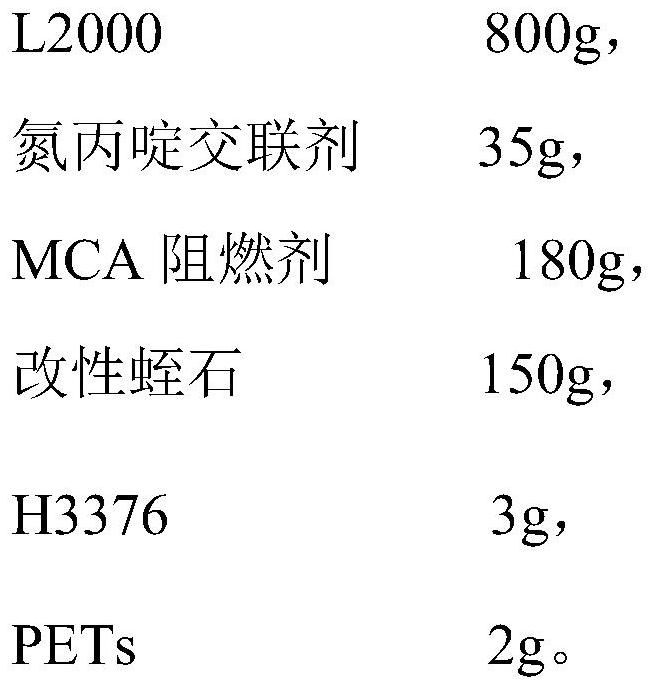

Halogen-free flame-retardant solvent-resistant PA12 material and preparation method thereof

A solvent-resistant and flame-retardant technology, applied in the field of halogen-free flame-retardant and solvent-resistant PA12 materials and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

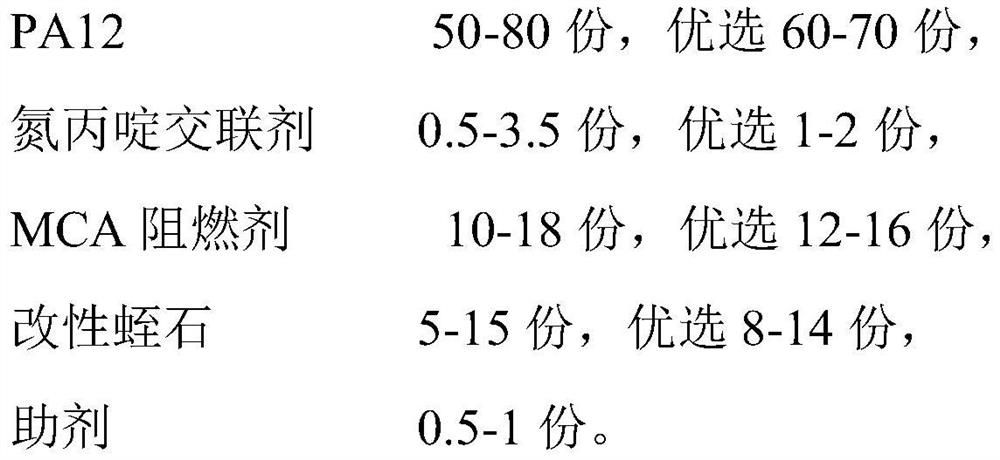

[0051] Prepare the ingredients according to the following recipe:

[0052]

[0053] Prepare PA12 material according to the following method:

[0054] (1) Prepare modified vermiculite:

[0055] Add 40g of vermiculite to 1200ml of hydrochloric acid, stir and reflux at 40°C for 18h, filter and wash the solid repeatedly until the supernatant has pH ≈ 7, and dry the solid in an oven at 90°C for 16h to obtain acidified vermiculite;

[0056] Take 50g of acidified vermiculite and 10g of toughening agent GR216 in 1800ml of toluene, heat and stir in a reflux device at 40°C for 5h, take out the reactant and wash it by centrifugation; take the centrifuge and wash it with acetone, toluene, and ethanol in sequence. Finally, it is washed with water, and the obtained product is dried in an oven at 90° C. to obtain modified vermiculite.

[0057] (2) Weigh 500g of L1000 and 2.5g of aziridine cross-linking agent respectively, place them in a high mixer at 60°C and mix for 3 minutes, then ad...

Embodiment 2

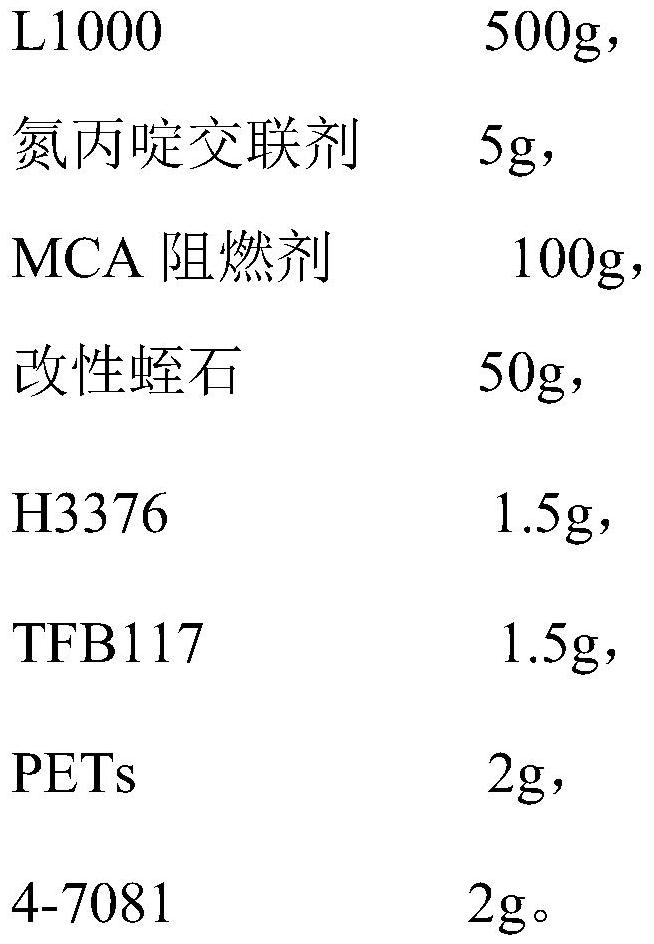

[0060] Prepare the ingredients according to the following recipe:

[0061]

[0062] Prepare PA12 material according to the following method:

[0063] (1) Prepare modified vermiculite:

[0064] Add 40g of vermiculite to 1200ml of hydrochloric acid, stir and reflux at 80°C for 10h, filter and wash the solid repeatedly until the supernatant has pH ≈ 7, and dry the solid in an oven at 100°C for 48h to obtain acidified vermiculite;

[0065] Take 60g of acidified vermiculite and 30g of toughening agent N416 in 4500ml of toluene, heat and stir in a reflux device at 60°C for 3h, take out the reactant and wash it by centrifugation; take the centrifuge and wash it with acetone, toluene, and ethanol in sequence, Finally, it is washed with water, and the obtained product is dried in an oven at 100° C. to obtain modified vermiculite.

[0066] (2) Weigh 800g of L2000 and 18g of aziridine cross-linking agent respectively, place them in a high mixer at 45°C and mix for 8 minutes, then ad...

Embodiment 3

[0069] Prepare the ingredients according to the following recipe:

[0070]

[0071] Prepare PA12 material according to the following method:

[0072] (1) Prepare modified vermiculite:

[0073] Add 40g of vermiculite to 1600ml of hydrochloric acid, stir and reflux at 50°C for 15h, filter and wash the solid repeatedly until the supernatant has pH ≈ 7, and dry the solid in an oven at 95°C for 24h to obtain acidified vermiculite;

[0074] Take 60g of acidified vermiculite and 20g of toughening agent N416 in 3200ml of toluene, heat and stir in a reflux device at 45°C for 6h, take out the reactant and wash it by centrifugation; take the centrifuge and wash it with acetone, toluene, and ethanol in sequence, Finally, it is washed with water, and the obtained product is dried in an oven at 95° C. to obtain modified vermiculite.

[0075] (2) Weigh 300g of L1000, 300g of L2000, and 3g of aziridine cross-linking agent, place them in a high mixer at 50°C and mix for 5 minutes, then ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com