High-brightness multi-channel optical machine structure

A high-brightness, multi-channel technology, applied in optics, instruments, projection devices, etc., can solve the problems of VOC carbonization and blackening, reducing brightness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

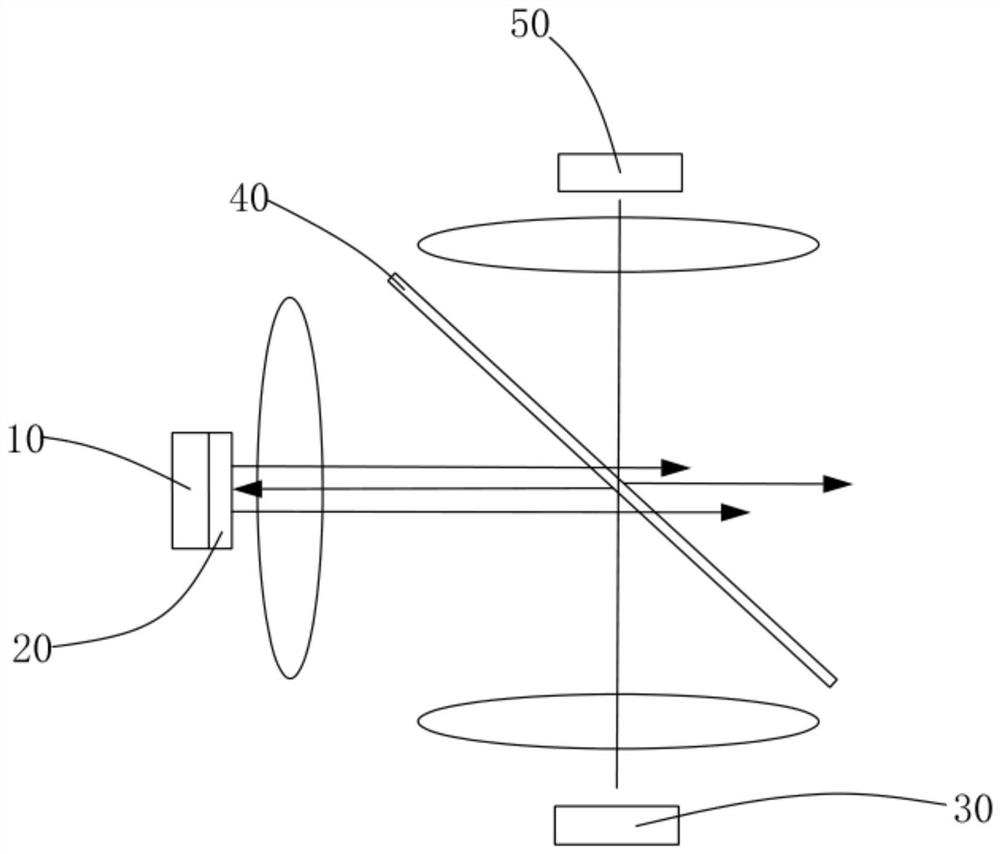

[0054] See figure 1 , A multi-channel optical machine architecture provided by the first embodiment of the present invention, including:

[0055] The first solid state light-emitting chip 10, the first solid state light-emitting chip 10 is used to emit light of the first spectrum, wherein the light of the first spectrum can be green or red.

[0056] The first fluorescent sheet 20 is provided at the light emitting end of the first solid state light emitting chip 10, wherein the first fluorescent sheet 20 is close to the first solid light emitting chip 10 through a high thermal conductive interface material. ;

[0057] The first excitation optical chip 30 is used to emit first excitation light, wherein the first excitation light is excited blue.

[0058] The first combined light filter 40 is used to guide the first excitation light incident the first fluorescent sheet from the top side of the first fluorescent sheet 20, and generates An excited light, in particular, the first-fittin...

Embodiment 2

[0065] In one embodiment of the invention, please refer to figure 1 Most of the first spectrum of the first spectrum is transmitted through the first fluorescent sheet 20 without excitation, and at least 80% spectrum overlap with the first excited light. . Example three

Embodiment 3

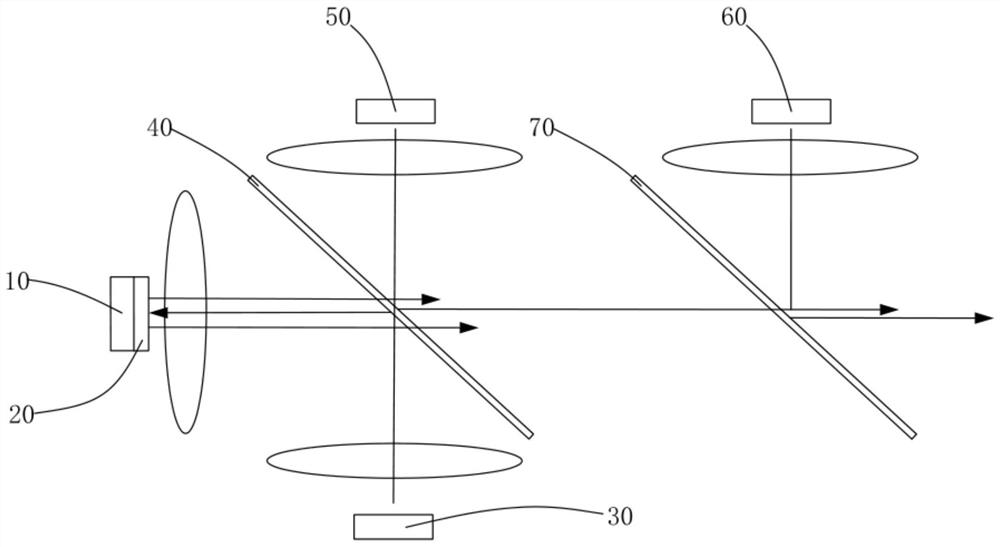

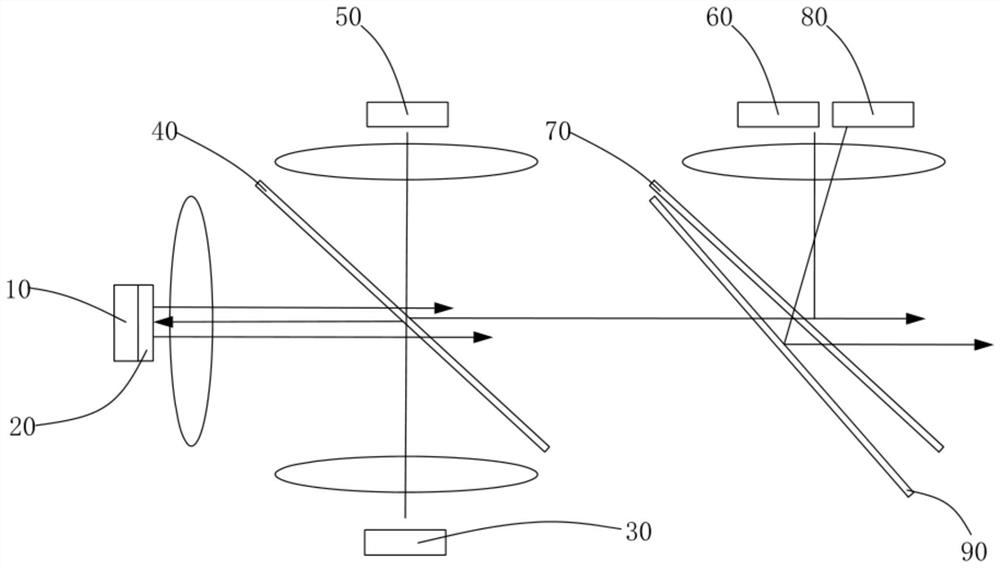

[0066] In one embodiment of the invention, please refer to figure 2 The multi-channel optical architecture of the high brightness also includes a third solid state light-emitting chip 60 and a second engaging light filter 70; the third solid light-emitting chip 60 is used to transmit the third spectrum, the third spectrum of light can For green light, it is protected green or blue; if the light of the second spectrum is blue, the light of the third spectrum is green or excited green. If the light of the second spectrum is green, then the third spectrum Light is blue; wherein the first spectrum of light, the first excited light, the second spectrum of light, and the third spectrum of light are photographed by the first plexamethum filter 40 and the The second engaged light filter 70 is combined into the coaxial light, without increasing the optical expand, constitutes a multi-channel architecture of high brightness, wider color gamut, and small light energy, no evaporation of hairl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com