Low-loss type injection mold

An injection mold, low-loss technology, applied in the field of molds, can solve the problems of heat loss, large loss, energy consumption of injection molds, etc., and achieve the effect of improving the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

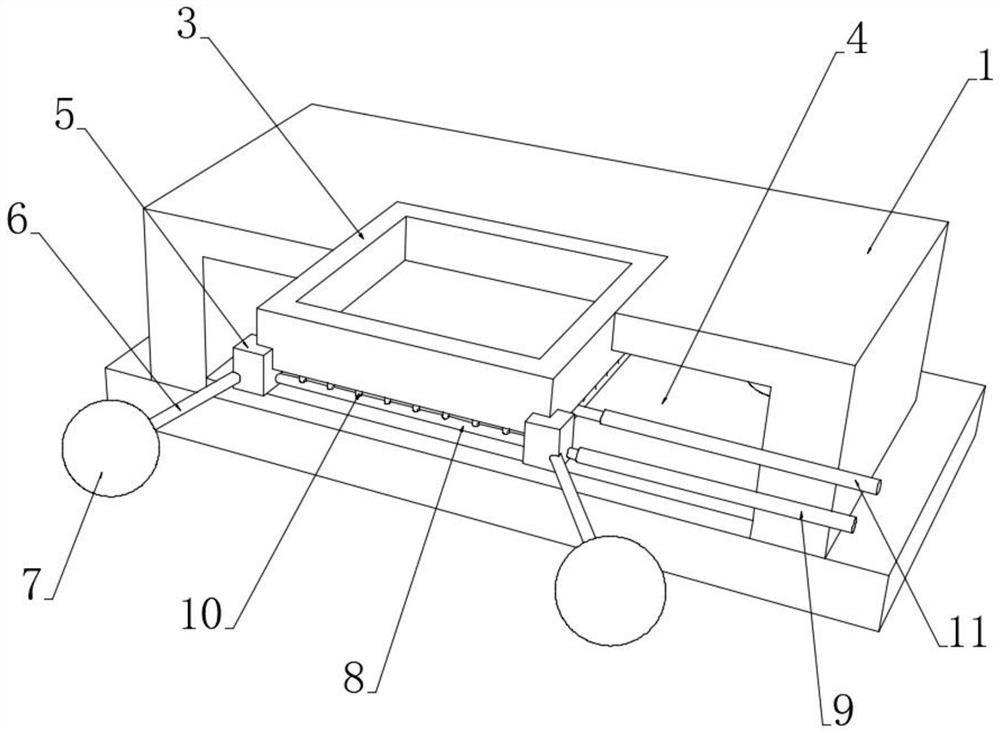

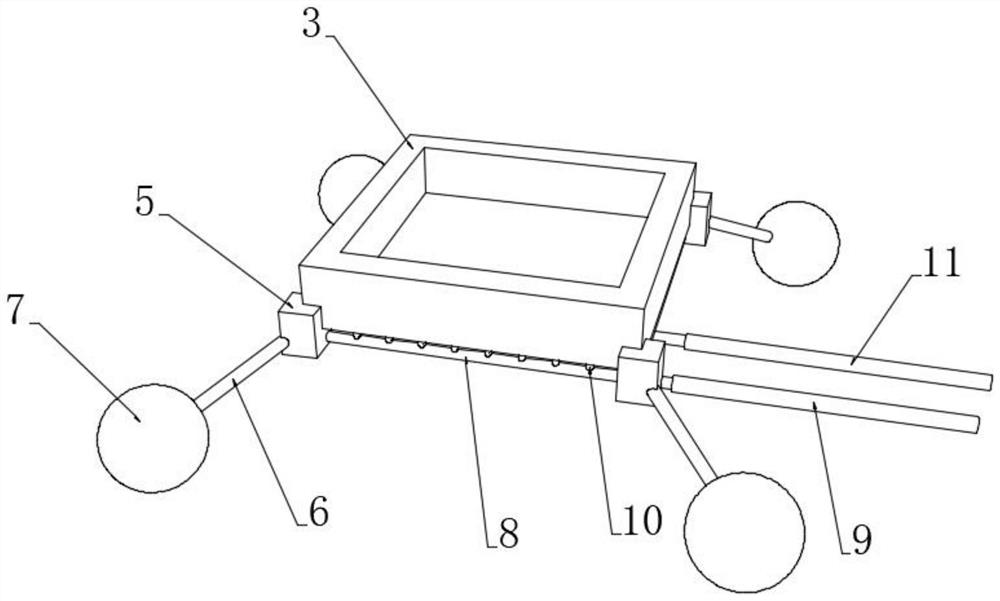

[0046] see Figure 1-5 , a low-loss type injection mold, including an upper template 2 and a lower template 1 arranged up and down, the upper and lower four corners of the lower template 1 are uniformly cylinder electric telescopic rods connected with the bottom four corners of the lower template 1, and the upper end of the lower template 1 is provided with The mold core 3 is provided with a mold cavity, the side wall of the upper formwork 2 is provided with a pouring port connected with the mold cavity, and the inside of the lower formwork 1 is provided with a hollow cavity 4 at the bottom end of the mold core 3, The four corners of the bottom end of the mold core 3 are fixedly connected with conduction seats 5, and the outer ends of a plurality of conduction seats 5 are connected with heat storage bags 7 through heat insulation rods 6, and the inside of heat insulation rods 6 is fixedly connected with heat insulation boards. The upper and lower ends of the heat plate are res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com