Load port flow pulse independent control digital hydraulic servo system and control method

A pulse digital, hydraulic servo technology, applied in fluid pressure actuation system testing, fluid pressure actuation system components, servo motors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

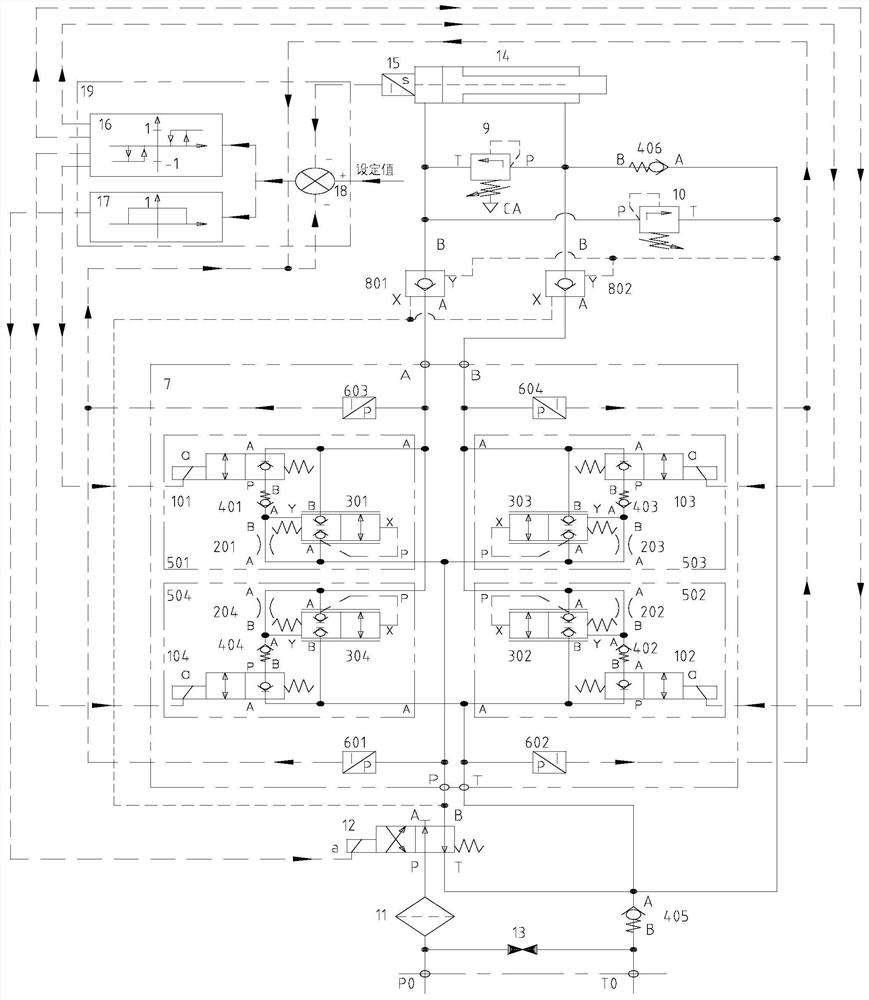

[0029] Such as figure 1 As shown, in this embodiment, a digital hydraulic servo system based on a high-frequency stepless speed regulation intelligent digital valve independently controls the load port flow pulse, including a high frequency response stepless speed regulation intelligent digital valve 7, a hydraulic cylinder 14, and an electrical control system. Device 19 and control valve; the specific structure is:

[0030] The main pressure pipeline P0 is connected to the oil port P of the solenoid valve 12 through the filter 11; the oil port B of the solenoid valve 12 is connected to the oil port P of the high-frequency stepless speed regulation intelligent digital valve 7; the main oil return line T0 is respectively connected to the oil port T of the solenoid valve 12 and the oil port T of the high-frequency stepless speed regulation intelligent digital valve 7 through the oil port B of the fifth one-way valve 405 through the oil port A; the main pressure pipeline P0 passe...

Embodiment 2

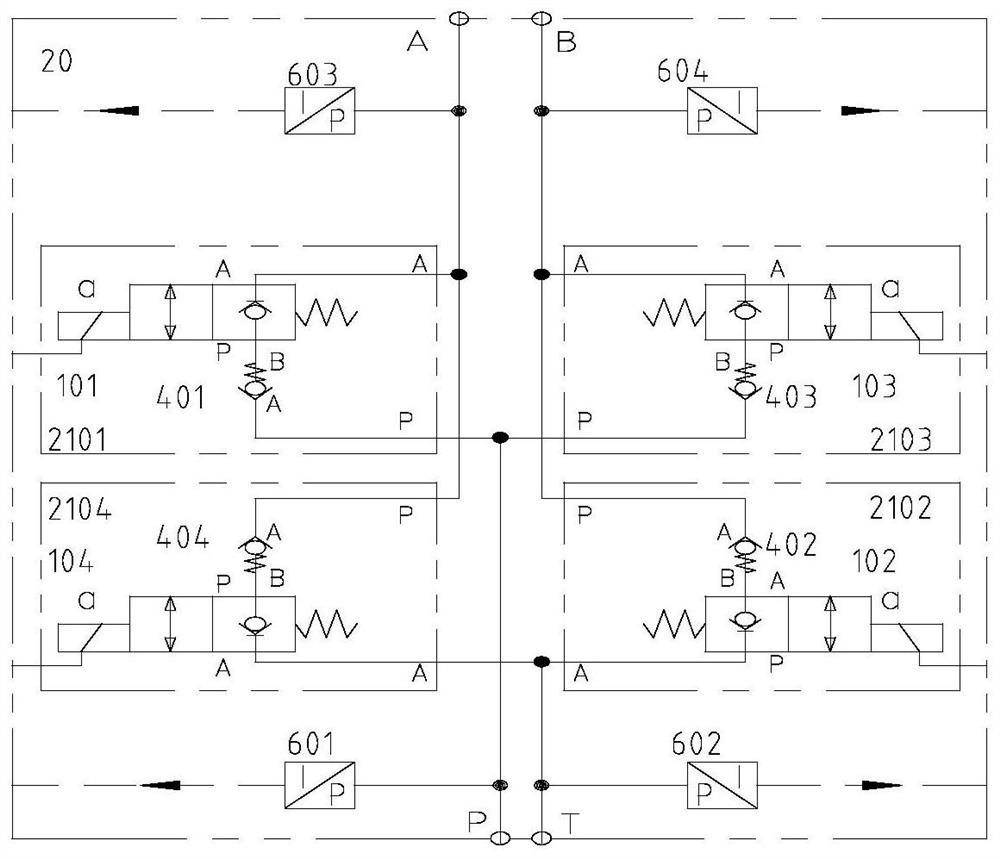

[0054] Such as figure 2 As shown, it is another embodiment of the present invention. The first embodiment is the intelligent control technology and automatic fault diagnosis method of the load port flow pulse independent control of the high pollution resistance digital hydraulic servo system with high frequency response speed stepless adjustment, The high-frequency response speed stepless adjustment function of the hydraulic cylinder 14 is realized. figure 2 The second embodiment is an independent control of flow pulse at the load port with high frequency response and low speed operation, high pollution resistance digital hydraulic servo system intelligent control technology and automatic fault diagnosis method, because there is no large flow control of proportional flow valve, it is especially suitable for In the case of low-speed control of the hydraulic cylinder 14, the low-speed intelligent control and fault automatic diagnosis functions of the hydraulic cylinder 14 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com