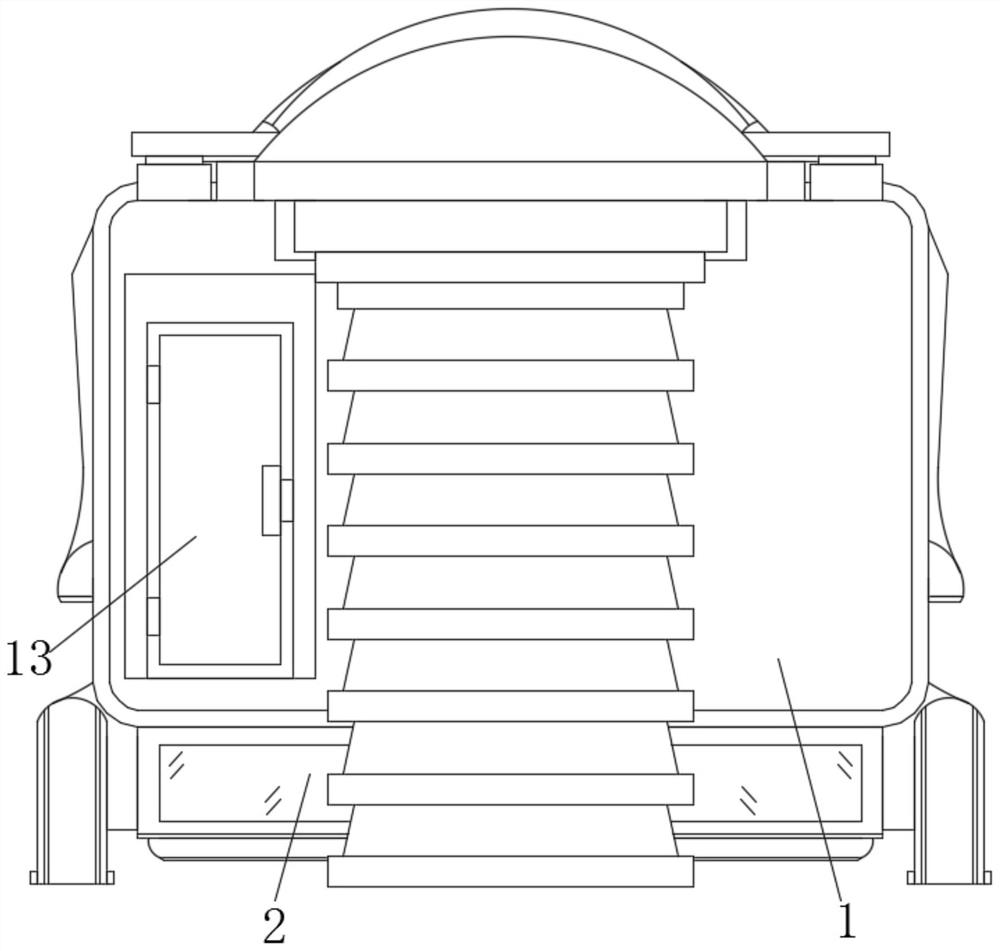

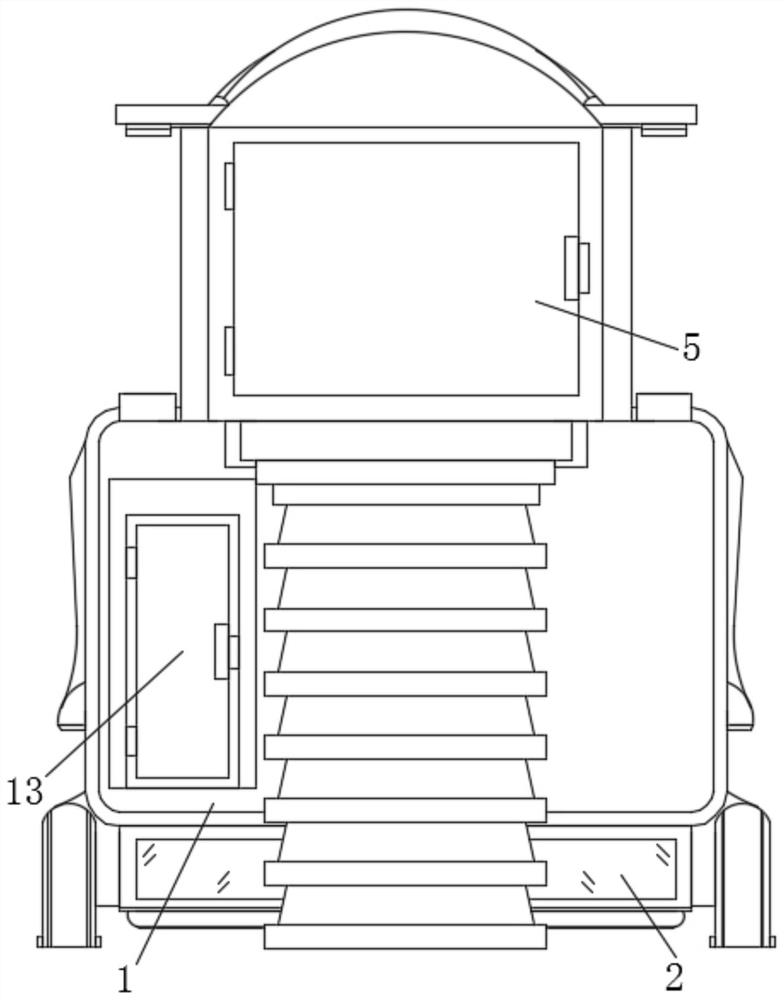

[0039] Example 2, such as Figure 1-3 As shown, the temperature in the inner box 5 is detected by the temperature sensor 6. When the temperature in the inner box 5 is high, the electric push rod 3 can be started through the control box 13, and the start of the electric push rod 3 is used to drive the inner box. The box body 5 is lifted as a whole, and during the rising of the inner box body 5, four groups of guide blocks 12 are driven to slide and rise under the cooperation of the guide rail columns 11, so that the inner box body 5 can be fully expanded out of the outer box body 1. At this time, the first The fan blades 145 and two sets of second fan blades 146 perform heat dissipation, and the radiated gas can be directly discharged from the exhaust port 10 to speed up the circulation of the gas, prevent the heat source from being concentrated in the equipment and affect the components, and use steps and platforms to After the inner box body 5 is unfolded, the structural comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com