Vertical shaft construction method for promoting fracture dislocation and improving self-supporting capacity

A construction method and self-supporting technology, which is applied in directional drilling, earthwork drilling, wellbore/well components, etc., can solve the problems that are not conducive to the self-supporting of hydraulic fractures, and cannot generate enough misalignment slippage, etc., to achieve the realization of The effect of the self-supporting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

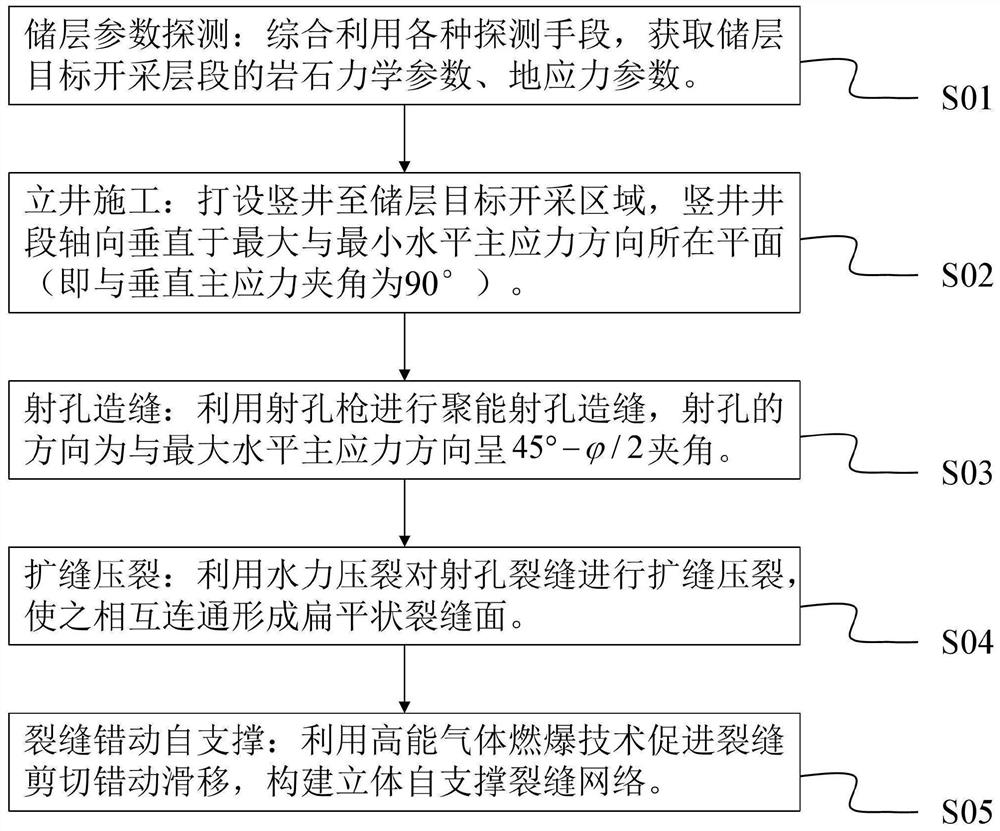

[0105] Taking a certain shale reservoir as an example, a shaft construction method provided by the present invention to promote fracture dislocation and improve self-supporting ability is adopted, such asfigure 1 As shown, the main steps are as follows:

[0106] (a) Reservoir parameter detection. The various parameters of shale reservoir rock mechanics and in-situ stress in the described embodiment are as shown in Table 1:

[0107] Table 1 Reservoir parameters

[0108]

[0109]

[0110] (b) shaft construction;

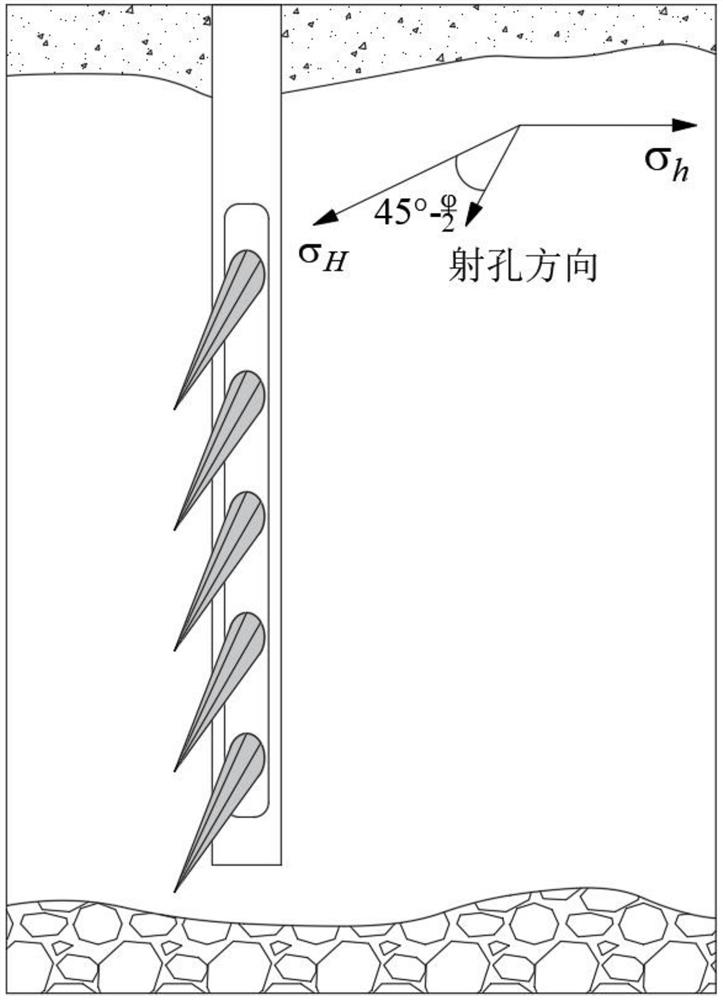

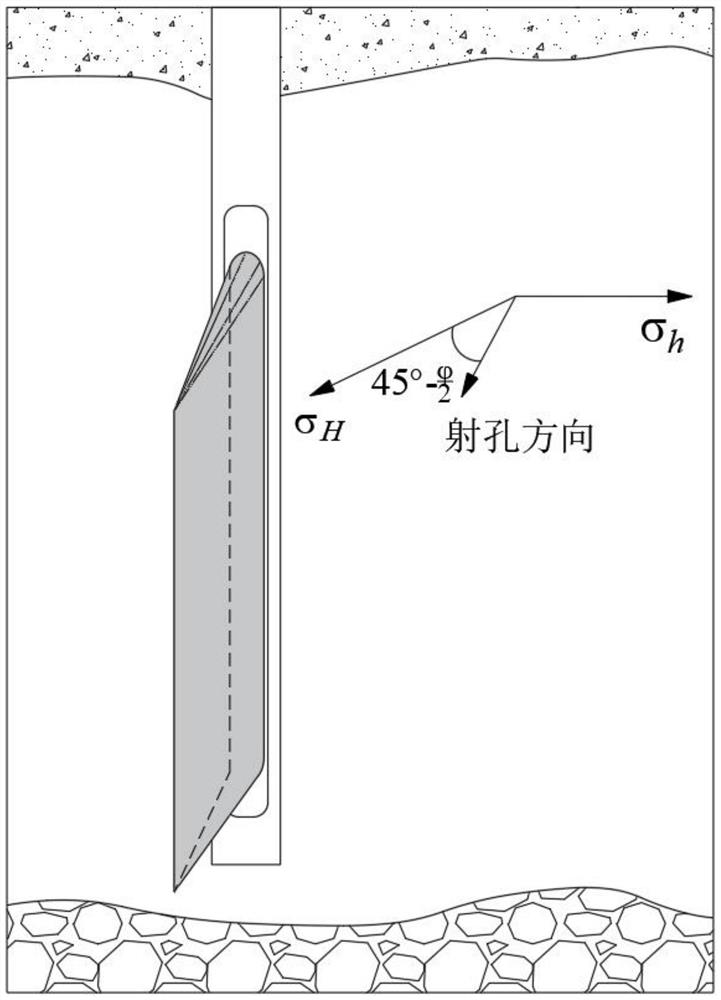

[0111] (c) Perforation and fracture creation. In order to explore the relationship between the fracture angle generated by perforation and the dislocation slip of the fracture under the in-situ stress field of the original rock, the opening degree and dislocation degree of the fracture surface were analyzed. The force analysis included the vertical principal stress, the maximum Horizontal principal stress, minimum horizontal principal stress, effective compres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com