Preparation method for graphene/titanium-based nanocomposite without interface reaction

A nanocomposite material and graphene technology, which is applied in the field of graphene/titanium-based nanocomposite preparation, to achieve the effects of inhibiting the growth of grains, refining matrix grains, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

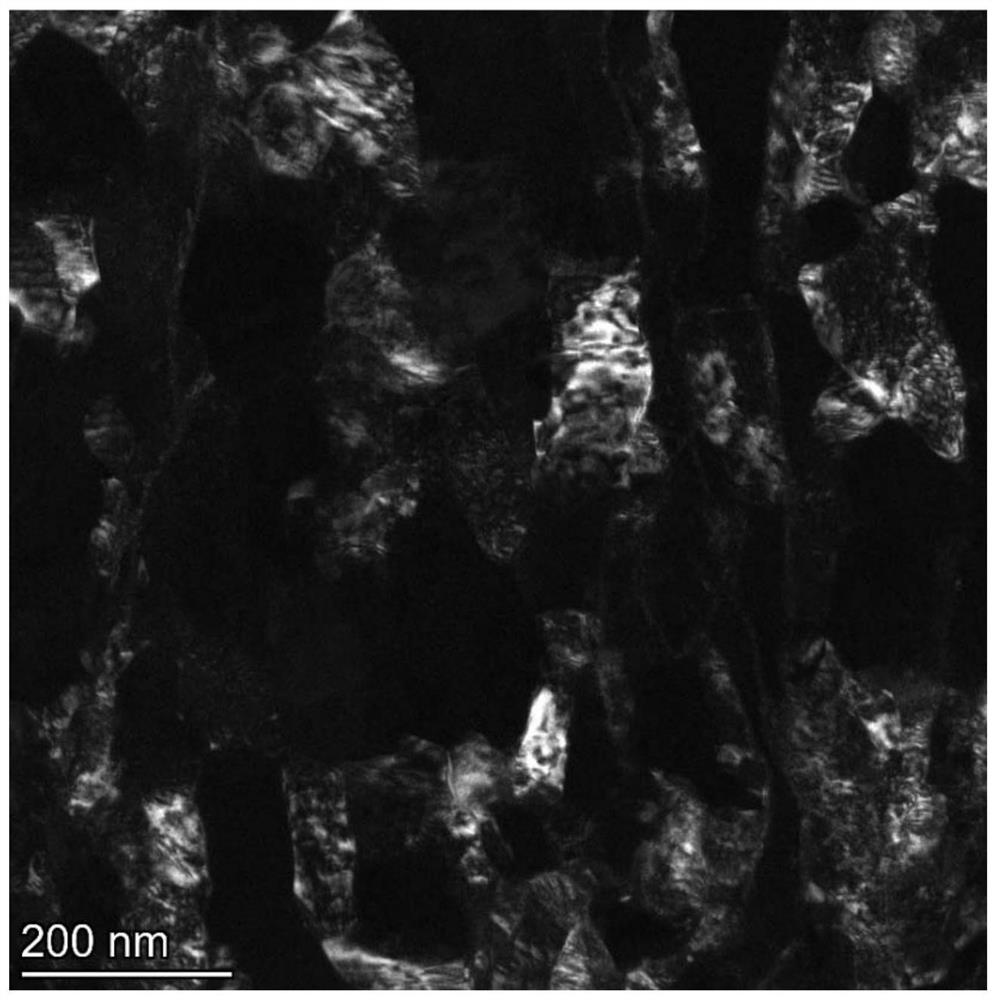

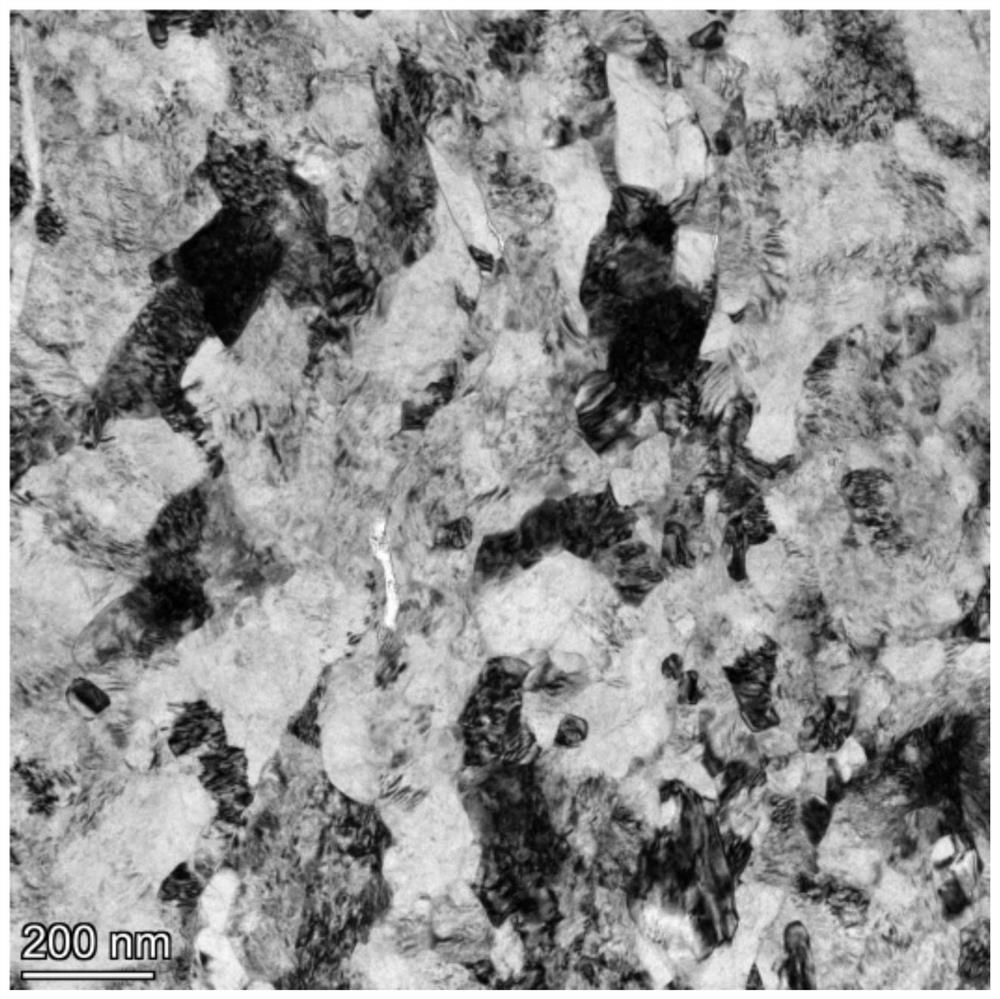

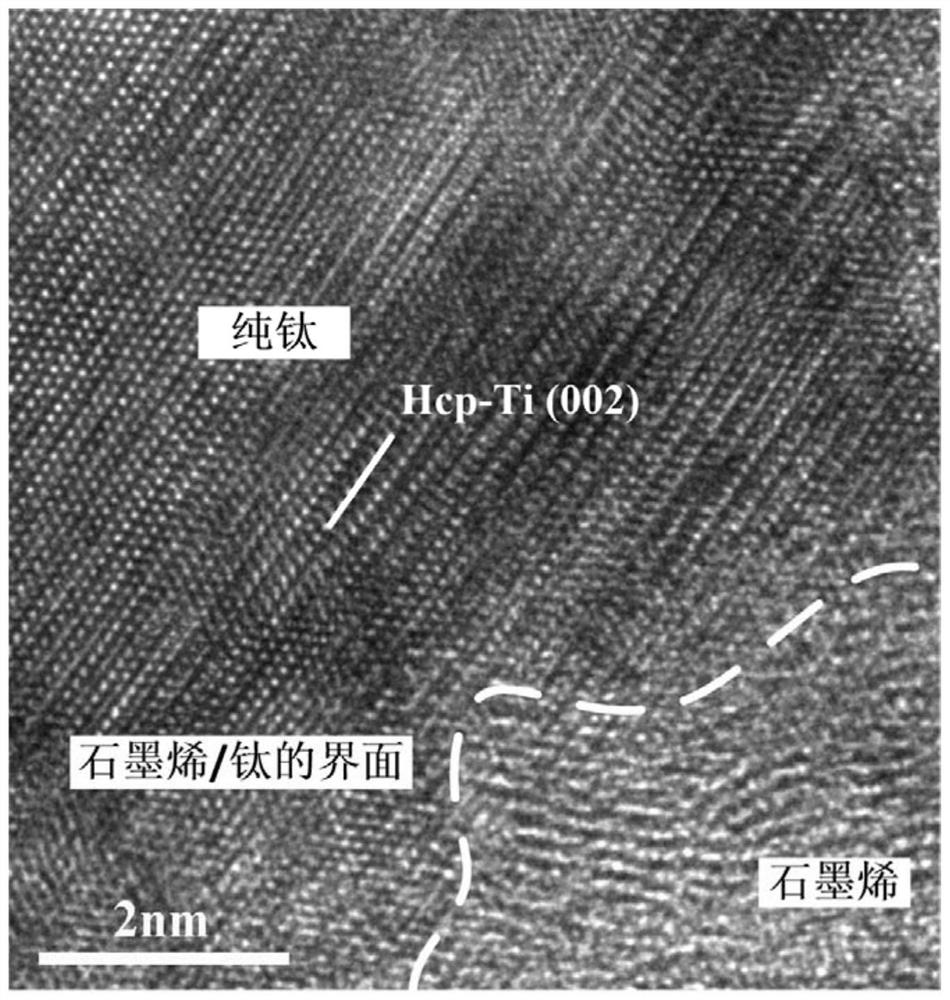

Image

Examples

Embodiment 1

[0059] The specific preparation steps of the graphene / titanium-based nanocomposite without interfacial reaction are as follows:

[0060] (1) Add 0.018g graphene and 0.018g sodium dodecylbenzenesulfonate (SDS) into 100mL absolute ethanol, and ultrasonically disperse at 100W power for 0.5h; then add 3g pure titanium powder, and adjust the ultrasonic power to 300W, and then continue to ultrasonically disperse for 0.5h; transfer the mixed slurry to a rotary evaporator, remove absolute ethanol by rotary evaporation at 30r / min and 70°C, and then transfer to a vacuum oven at 50°C to dry for 12h to obtain Dry mixed powder;

[0061] (2) First place a stainless steel sheath with an inner diameter of 14mm, an outer diameter of 16mm, and a height of 2.5mm at 1000°C for annealing treatment for 1 hour, then put the mixed powder into the sheath and use a pressure of 5GPa to seal the inside of the sheath The mixed powder is pre-pressed into a round cake body with a diameter of 14mm and a thi...

Embodiment 2

[0068] The specific preparation steps of the graphene / titanium-based nanocomposite without interfacial reaction are as follows:

[0069] (1) Add 0.018g of graphene and 0.018g of sodium dodecylbenzenesulfonate into 150mL of absolute ethanol, ultrasonically disperse at 100W power for 1h; then add 3g of pure titanium powder, and adjust the ultrasonic power to 300W, then Continue ultrasonic dispersion for 1 hour; transfer the mixed slurry to a rotary evaporator, remove absolute ethanol by rotary evaporation at 30r / min and 80°C, then transfer to a vacuum oven at 60°C for 12 hours to obtain a dry mixed powder ;

[0070] (2) First anneal the stainless steel sheath with an inner diameter of 10mm, an outer diameter of 12mm and a height of 2mm at 1000°C for 1h, then put the mixed powder into the sheath and use the pressure of 3GPa to put the mixed powder in the sheath The body is pre-pressed into a round cake body with a diameter of 10mm and a thickness of 2mm, and then the package is ...

Embodiment 3

[0076] The specific preparation steps of the graphene / titanium-based nanocomposite without interfacial reaction are as follows:

[0077] (1) Add 0.036g of graphene and 0.036g of sodium dodecylbenzenesulfonate into 200mL of absolute ethanol, ultrasonically disperse at 100W power for 1h; then add 3g of pure titanium powder, and adjust the ultrasonic power to 600W, then Continue ultrasonic dispersion for 1 hour; transfer the mixed slurry to a rotary evaporator, remove absolute ethanol by rotary evaporation at 30r / min and 80°C, then transfer to a vacuum oven at 60°C for 12 hours to obtain a dry mixed powder ;

[0078] (2) First place a stainless steel sheath with an inner diameter of 14mm, an outer diameter of 16mm, and a height of 2mm at 1050°C for 0.5h for annealing treatment, then put the mixed powder into the sheath and use a pressure of 4GPa to seal the inside of the sheath The mixed powder is pre-pressed into a round cake body with a diameter of 14mm and a thickness of 2mm,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com