High-speed motorized spindle thermal error modeling method based on bonding graph

A technology of high-speed electric spindle and modeling method, applied in simulators, instruments, computer control, etc., can solve problems such as large errors in analysis results, inability to analyze singular points, difficulty in obtaining mathematical models, etc., and achieve fast operation speed, Facilitate the effect of multiple analogy analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

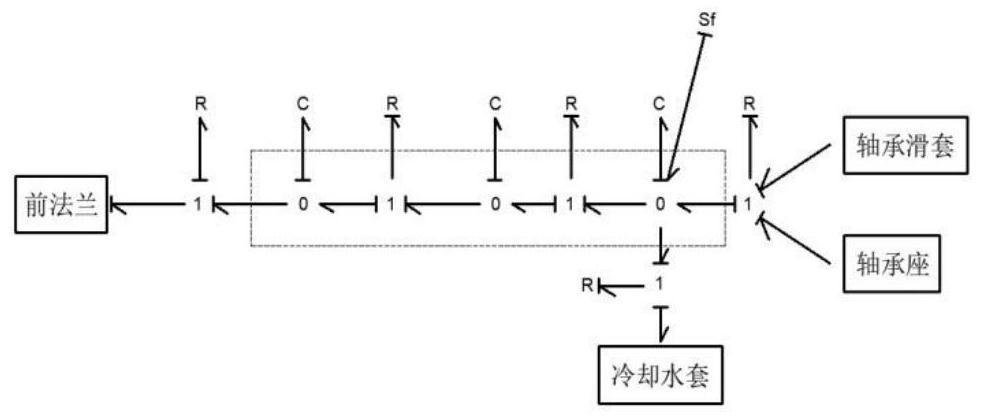

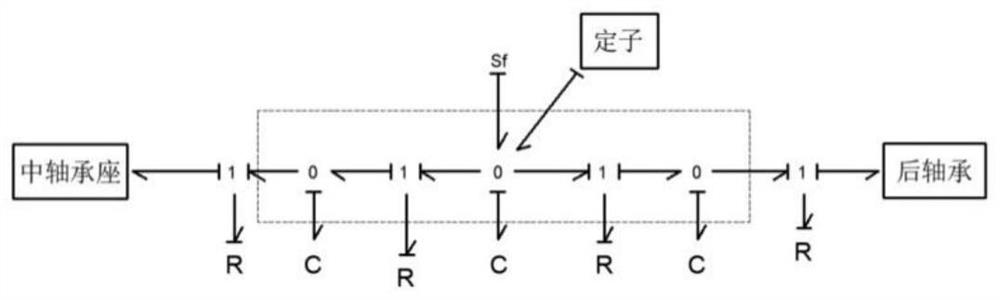

[0023] The present invention provides a high-speed motorized spindle modeling method based on a bonding graph. In order to make the present invention more obvious and understandable, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0024] The temperature field of the thermal error system of the high-speed electric spindle of the present invention mainly includes the bearing part, the stator part and the rotor part. The positional relationship between all bond graph models is connected with standard bond graph components, thereby constructing a complete bond graph model of the temperature field of the high-speed electric spindle thermal error system, and further establishing a high-speed electric spindle thermal error mathematical model, according to the model Carry out system simulation and analysis to obtain the size of the thermal error of the high-speed electric spindle. The main steps are as fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com