Novel safe environment-friendly lightweight automotive interior material and preparation method thereof

An automotive interior and lightweight technology, applied in the field of safe and environmentally friendly lightweight automotive interior materials and its preparation, can solve the problems of high cost, complicated process and formula, and inability to use adsorption technology, achieving high cost, wide application, craft complex effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

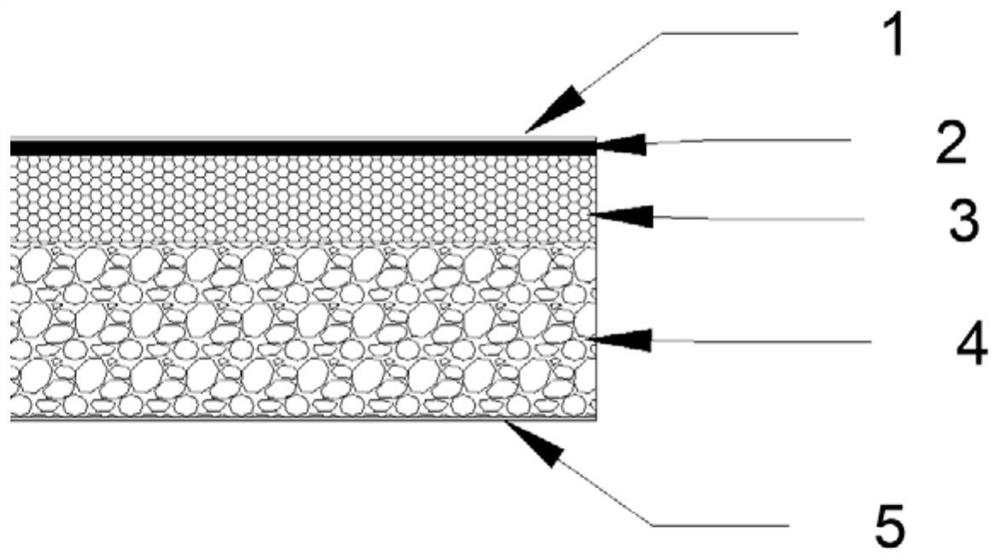

[0037] Such as figure 1 As shown, the lightweight automotive interior material provided in this embodiment includes a surface treatment layer 1, a TPO / TPU blend layer 2, a TPO foam layer 3, a polypropylene foam layer 4, and a back surface treatment layer 5.

[0038] The raw material of the surface treatment layer 1 uses aqueous polyurethane resin.

[0039] The raw material of the back treatment layer 5 is made of 100 parts of a water-based polyurethane resin and 10 parts of the flame retardant.

[0040] When specifically for automotive interior, the material of the polypropylene foam layer 4 is usually a predetermined specification of polypropylene foam material, such as 1.0 mm, 1.5 mm, 2.0 mm, 2.5 mm, 3.0mm, etc., width 400 ~ Between 1300mm, the bubble magnification has 15 / 20 / 25 / 30 times, according to different types of requirements. In this example, the polypropylene foam layer 4 uses a PPFOAM having a specification of 2.0 mm.

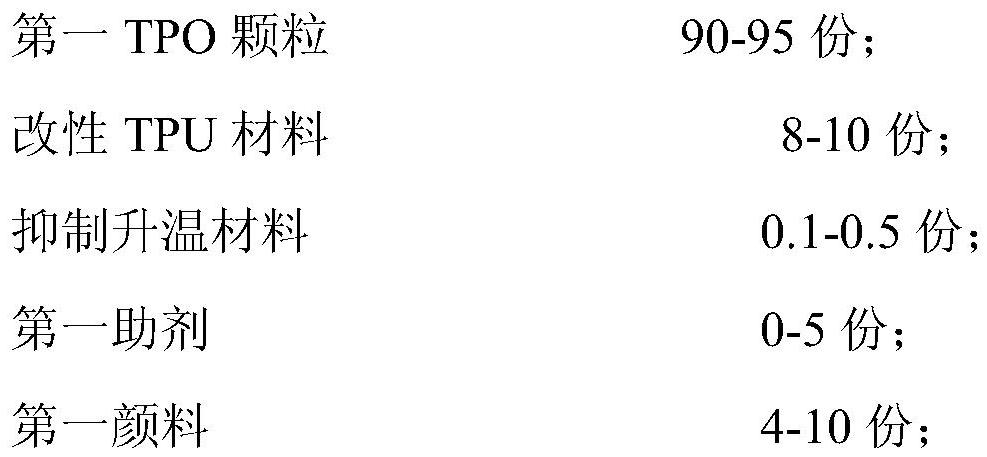

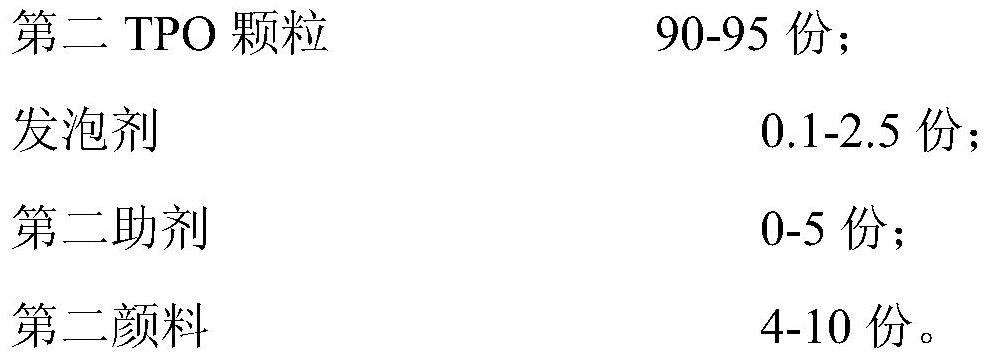

[0041] The raw material formulation of the TPO / ...

Embodiment 2

[0050] The lightweight car interior material provided in this embodiment,

[0051] The raw material of the surface treatment layer 1 uses aqueous polyurethane resin.

[0052]The raw material of the back treatment layer 5 is made of 100 parts of a water polyurethane resin and 8 parts of the flame retardant.

[0053] When specifically for automotive interior, the material of the polypropylene foam layer 4 is usually a predetermined specification of polypropylene foam material, such as 1.0 mm, 1.5 mm, 2.0 mm, 2.5 mm, 3.0mm, etc., width 400 ~ Between 1300mm, the bubble magnification has 15 / 20 / 25 / 30 times, according to different types of requirements. In this example, the polypropylene foam layer 4 uses a PPFOAM having a specification of 2.0 mm.

[0054] The raw material formulation of the TPO / TPU blend layer 2 was 93 parts of TPO, 9 part modified TPUs, 3 partsmatic amine light stabilizers and 6 parts of pigments and 0.3 points inhibited warming materials.

[0055] The raw material f...

Embodiment 3

[0057] The lightweight car interior material provided in this embodiment,

[0058] The raw material of the surface treatment layer 1 uses aqueous polyurethane resin.

[0059] The raw material of the back treatment layer 5 is made of 100 parts of a water-based polyurethane resin and 6 parts of the flame retardant.

[0060] When specifically for automotive interior, the material of the polypropylene foam layer 4 is usually a predetermined specification of polypropylene foam material, such as 1.0 mm, 1.5 mm, 2.0 mm, 2.5 mm, 3.0mm, etc., width 400 ~ Between 1300mm, the bubble magnification has 15 / 20 / 25 / 30 times, according to different types of requirements. In this example, the polypropylene foam layer 4 uses a PPFOAM having a specification of 2.0 mm.

[0061] The raw material formulation of the TPO / TPU blend layer 2 was 95 parts of TPO, 10 part modified TPUs, 1 partially blocked amine light stabilizer and 8 parts of pigments and 0.5 points inhibited warming materials.

[0062] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com