A turbine outer ring block air supply structure with separate chamber air supply

A cavity-dividing and turbine technology, applied in the directions of blade support elements, machines/engines, and mechanical equipment, can solve the problem of reduced intake and exhaust pressure, large axial pressure gradient at the outlet of the outer ring block, and excessive cooling of the outer ring block. Loss and other problems, to achieve the effect of enhancing the cooling effect and reducing the increase in the air bleed volume of the air system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

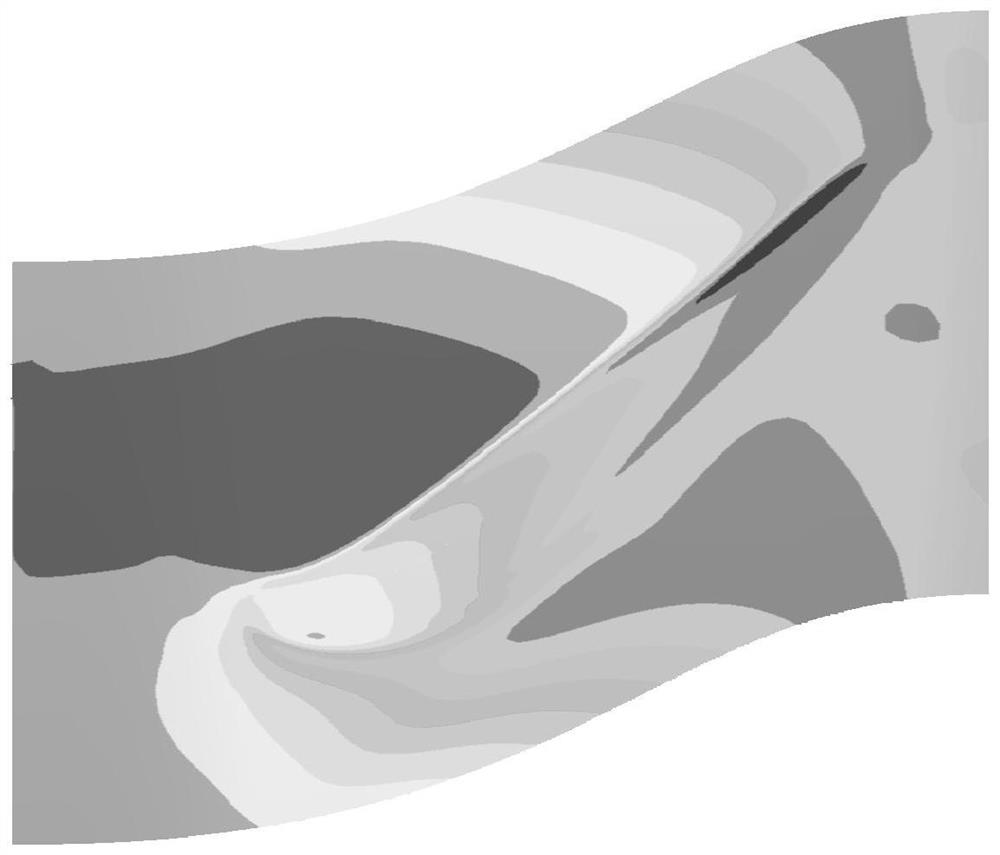

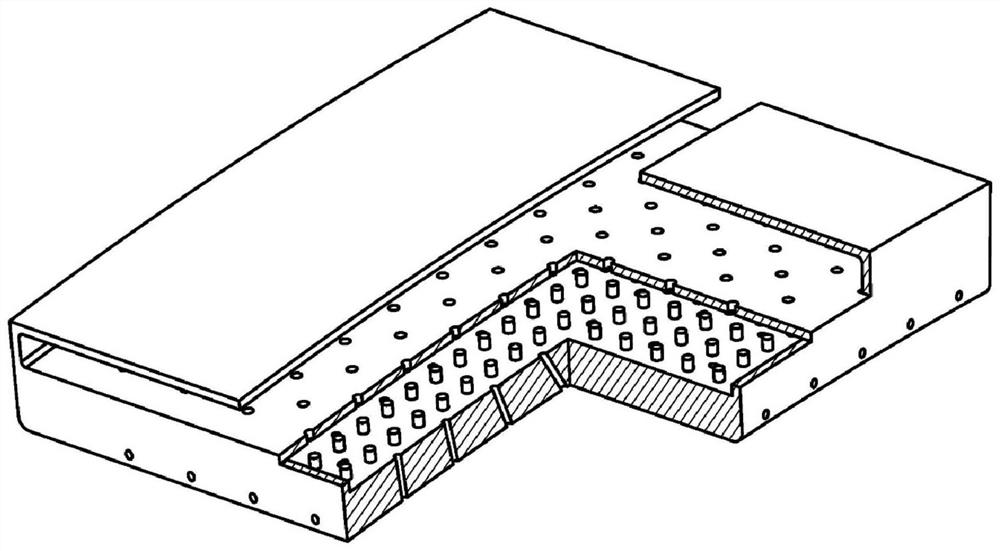

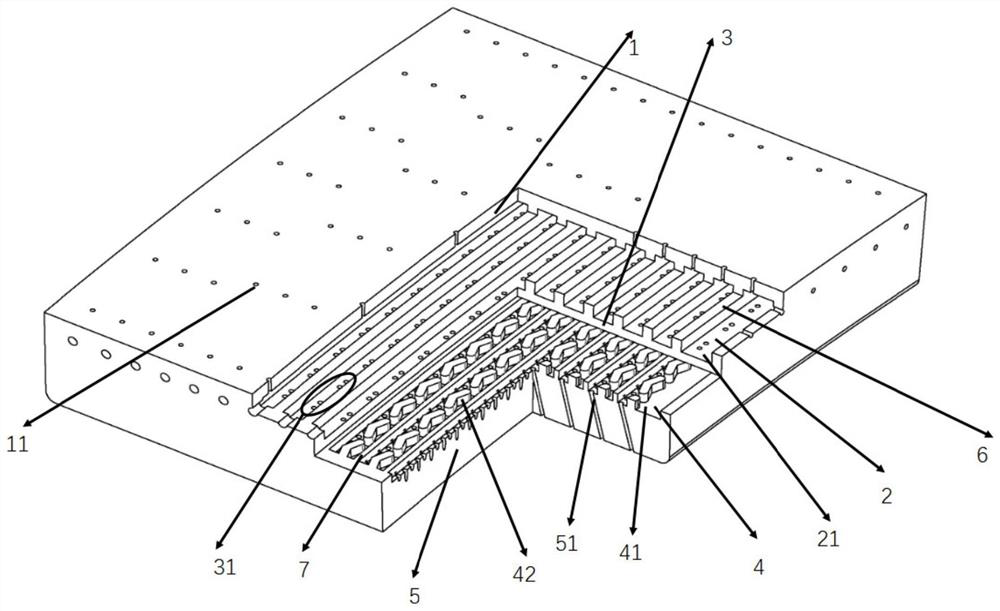

[0025] The present invention adds a layer of throttling cavity between the air supply cavity and the impingement cavity of the outer ring block of the turbine, and divides the throttle cavity into a plurality of independent composite cooling throttling sub-cavities along the axial direction of the turbine. Corresponding to the cavity, the impact cavity of composite cooling is also divided into multiple independent impact sub-cavities along the axial direction of the turbine, so that the entire outer ring block is divided into multiple cooling units that do not interfere with each other along the axial direction of the turbine, avoiding the impact caused by a single impact cavity The resulting problem that the outer ring block is poor before cooling and then rich after cooling has formed a targeted cooling structure, which improves the utilization rate of cold air, and then improves the engine performance under the premise of the same temperature before the turbine.

[0026] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com