Clay-resistant phosphonic acid-based super plasticizer and preparation method thereof

A superplasticizer and phosphonic acid-based technology, which is applied in the field of clay-resistant phosphonic acid-based superplasticizer and its preparation, can solve the problems of unoptimistic market prospects and high production costs, and achieve a simple and efficient synthesis process and low cost. , The effect of good adsorption and dispersion performance and water reduction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

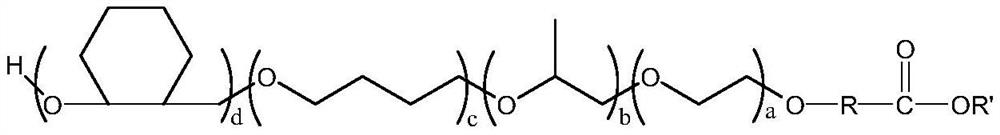

[0056] For the esterified polyether, the synthesis initiator is methyl glycolate, the polymerized monomer is ethylene oxide, the concentration of the catalyst DMC is 30 ppm, and the amount of cocatalyst benzoic acid added is 0.1% of the mass of the methyl glycolate. Weigh 1 mol (90 g) of methyl glycolate, 20 mol (880 g) of ethylene oxide, 29 mg of catalyst DMC and 0.12 g of cocatalyst benzoic acid. Add the above-mentioned initiator methyl glycolate and catalyst into a closed reaction kettle, vacuumize to -0.1MPa, feed 20g of ethylene oxide, raise the temperature to 120°C to initiate the reaction and continue feeding the remaining ethylene oxide, keep warm After reacting for 1 hour, the volatile matter was removed under reduced pressure, and the insoluble matter was removed by filtration to obtain a carboxylate-modified polyether intermediate.

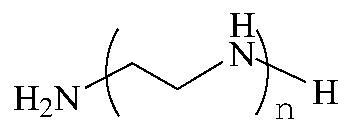

[0057] Add 1.01mol (60.7g) of ethylenediamine into the above reaction kettle containing carboxylate-modified polyether intermediate, s...

Embodiment 2

[0059] Esterified polyether, the synthesis initiator is ethyl glycolate, the polymerized monomers are ethylene oxide and propylene oxide, the concentration of catalyst DMC is 40ppm, and the addition of co-catalyst benzoic acid is 0.2% of the mass of ethyl glycolate. %. Weigh 1 mol (104 g) of ethyl glycolate, 25 mol (1100 g) of ethylene oxide, 20 mol (1160 g) of propylene oxide, 95 mg of catalyst DMC and 0.24 g of cocatalyst benzoic acid. Add the above-mentioned initiator ethyl glycolate and catalyst into a closed reaction kettle, evacuate to -0.1MPa, feed 20g of ethylene oxide, raise the temperature to 120°C to initiate the reaction, and continue to feed the remaining ethylene oxide and Propylene oxide, keep warm for 3 hours, remove volatile substances under reduced pressure, and remove insoluble substances by filtration to obtain a carboxylate-modified polyether intermediate.

[0060] Add 1.01mol (104.2g) of diethylenetriamine into the above-mentioned reaction kettle contain...

Embodiment 3

[0062] Esterified polyether, the synthesis initiator is methyl 3-hydroxypropionate, the polymerized monomers are ethylene oxide and cyclohexane oxide, the concentration of catalyst DMC is 40ppm, and the addition amount of co-catalyst benzoic acid is 3-hydroxy 0.3% of the mass of methyl propionate. Weigh 1 mol (104 g) of methyl 3-hydroxypropionate, 40 mol (1760 g) of ethylene oxide, 10 mol (981 g) of cyclohexane oxide, 114 mg of catalyst DMC and 0.36 g of cocatalyst benzoic acid. Add the above-mentioned initiator 3-hydroxypropionate methyl ester and the catalyst into the closed reaction kettle, vacuumize to -0.1MPa, pass in 20g of ethylene oxide, raise the temperature to 130°C to initiate the reaction and continue to pass in the remaining epoxy Ethane and epoxycyclohexane, heat preservation reaction for 3 hours, remove volatile substances under reduced pressure, and remove insoluble substances by filtration to obtain carboxylate modified polyether intermediate.

[0063] Add 1....

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com