High-Mach-number aero-engine compartment and turbine disc combined cooling thermal management system

A thermal management system and engine compartment technology, applied to engine components, machines/engines, mechanical equipment, etc., can solve the problems of accessories not working properly, high temperature of aircraft engine compartment, high temperature of compressor bleed air, etc., to achieve easy modification , reduce heat load, meet the effect of cooling demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

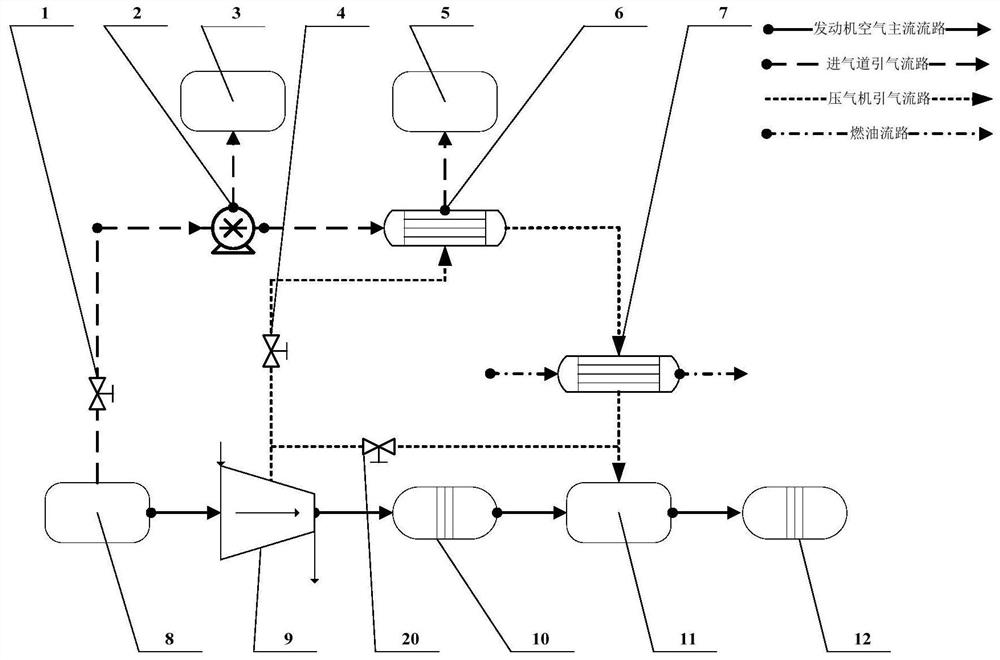

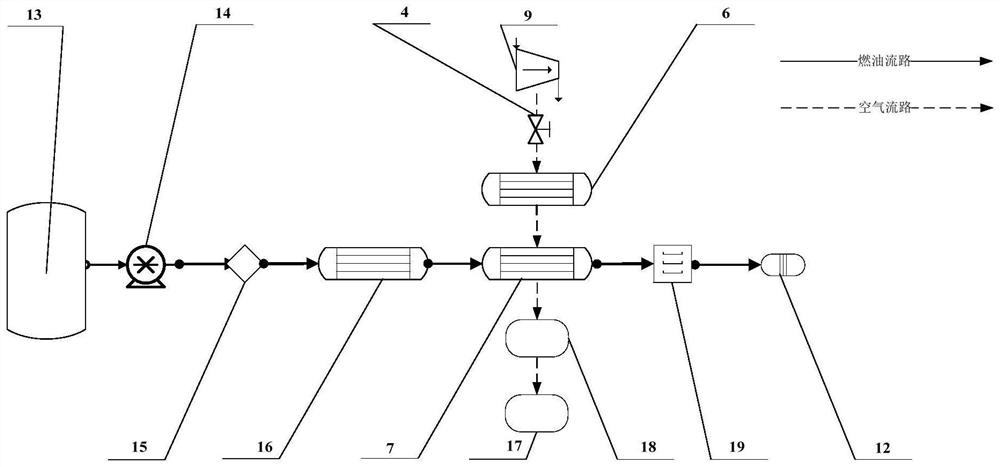

[0032] To solve this problem, this embodiment provides a high Mach number aircraft engine compartment and a combined cooling thermal management system for the turbine disk. The specific implementation is as follows:

[0033](1) When the aeroengine is flying at low speed, close the first control valve 1 and the second control valve 4, and open the third control valve 20. At this time, the system scheme does not work, and the air flow path is the same as that of a conventional engine. From the intake port 8, it flows into the compressor 9, and the main flow of the compressor enters the main combustion chamber 10, then enters the turbine 11, and then enters the afterburner 12. In addition, the compressor bleed air directly enters the turbine 11 for cooling.

[0034] (2) When the aeroengine is flying at a high Mach number, the first control valve 1 and the second control valve 4 are opened, and the third control valve 20 is closed. At this time, the system scheme works.

[0035]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com