A split-flow cooled aeroengine compressor rear shaft diameter tapered wall cavity

A technology of aero-engines and compressors, which is applied in the direction of machines/engines, liquid fuel engines, and parts of pumping devices for elastic fluids, etc. It can solve the problem of failure to achieve reasonable distribution and utilization of airflow, failure to achieve cooling effects, etc. problems, to achieve the effect of reducing wind resistance, improving cooling quality, and precise cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only for illustration and are not intended to limit the present invention.

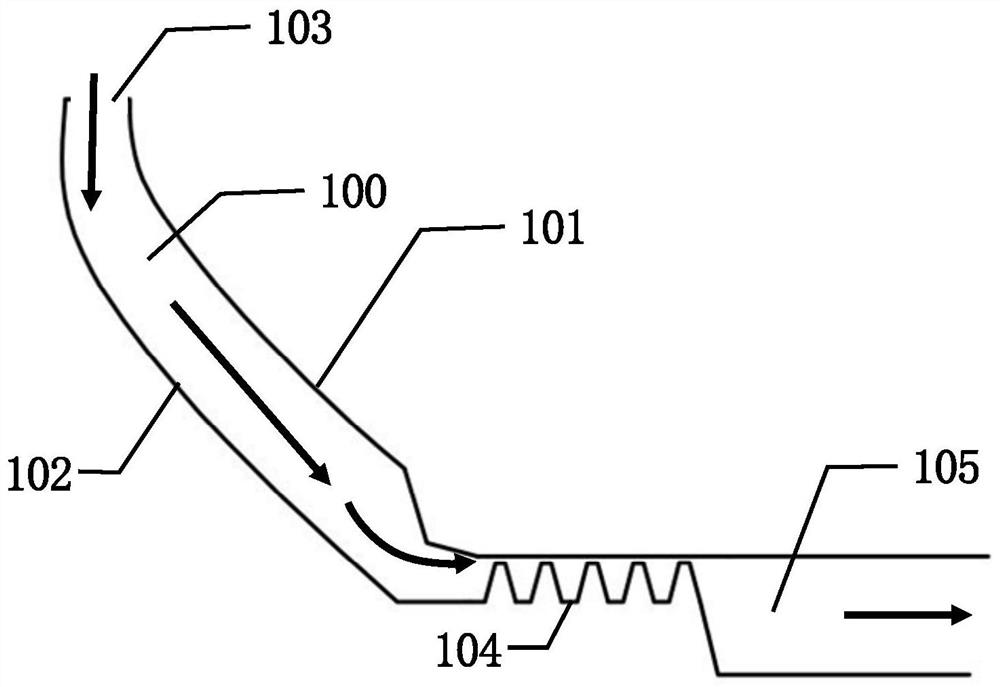

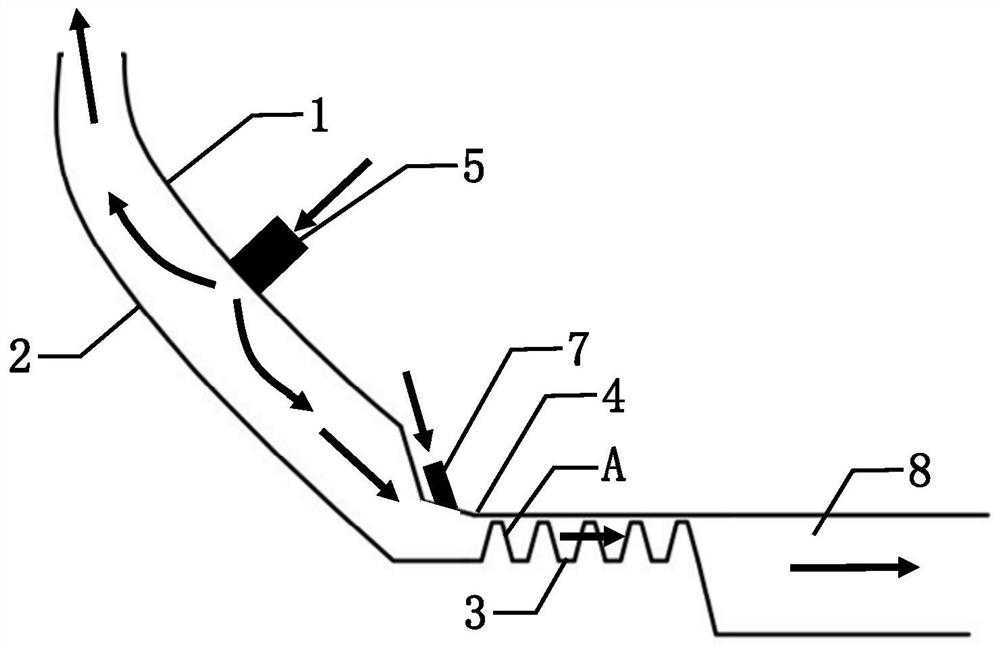

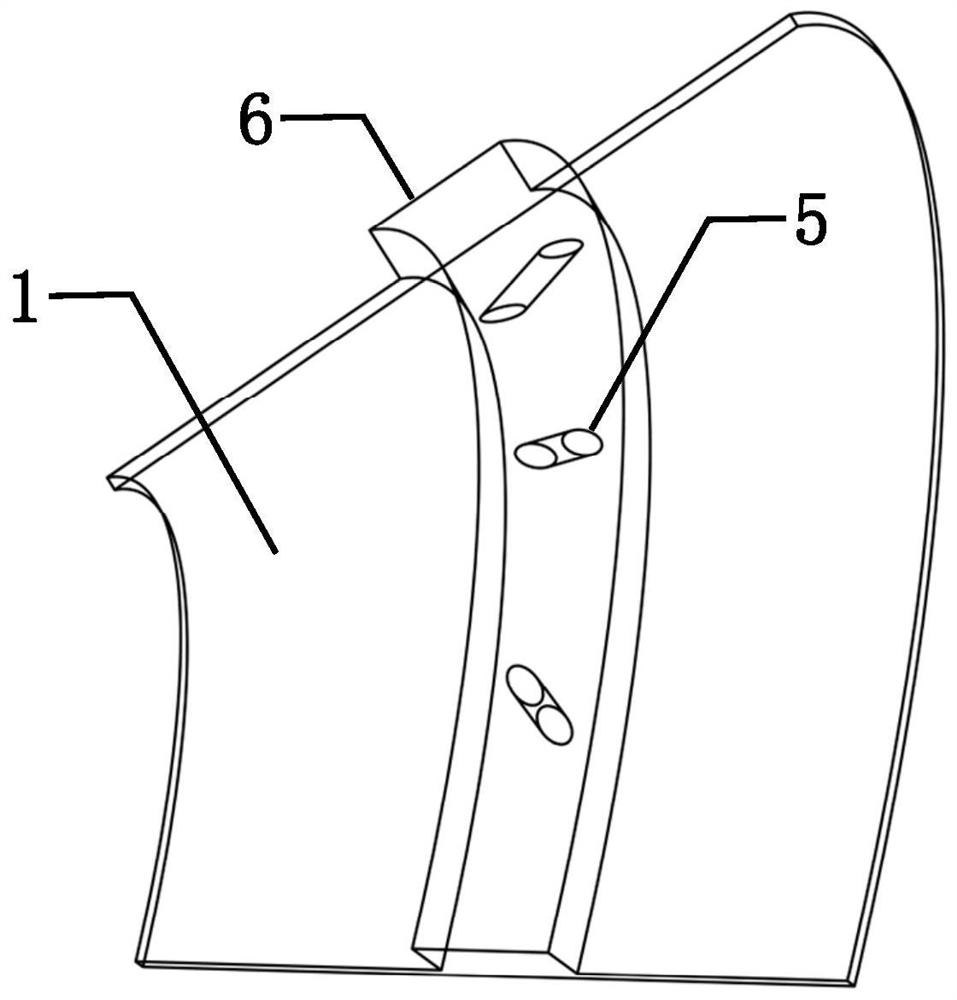

[0026] The invention provides a split-cooled aero-engine compressor rear shaft diameter tapered wall cavity, such as figure 2 As shown, it is formed by the stator cone surface 1, the rotor cone surface 2 opposite to the stator cone surface 1, the grate element 3 and the stator drum surface 4 opposite to the grate element 3;

[0027] In the middle position along the height direction of the stator cone surface 1, within the range of upward and downward deviations of 10mm respectively, a circle of first bosses are provided along the circumference of the stator cone surface 1, and a plurality of first pre-rotation platforms are arranged on the first bosses...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com