Laser perforation processing method for a thick plate

A laser perforation and processing method technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as inability to perforate, unstable perforation, and inability to realize full board cutting, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

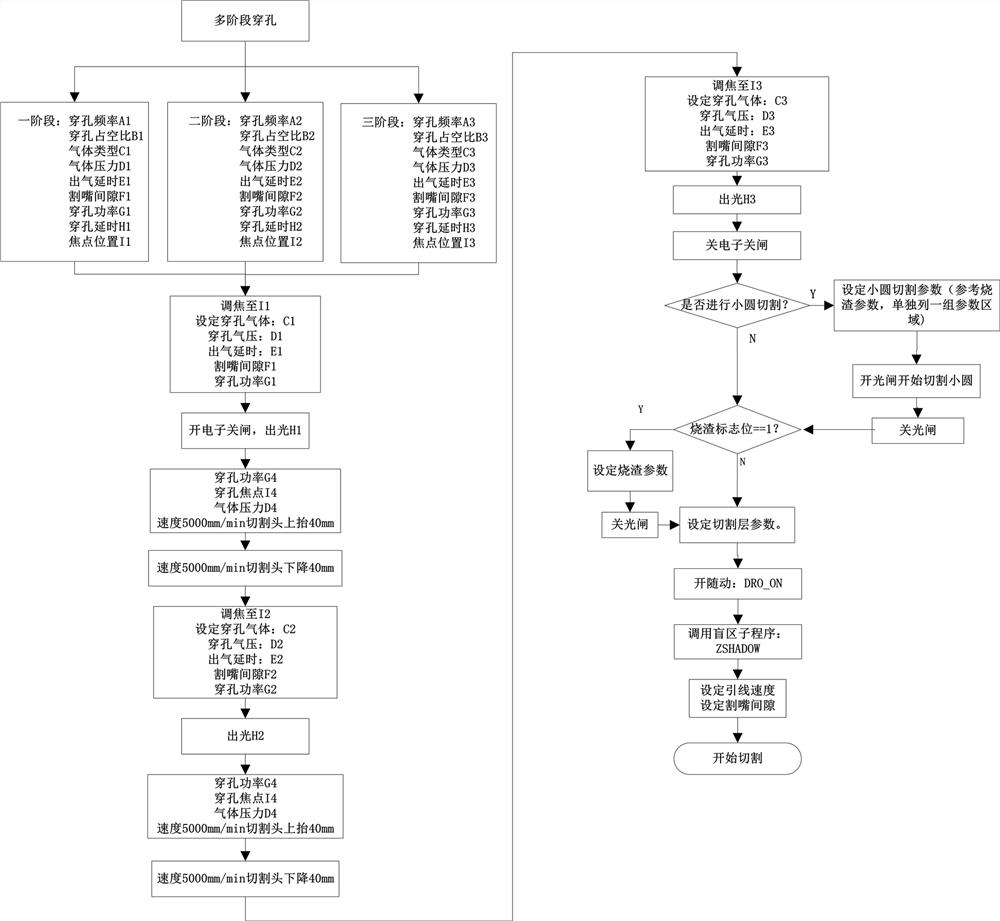

[0019] A thick plate laser perforation processing method, comprising the following steps:

[0020] Step 1: Read the initial piercing parameters: piercing frequency A1, piercing duty cycle B1, gas type C1, gas pressure D1, gas outlet delay E1, cutting nozzle gap F1, piercing power G1, piercing delay H1 and focus position I1;

[0021] Step 2: Read the target piercing parameters: piercing frequency A2, piercing duty cycle B2, gas type C2, gas pressure D2, gas outlet delay E2, cutting nozzle gap F2, piercing power G2, piercing delay H2 and focus position I2 ;

[0022] Step 3: Read target piercing parameters: piercing frequency A3, piercing duty cycle B3, gas type C3, gas pressure D3, gas outlet delay E3, cutting nozzle gap F3, piercing power G3, piercing delay H3 and focus position I3 ;

[0023] Step 4: Adjust the focus, set the focus to I1, set the perforation gas: C1, perforation air pressure: D1, gas output delay: E1, cutting nozzle gap F1 and perforation power G1, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com