Block-assembled capillary heat exchanger and assembling method thereof

A capillary tube and heat exchanger technology, applied in the field of block-type assembled capillary tube heat exchanger and its assembly, can solve the problems of small tube diameter, cumbersome, complicated operation, etc., so as to improve welding efficiency, reduce maintenance work, and improve wear and tear. The effect of tube efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

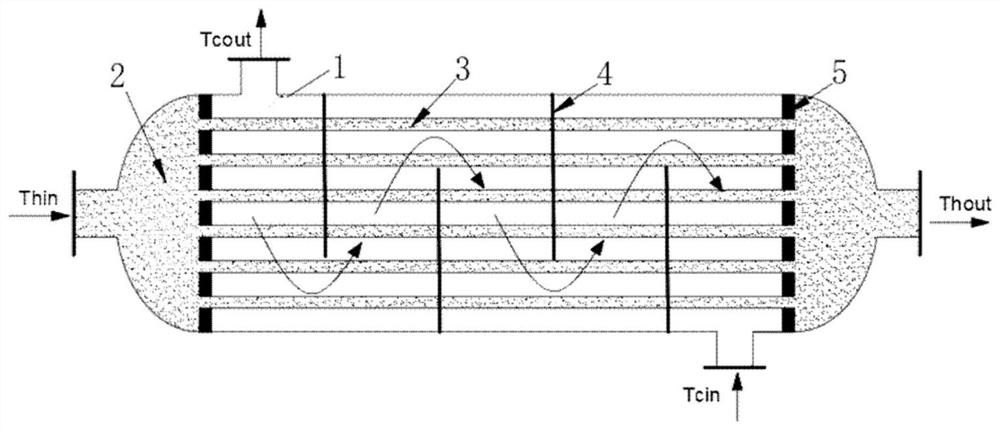

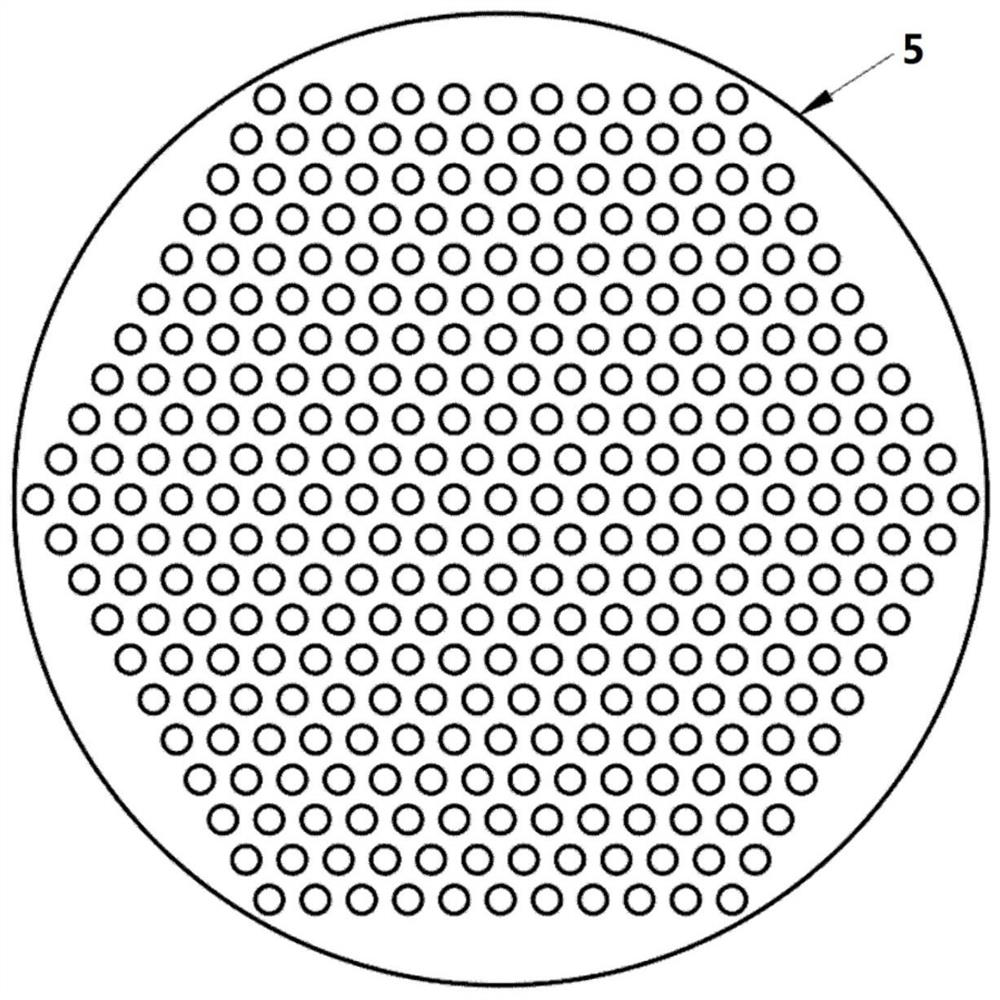

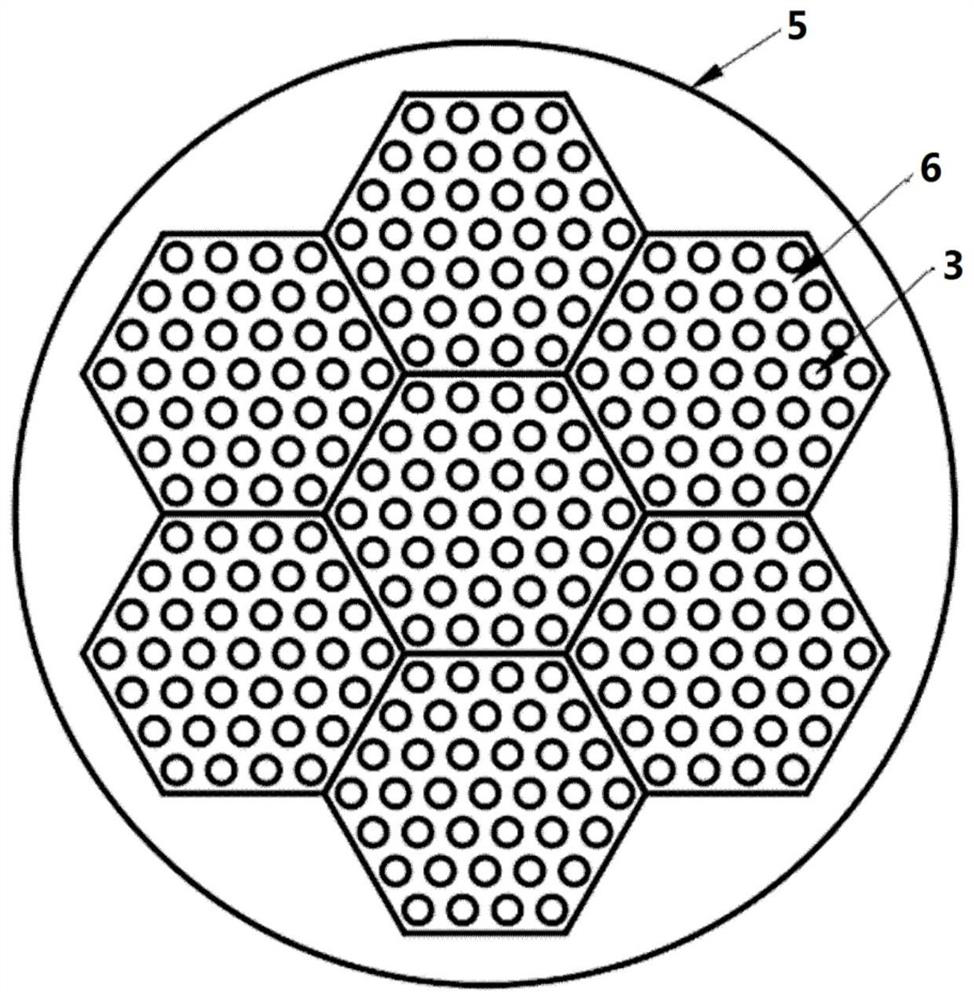

[0028] The present invention provides a capillary tube heat exchanger assembled in blocks. The capillary tube heat exchanger includes: a shell 1 , a tube box space 2 , a heat transfer tube 3 , a baffle plate 4 , and a tube plate 5 .

[0029] figure 1 Schematic diagram of the capillary heat exchanger.

[0030] like figure 1 As shown, the capillary heat exchanger includes: a shell 1, a tube box space 2 is formed inside, a first fluid inlet Thin and a first fluid output Thout are arranged at both ends of the shell 1, and on the shell 1 The other two ends are provided with a second fluid inlet Tcin and a second fluid outlet Tcout; a plurality of heat transfer tubes 3 are arranged in the tube box space 2 and communicate with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com