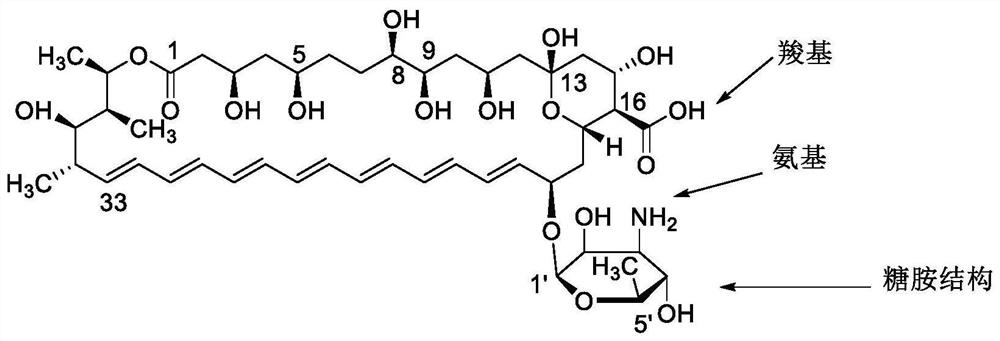

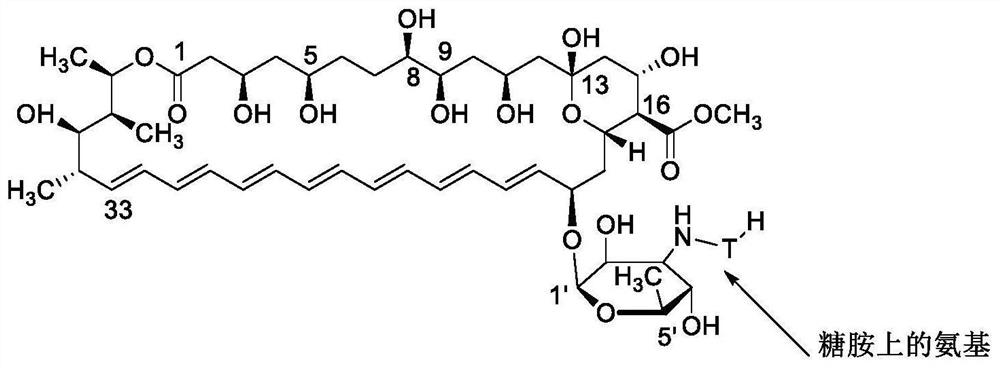

Amphotericin B methyl ester peptide derivative and preparation method thereof

A technology of derivatives and methyl groups, applied in the field of amphotericin B methyl esterified peptide derivatives and their synthesis and preparation, can solve the problems of liposome instability, increased therapeutic dose, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

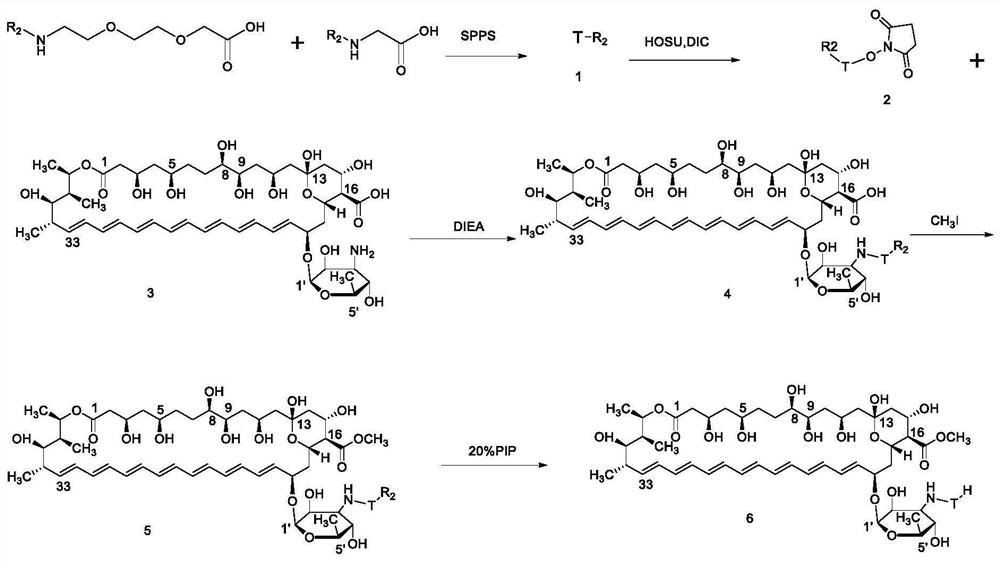

Method used

Image

Examples

Embodiment 1

[0181] Example 1: Preparation and purification of DMR005-JZH

[0182] Hydrophilic peptide structure: Fmoc-AEEAc-AEEAc-AEEAc-AEEAc–AEEAc-OH

[0183] DMR005-JZH structure:

[0184]

[0185] (1) Materials and reagents

[0186] 2-CTC resin, substitution value 0.945mmol / g.

[0187] The amino acid is: Fmoc-AEEAc-OH

[0188] Synthetic reagents: HATU, DMF, DCM, DIEA, piperidine, methyl iodide.

[0189] (2) Instrument

[0190] CS-BIO peptide synthesizer, Waters600 semi-preparative high performance liquid chromatography, Beckman centrifuge, Buchi rotary evaporator.

[0191] (3) Operation steps (take 1g resin as an example)

[0192] a. Solid-phase chemical synthesis of peptides

[0193] Weigh 1.00g of 2-CTC resin, put it in the reactor of polypeptide synthesizer, add 10mL DCM, soak for 1h, weigh 2-3 times the amount of Fmoc-AEEAc-OH and absorb 4-6 times the amount of DIEA and add 10mL DCM to dissolve it , put it into the reactor, and carry out the reaction. The reaction temper...

Embodiment 2

[0218] Example 2: Preparation and purification of DMR078-JZH

[0219] Hydrophilic peptide structure: Fmoc-AEEAc-Gly-AEEAc-Gly–AEEAc-OH

[0220] DMR078-JZH structure:

[0221]

[0222] (1) Materials and reagents

[0223] 2-CTC resin, substitution value 0.945mmol / g.

[0224] The amino acids are: Fmoc-AEEAc-OH and Fmoc-Gly-OH

[0225] Synthetic reagents: HATU, DMF, DCM, DIE, piperidine, methyl iodide.

[0226] (2) Instrument

[0227] CS-BIO peptide synthesizer, Waters600 semi-preparative high performance liquid chromatography, Beckman centrifuge, Buchi rotary evaporator.

[0228] (3) Operation steps (take 1g resin as an example)

[0229] a. Solid-phase chemical synthesis of peptides

[0230] Weigh 1.00g of 2-CTC resin, put it in the reactor of polypeptide synthesizer, add 10mL DCM, soak for 1h, weigh 2-3 times the amount of Fmoc-AEEAc-OH and absorb 4-6 times the amount of DIEA and add 10mL DCM to dissolve it , put it into the reactor, and carry out the reaction. The re...

Embodiment 3

[0256] Example 3: Preparation and purification of DMR086

[0257] Hydrophilic peptide structure: Fmoc-AEEAc-AEEAc-OH

[0258] DMR086 structure:

[0259]

[0260] (1) Materials and reagents

[0261] 2-CTC resin, substitution value 0.945mmol / g.

[0262] Amino acid: Fmoc-AEEAc-OH,

[0263] Synthetic reagents: HATU, DMF, DCM, DIEA, piperidine, methyl iodide.

[0264] (2) Instrument

[0265] CS-BIO peptide synthesizer, Waters600 semi-preparative high performance liquid chromatography, Beckman centrifuge, Buchi rotary evaporator.

[0266] (3) Operation steps (take 1g resin as an example)

[0267] a. Solid-phase chemical synthesis of peptides

[0268]Weigh 1.00g of 2-CTC resin, place it in a polypeptide synthesizer reactor, add 10mL DCM, soak for 1h, weigh 2-3 times the amount of Fmoc-AEEA-OH and absorb 4-6 times the amount of DIEA and add 10mL DCM After dissolving, put it into the reactor and carry out the reaction. The reaction temperature is room temperature (25°C and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com