A kind of high-solid polyurethane ink resin, preparation method and application thereof

A technology of ink resin and polyurethane, applied in the direction of polyurea/polyurethane coating, ink, application, etc., can solve the problems of loss of usability, high viscosity, etc., and achieve the effect of enhancing affinity and excellent application performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A preparation method of high-solid polyurethane ink resin, comprising the following steps:

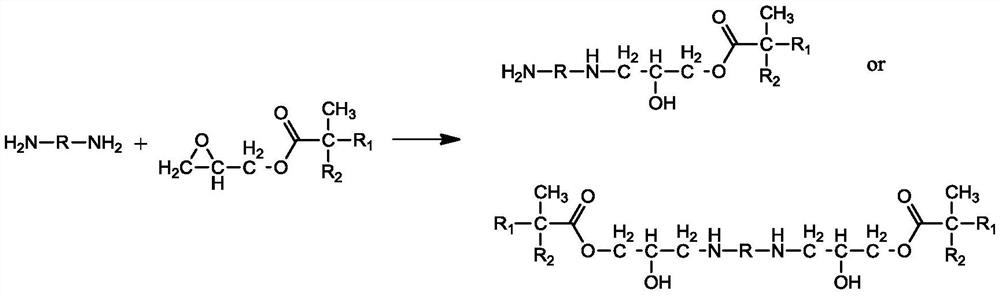

[0034] 1) Preparation of functional amine chain extender E: put amine chain extender and solvent isopropanol into the flask, stir evenly at room temperature, add glycidyl tertiary carbonate dropwise to it, drip it for 0.5 to 1 hour, then The temperature is raised to 55 to 65° C. and the reaction is stirred for 4 to 6 hours to obtain a functional amine chain extender E, which is kept for later use.

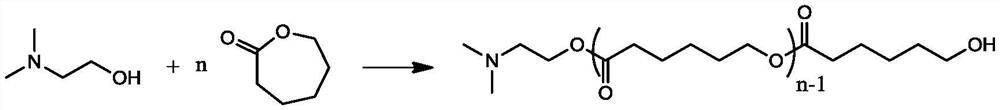

[0035] 2) Preparation of functional end-capping agent T: put monohydroxy tertiary amine, lactone and catalyst tetrabutyl titanate in a flask, pass nitrogen, stir evenly, heat up to 140-160 ° C and react for 24-36 hours to obtain functional Type end capping agent T, keep it for later use.

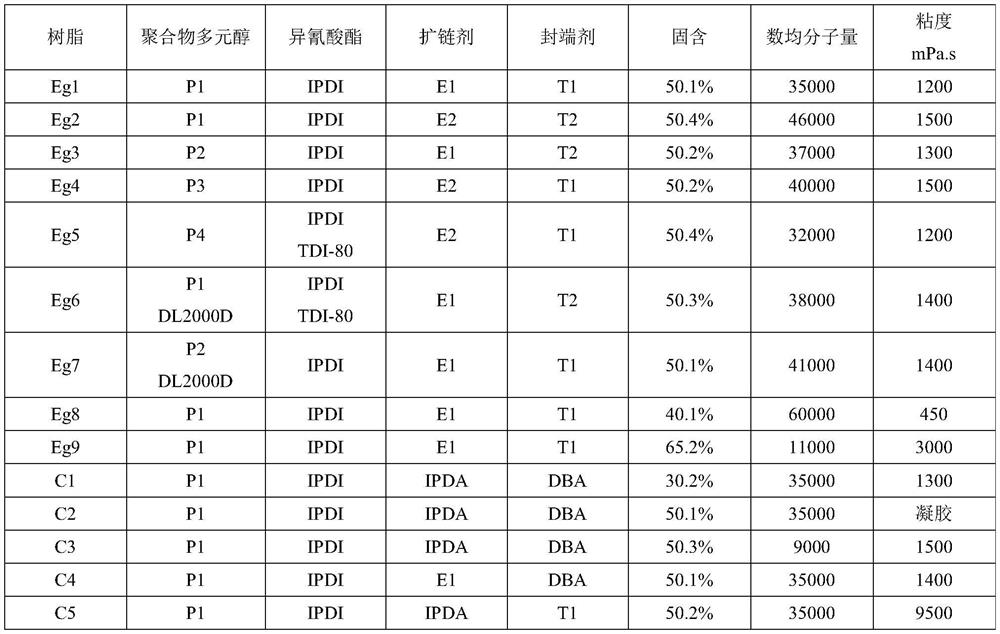

[0036] 3) Put the polymer polyol, polyisocyanate, catalyst and part of the solvent into the flask, pass nitrogen, react at 60~120°C for 3~5 hours, add functional end capping agent T, and continue ...

preparation example E1

[0079] Put 50g IPDA and 83.53g solvent IPA into the flask, stir evenly at room temperature, add 33.53g of glycidyl tertiary carbonate E10P dropwise to it, drop it in 0.5 hours, then be heated to 60 ° C and stir for 5 hours to obtain the functional type Amine chain extender E1, molecular weight 284.42, solid content 50%.

preparation example E2

[0081] Put 50g HDA and 108.96g solvent IPA into the flask, stir evenly at room temperature, add 58.96g of glycidyl tertiary carbonate E10P dropwise to it, drop it in 0.5 hours, then heat up to 60°C and stir for 5 hours to prepare the functional type Amine chain extender E1, molecular weight 253.22, solid content 50%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com