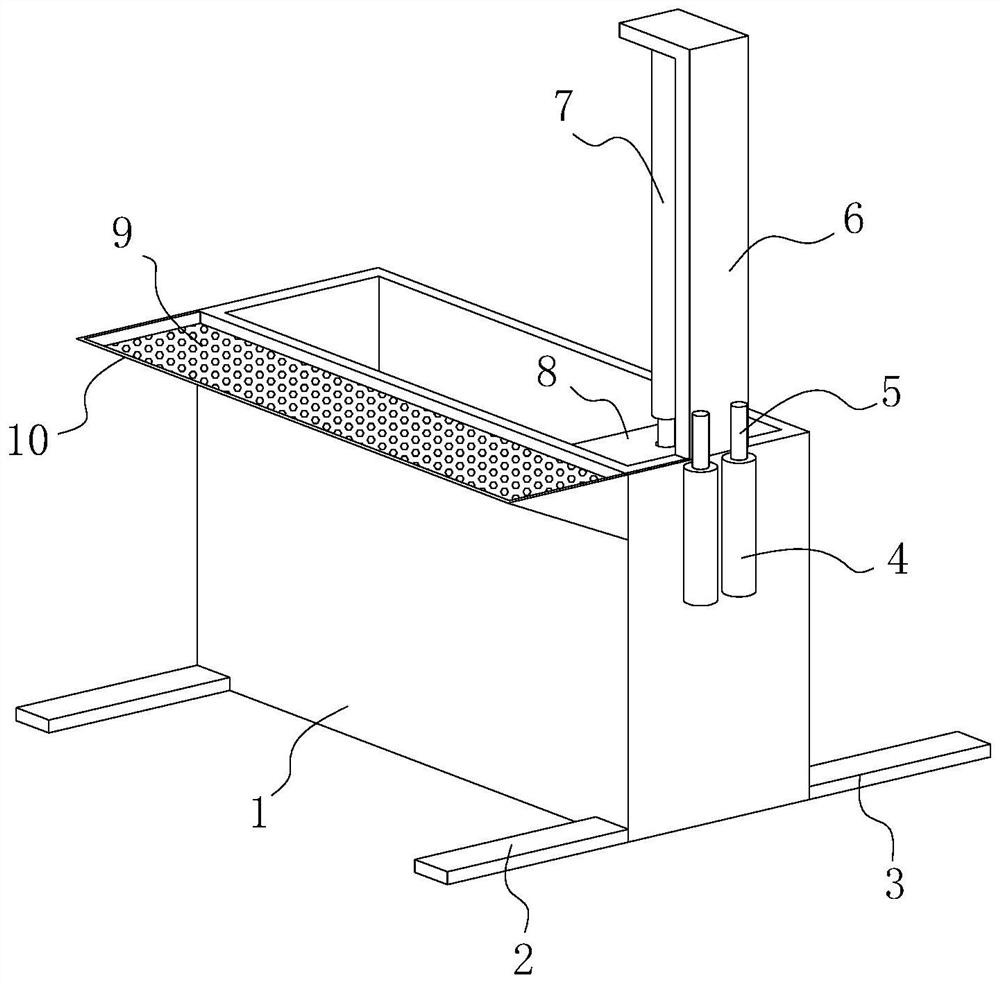

Novel textile dyeing device

A dyeing device and a new type of technology are applied in the processing of textile material equipment configuration, textile and papermaking, and textile material processing. It can solve problems such as corrosion of electric push rods, affecting the service life of electric push rods, and achieve the effect of stabilizing dye liquor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

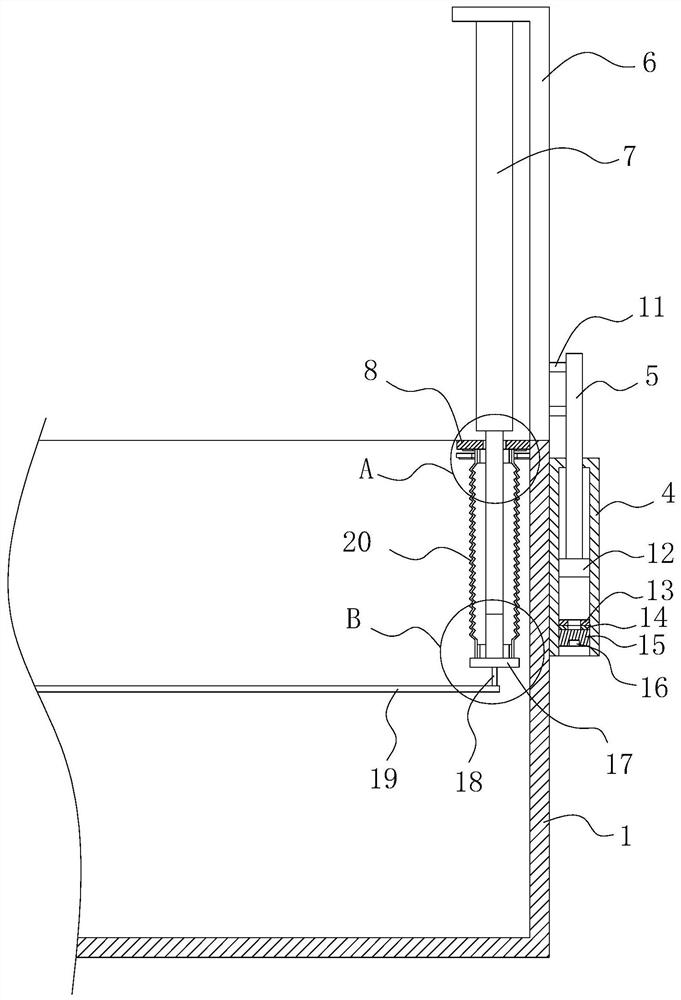

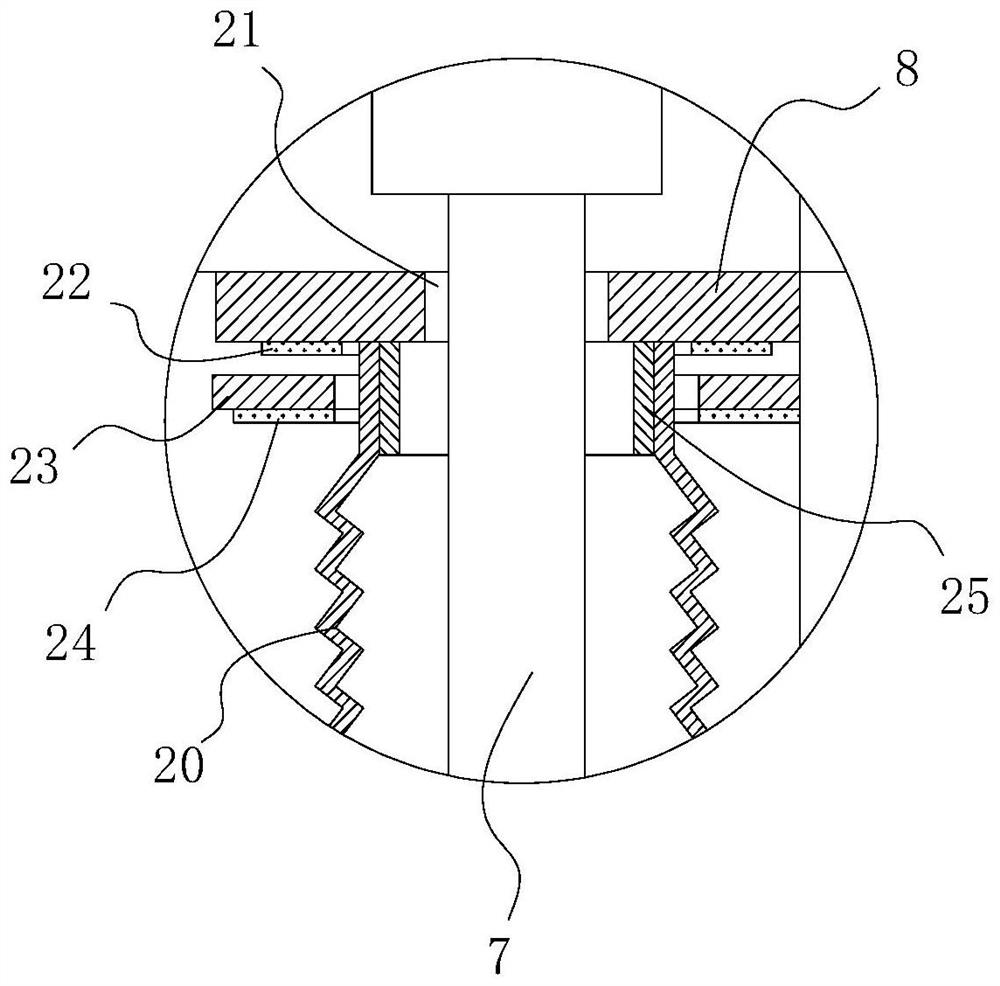

[0039] Specific implementation method: the bellows 20 is sleeved on the movable end of the electric push rod 7, and the two ends of the bellows 20 are fixedly connected with the isolation plate 8 and the bottom plate 17 respectively, so that when the electric push rod 7 is extended, the bellows 20 Elongation, when the electric push rod 7 shrinks, the bellows 20 shortens, and then under the cover of the bellows 20, the dye solution in the anti-dye tank 1 contacts with the electric push rod 7 at will, which plays the role of protecting the electric push rod 7.

[0040] When the dye liquor in the dye tank 1 shakes, the blocking ring 23 and the isolation plate 8 work together to stabilize the dye liquor, and prevent the dye liquor around the electric push rod 7 from splashing due to excessive shaking, while the first sponge The ring 22 and the second sponge ring 24 further reduce the shaking amplitude of the dye solution, and improve the effect of preventing the dye solution from s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com